Manufacturing method of ultralow-temperature instantaneous cooling ice bag

A production method and ultra-low temperature technology, which can be applied to cooling appliances for therapeutic treatment, heating appliances for therapeutic treatment, contraceptive appliances, etc. The effect of low management cost and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: The making and use of ultra-low temperature instant cooling ice pack

[0025] (1) Make 100g ice packs

[0026] A. Use OPP+PE composite film to make the inner water bag, fill it with 40ml of water, heat seal it to make the inner water bag;

[0027] B. 45g of urea and 15g of ammonium chloride are packed in the nylon composite outer bag;

[0028] C. Put the inner water bag into the nylon composite outer bag, heat seal the outer bag, and get 100g of ice bag finished product.

[0029] (2) Make 120g ice packs:

[0030] A. Use PET+PE composite film to make the inner water bag, fill it with 50ml of water, heat seal it to make the inner water bag.

[0031] B. Put 50g of urea and 20g of ammonium chloride into a nylon composite outer bag.

[0032] C. Put the inner water bag into the nylon-nylon composite outer bag, and seal it with heat to obtain a finished product of 120g ice bag.

[0033] When using the ice packs of the above specifications, pinch the inner wa...

Embodiment 2

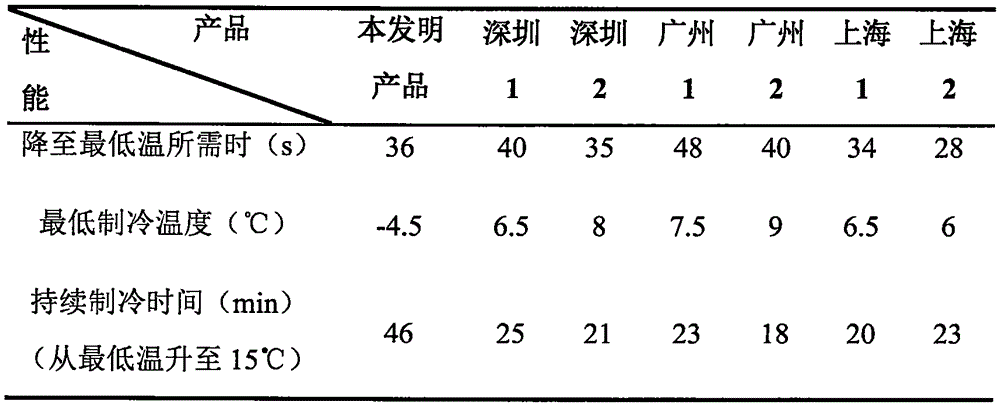

[0034] Embodiment 2: Performance comparison of ultra-low temperature instant cooling ice packs

[0035] The inventor compares the product of the present invention with a plurality of products currently on the market. Samples from two different manufacturers were taken from Shenzhen, Guangzhou, and Shanghai for comparison. The samples were left at room temperature for 2 hours to bring the sample mass to the same temperature as room temperature. In order to make the products comparable, the inventor took a beaker of the same size, poured the material into the beaker first, then cut the corresponding water bag, poured it into the beaker, started timing, stirred at an even speed to the lowest temperature, and stopped stirring. , to record the time. And observe the temperature situation, record the time required for the product to rise from the lowest temperature to 15 degrees. The comparison results are as follows:

[0036]

[0037] Through the comparison of experimental re...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap