Microporous ceramic catalyst carrier and preparation method thereof

A technology of catalyst carrier and microporous ceramics, which is applied in the direction of catalyst carrier, chemical instrument and method, physical/chemical process catalyst, etc., can solve the problem of low universality of catalyst carrier, achieve small density, strong scalability, and The effect of low grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

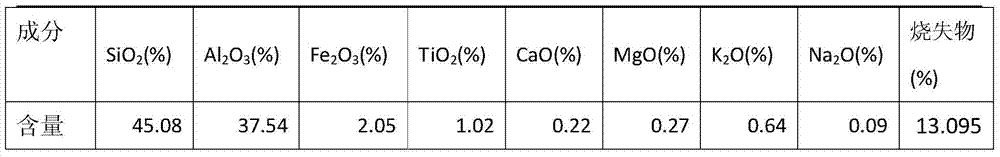

[0033] Formula: 78% mass fraction, 300-mesh low-quality bauxite 700°C light-fired material, the composition and mass fraction after light-fired are shown in Table 1.

[0034] Table 1 Composition of bauxite after light burning

[0035] Element

SiO 2 (%)

al 2 o 3 (%)

Fe 2 o 3 (%)

TiO 2 (%)

CaO(%)

MgO(%)

K 2 O(%)

Na 2 O(%)

Ignition loss (%)

content

50.14

44.31

2.84

1.19

0.35

0.22

0.25

0.10

0.60

[0036] Additive, mass fraction 21.1%, purity>99% water-soluble starch.

[0037] Dispersant, mass fraction 0.9% sodium polyacrylate.

[0038] Process:

[0039] (1) Lightly burn low-quality bauxite at 700° C., refine it to 300 mesh by ball milling, add additives with a mass fraction of 21.1% and 0.9% dispersant and mix uniformly to obtain a mixture;

[0040] (2) Add 80% of the mixture to the EIRICH vertical granulator for granulation, add 21% of atomized water, run at 5000rpm / min for 10mi...

Embodiment 2

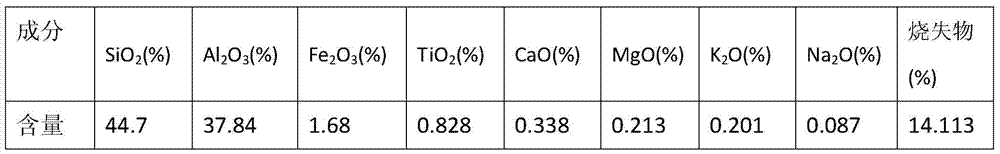

[0046] Formula: 84% mass fraction, 250 mesh low-quality bauxite 800°C lightly fired material, the composition after lightly fired is shown in Table 2.

[0047] Table 2 Composition of bauxite after light burning

[0048]

[0049] Additives, mass fraction 15%. Purity>99% water-soluble starch.

[0050] Dispersant, mass fraction 1.0% sodium polyacrylate.

[0051] Process:

[0052] (1) Low-quality bauxite is lightly burned at 800°C, ball milled to refine it to 250 mesh, and 15% of additives and 1.0% of dispersant are added to mix uniformly to obtain a mixture;

[0053] (2) Add 84% of the mixture to the EIRICH vertical granulator for granulation, add 18% of atomized water, run at 2500rpm / min for 15min to nucleate; run at 1000rpm / min for 50min to grow and form; Polish at 500rpm / min for 30min, add dry mixture powder with a mass fraction of 16%, and adjust the morphology.

[0054] (3) Dry the semi-finished ceramsite product at 105°C for 45 minutes, control the moisture to less ...

Embodiment 3

[0059] Formula: 87% mass fraction, 200-mesh low-quality bauxite 900°C light-fired material, the composition after light-fired is shown in Table 3.

[0060] Table 3 Composition of bauxite after light burning

[0061]

[0062] Additives, mass fraction 12%. Purity>99% water-soluble starch.

[0063] Dispersant, mass fraction 1.0% sodium polyacrylate.

[0064] Process:

[0065] (1) Low-quality bauxite is lightly burned at 900°C, ball milled to refine it to 200 mesh, and 12% of additives and 1.0% of dispersant are added by mass fraction and mixed uniformly to obtain a mixture;

[0066] (2) Add 90% of the mixture to the EIRICH vertical granulator for granulation, add 17% of atomized water, run at 5000rpm / min for 20min to nucleate; run at 2500rpm / min for 60min to grow and form; Polish at 1000rpm / min for 25min, add dry mixture powder with a mass fraction of 10%, and adjust the morphology.

[0067] (3) Dry the semi-finished ceramsite product at 105°C for 45 minutes, control the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com