Hinge-tooth pelletizer

A granulator and hinge tooth technology, applied in the direction of mold extrusion granulation, etc., can solve the problems of long maintenance of equipment, failure to meet process requirements, and influence on normal production, etc., to shorten maintenance time, prolong service life, and improve particle size strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

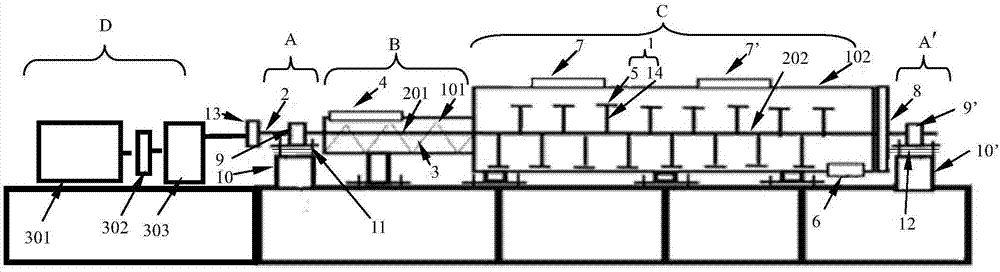

[0019] Hinge tooth granulator, including co-main shaft 2 and driving device D, first supporting assembly A, feeding section device B, extrusion section device C and second supporting assembly A' arranged in sequence; said feeding section device B The end away from the side of the first support assembly A is connected to the end of the extrusion section device C away from the side of the second support assembly A'; the end of the feed section device B near the side of the first support assembly A is in a sealed state; Said extruding section device C is provided with a seal head 8 at one end close to the side of the second support assembly A'; said first support assembly A includes a first bearing chamber 9 and a first support seat 10, and the second support assembly A 'includes the second bearing chamber 9' and the second bearing seat 10'; the two journals of the main shaft 2 are respectively located in the first bearing chamber 9 and the second bearing chamber 9';

[0020] The...

Embodiment 2

[0026] On the basis of embodiment 1, this hinge tooth granulator is further improved:

[0027] The bearing chamber (comprising the first bearing chamber 9 and the second bearing chamber 9') is connected with the supporting seat (including the first supporting seat 10 and the second supporting seat 10') through fixing bolts 11, and the fixing bolt 11 is connected with the two U-shaped silicon steel sheets 12 are arranged between the supporting seats;

[0028] The main shaft 2 is connected with the driving device D by a universal joint 13, and the main shaft 2 moves up and down parallel to the axis of the cylinder, and adjusting the height of the main shaft 2 will not affect its transmission accuracy and efficiency.

[0029] When the working strength of the hinged tooth granulator reaches a certain level, the gap between the hinged tooth 1 and the cylinder body 102 of the extrusion section becomes larger due to friction and needs to be adjusted. At this time, by adjusting the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com