Automobile generator claw pole positioning clamp

A technology for automotive generators and positioning fixtures, applied in positioning devices, clamping, manufacturing tools, etc., can solve the problems of affecting the generator noise output performance, affecting the dynamic balance of the generator rotor, and unstable claw pole processing, etc., to achieve dynamic Good balance, simple structure, stable processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

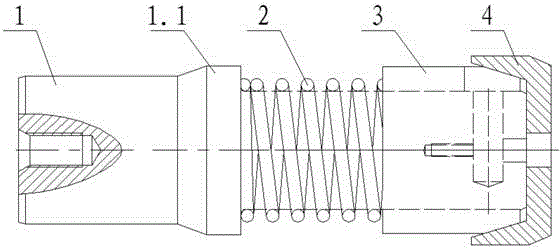

[0009] Such as figure 1 As shown, a claw pole positioning fixture for an automobile generator includes a connecting piece 1, an elastic component 2, and a mandrel 3; one end surface of the connecting piece 1 is provided with a first threaded hole connected to the main shaft of the processing machine tool, and the One end of the connector 1 is sleeved on one end of the elastic member 2; one end of the mandrel 3 is sleeved on the other end of the elastic member 2, and the end of the mandrel 3 away from the elastic member 2 is provided with a The inclined surface matched with the processed claw pole 4; the end of the mandrel 3 far away from the elastic part 2 is provided with a second threaded hole, and the circumferen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com