Array lens manufacturing method, array lens, and array lens unit

A technology of array lens and manufacturing method, which is applied in the direction of lens, optical element, instrument, etc., and can solve problems such as the complexity of super-resolution processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, an array lens and the like according to one embodiment of the present invention will be described with reference to the drawings.

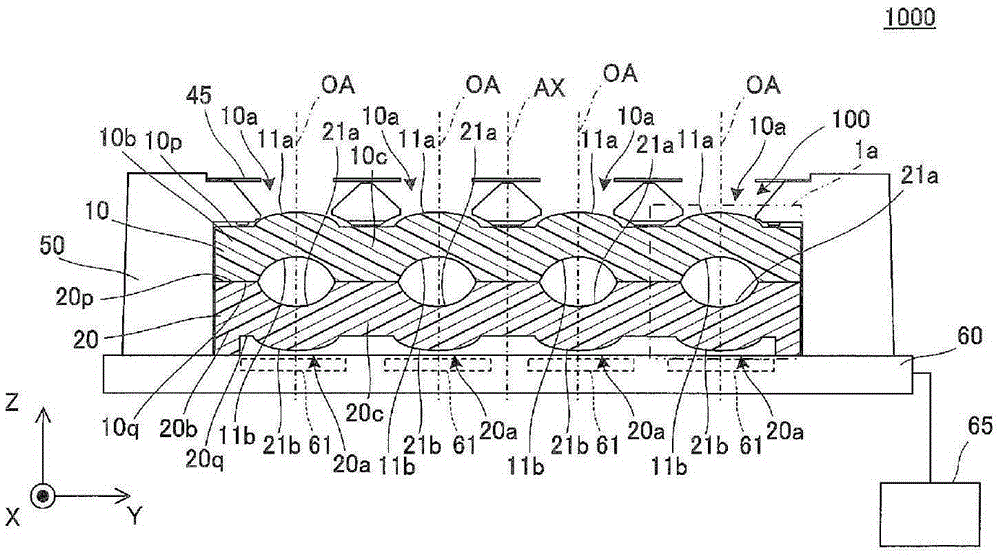

[0021] Such as Figure 1A As shown in and 1B , the stacked array lens unit 100 is assembled in the imaging device 1000 .

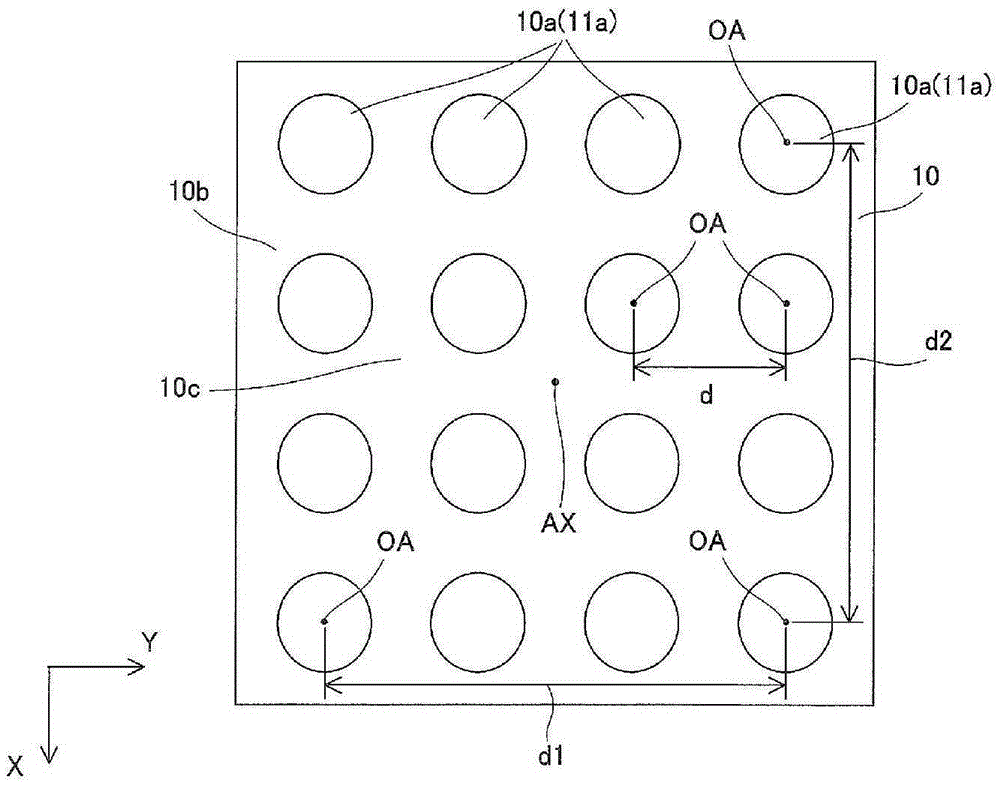

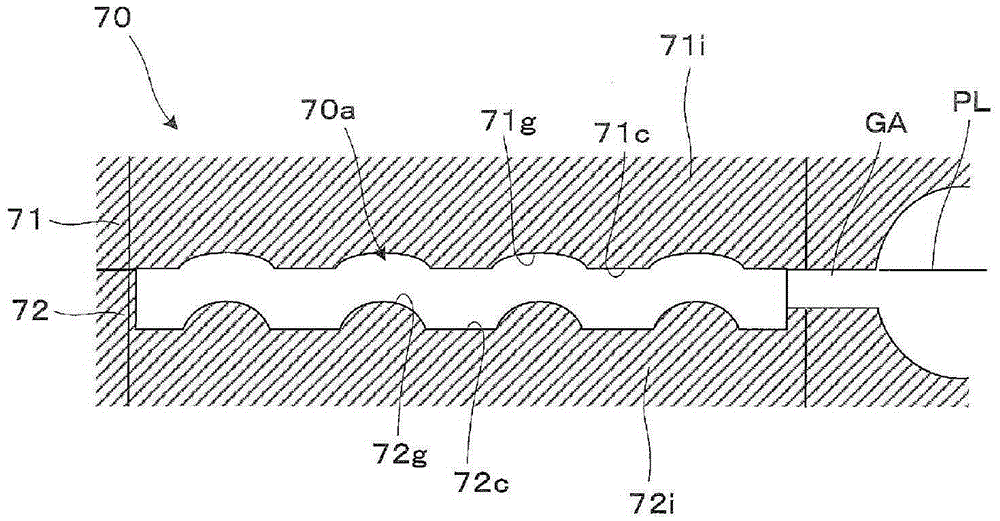

[0022] The illustrated stacked-type array lens unit 100 is a stacked body in which a plurality (specifically, two) array lenses 10 and 20 are stacked, and is used as a fly-eye optical system. The first and second array lenses 10 and 20 are square plate-shaped members extending parallel to the XY plane, and are stacked in the Z-axis direction perpendicular to the XY plane to be bonded to each other.

[0023] In addition, the imaging device 1000 includes, in addition to the array lens unit 100 described above, a sensor array 60 having a plurality of detection units (sensor elements) 61 provided corresponding to the respective synthetic lenses 1 a constituting the array lens unit 100 , and an image sensor arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com