An Ultra High Purity Gas Dilution System

A pure gas, ultra-high technology, used in gas and gas/vapor mixing, mixers, mixing methods, etc., to save consumption, expand the range of dilution ratios, and increase outlet pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

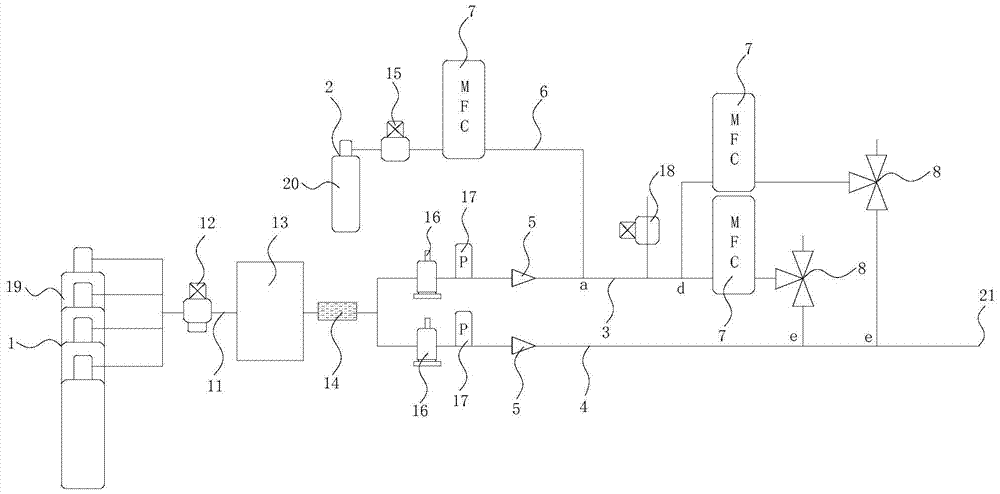

[0022] This embodiment provides an ultra-high-purity gas dilution system for diluting an existing gas standard with a higher concentration into a gas standard with a lower concentration, such as figure 1 As shown, it includes a dilution gas source 1 and a to-be-diluted gas source 2, wherein the dilution gas source 1 contains the dilution gas, and the to-be-diluted gas source 2 contains the gas to be diluted. In this embodiment, the gas standard that meets the requirements is finally obtained through multiple mixing and dilution of the above two gases.

[0023] The dilution gas source 1 is connected with the first dilution gas pipeline 3 and the second dilution gas pipeline 4, and the dilution gas in the dilution gas source 1 is divided into two paths for transportation for subsequent dilution; A pipeline 11 is set between the source 1 and the first diluent gas pipeline 3 and the second diluent gas pipeline 4, and the diluent gas in the diluent gas source 1 is transported to th...

Embodiment 2

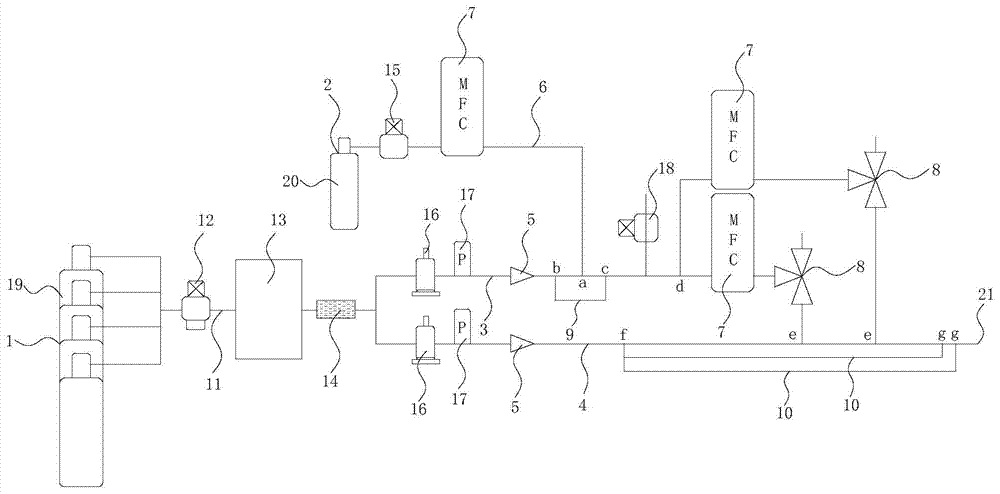

[0058] This embodiment is improved on the basis of Embodiment 1, specifically:

[0059] like figure 2 As shown, in this embodiment, at least one first branch pipeline 9 is provided on the first dilution gas pipeline 3, and the communication point a between the gas pipeline 6 to be diluted and the first dilution gas pipeline 3 is located in the first branch pipeline 9 and the two communication points b and c of the first dilution gas pipeline 3, in this embodiment, the connection point between the inlet of the first branch pipeline 9 and the first dilution gas pipeline 3 is set as the communication point b, The communication point between the outlet of the first branch pipe 9 and the first dilution gas pipe 3 is set as the communication point c, and the communication point a is located between the communication point b and the communication point c. When there are multiple first branch pipelines 9, the first branch pipeline 9 on the outside wraps the first branch pipeline 9 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com