Ultrahigh-purity gas dilution system

A pure gas, ultra-high technology, applied in the direction of gas and gas/steam mixing, mixer, mixing method, etc., to reduce the risk of uneven gas mixing, increase outlet pressure, and expand the range of dilution ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

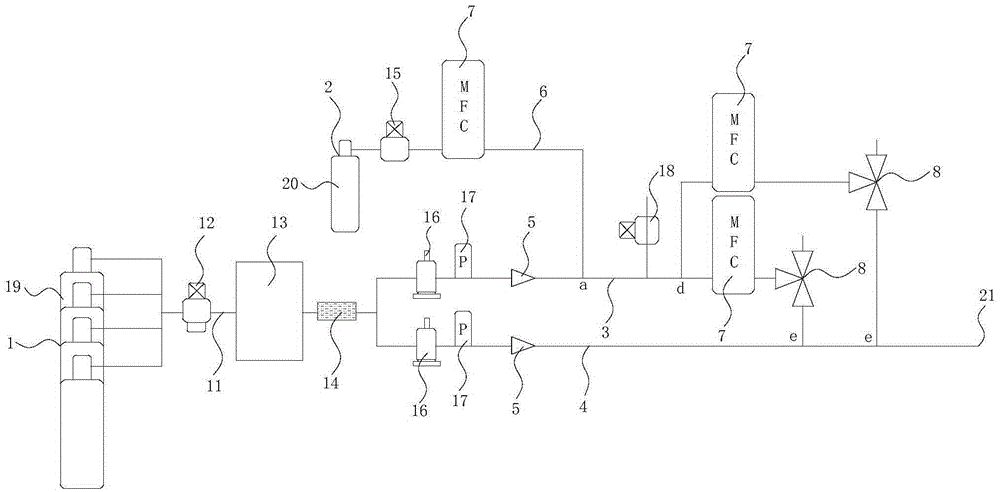

[0022] In this embodiment, an ultra-high-purity gas dilution system is provided, which is used to dilute the existing gas standard with higher concentration to a gas standard with lower concentration, such as figure 1 As shown, it includes a dilution gas source 1 and a gas to be diluted source 2, wherein the dilution gas source 1 contains a dilution gas, and the gas to be diluted source 2 contains a gas to be diluted. In this embodiment, through multiple mixing and dilution of the above two gases, a gas standard that meets the requirements is finally obtained.

[0023] The dilution gas source 1 is connected with a first dilution gas pipeline 3 and a second dilution gas pipeline 4, which divide the dilution gas in the dilution gas source 1 into two paths for subsequent dilution; specifically, the dilution gas A pipeline 11 is arranged between the source 1 and the first diluent gas pipeline 3 and the second diluent gas pipeline 4, and the diluent gas in the diluent gas source 1 ...

Embodiment 2

[0058] This embodiment is improved on the basis of embodiment 1, specifically:

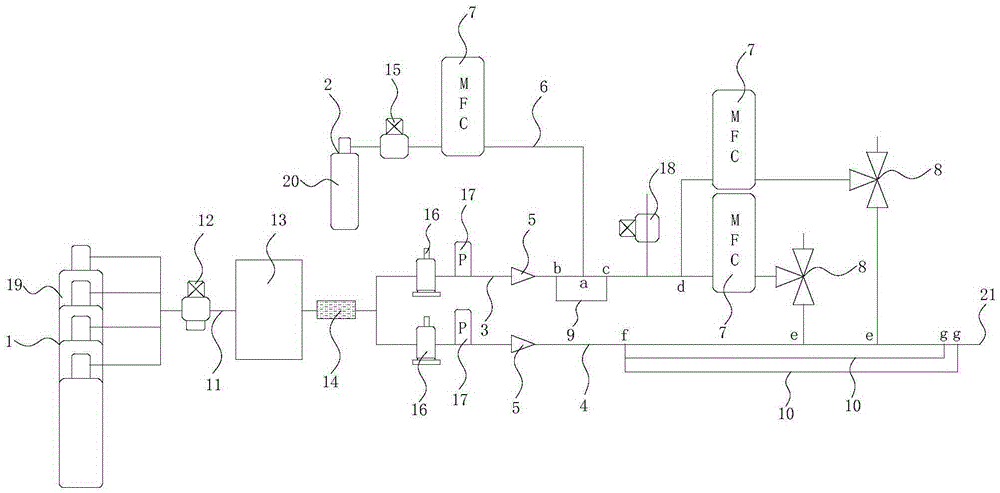

[0059] Such as figure 2 As shown, in this embodiment, at least one first branch pipeline 9 is provided on the first dilution gas pipeline 3, and the communication point a between the gas pipeline to be diluted 6 and the first dilution gas pipeline 3 is located in the first branch pipeline 9 and the two connection points b and c of the first dilution gas pipeline 3, in this embodiment, the connection point between the inlet of the first branch pipeline 9 and the first dilution gas pipeline 3 is set as the connection point b, The connection point between the outlet of the first branch pipeline 9 and the first dilution gas pipeline 3 is set as a connection point c, and the connection point a is located between the connection point b and the connection point c. When multiple first branch pipelines 9 are set, the outer first branch pipeline 9 wraps the inner first branch pipeline 9, and the connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com