Digital positioning system

A technology of positioning system and positioning column, applied in the direction of positioning device, clamping, supporting, etc., can solve the problems of single positioning or locking of locking device, waste of manpower and material resources, hidden safety hazards, etc., and achieve high reliability and high degree of automation , Operational safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

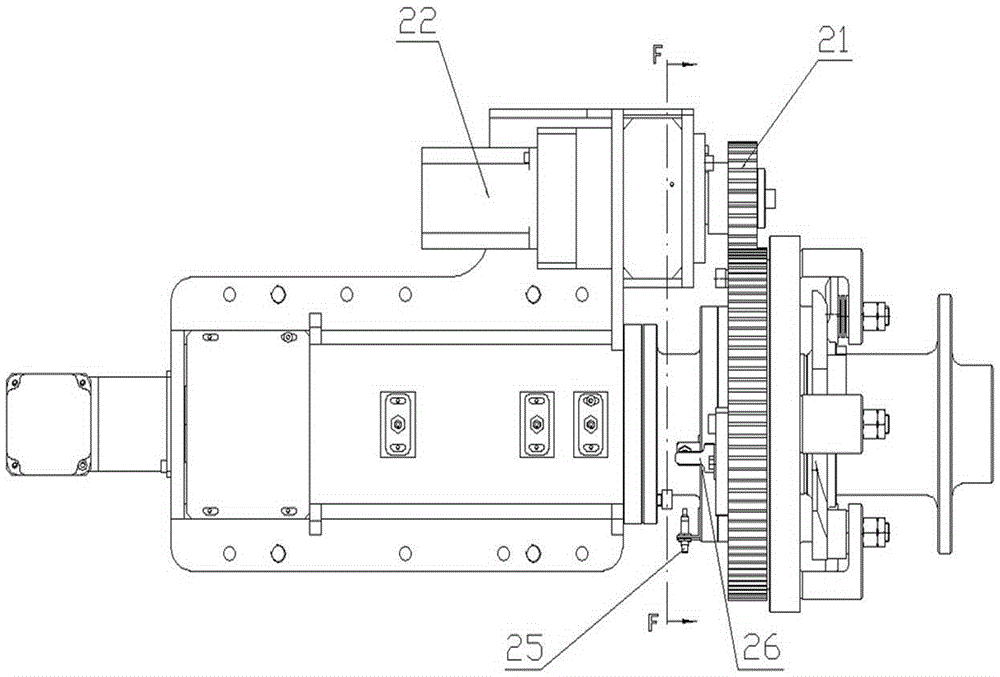

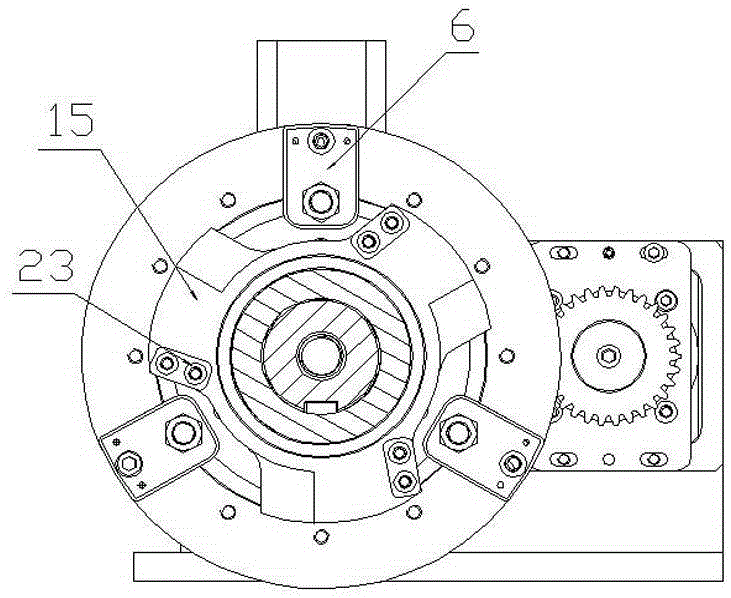

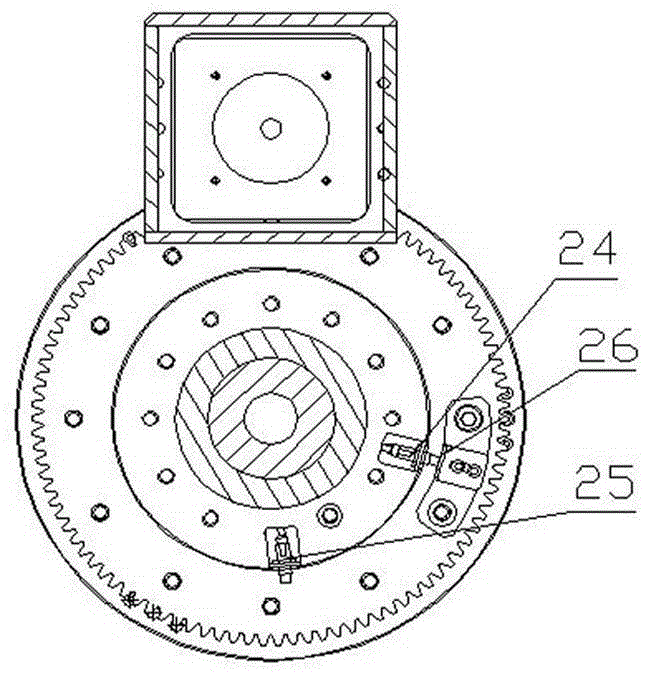

[0018] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. see figure 2 , is a structural schematic diagram of the digital positioning system of the present invention, the digital positioning system of the present invention includes a positioning locking system main body and a locking flange 15, and the positioning mechanism in the positioning locking system main body includes a positioning column arranged inside the housing 19 Sleeve 3, one end of positioning column sleeve 3 connected with shaft coupling 14 is provided with a bearing device, such as figure 2 As shown, the bearing device can be assembled by a two-way thrust bearing 17 and a deep groove ball bearing 18. One end of the trapezoidal screw 2 is installed on the bearing device, and the other end is fixedly connected with the positioning pin 1 with a nut 16. Shaft device 14 links to each other with positioning drive motor 20, as figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com