Reactor seal hot pressing forming method, blank applying method and reactor seal formed by method

A hot-press forming, reactor technology, applied in chemical instruments and methods, forming tools, chemical/physical/physical-chemical processes, etc., can solve the problems of waste of resources, increased transportation weight of steel plates and head transportation, and increased weight. , to reduce the local stress concentration, eliminate the local thinning area, and improve the stress condition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A kind of heating furnace for hot pressing forming head of the present embodiment, such as Figure 4As shown, it includes a furnace roof 21 and a furnace wall 22 surrounding a closed furnace, a hearth 23 and a support pad 25 arranged in the furnace hearth. The stamping easy-to-thinning area of the blank 24 (the local position that does not want to be stamped and thinned when the steel blank is stamped) is provided with a coating mechanism for a high-temperature-resistant and heat-insulating shielding layer. The high-temperature-resistant and heat-insulating shielding layer includes an upper shielding layer 26 and a lower shielding layer. Masking layer 27. It also includes temperature measurement and control thermocouples 29 and 30 for measuring and controlling the temperature of the shielded area and the non-shielded area of the steel blank 24 respectively. Rollers 28 are arranged below the stove base 23. During operation, the furnace base 23 is first pulled out fr...

Embodiment 2

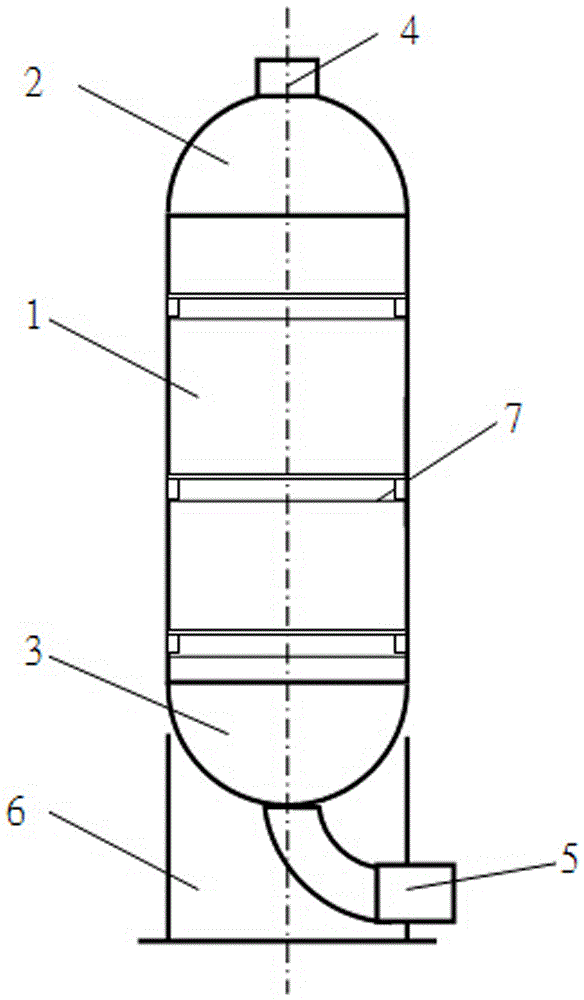

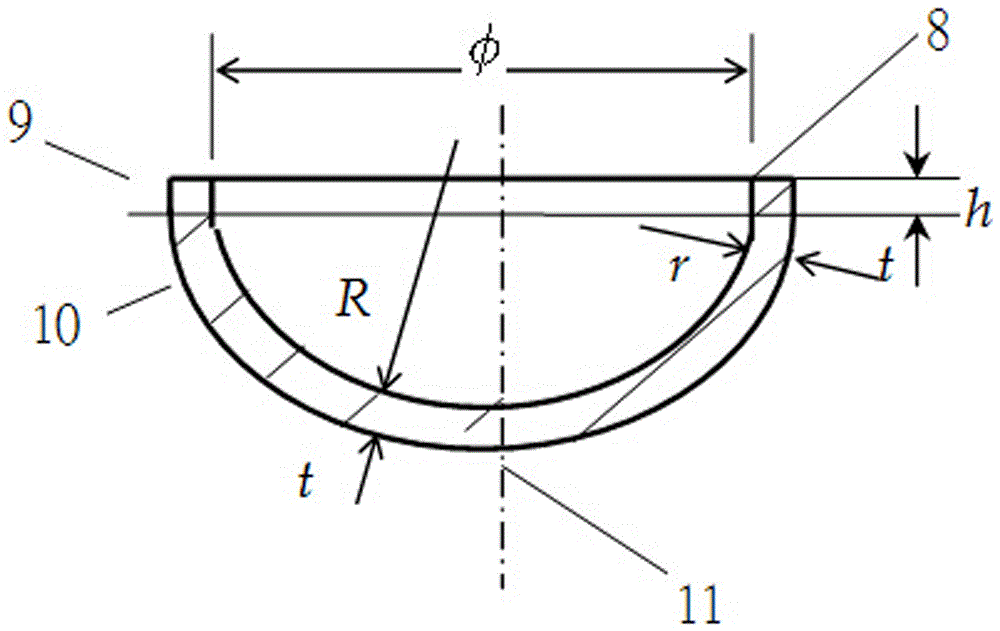

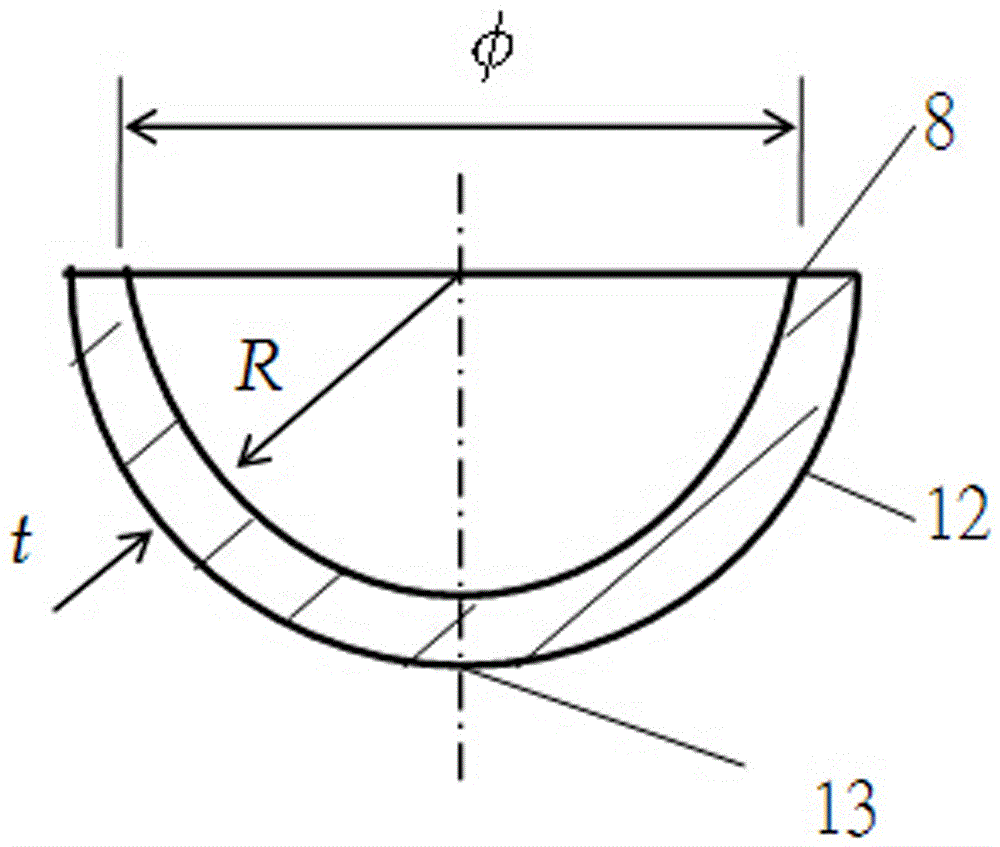

[0056] The second specific implementation of the thermoforming head of this embodiment, the main technical solution of this embodiment is the same as that of Embodiment 1, and the features not explained in this embodiment adopt the explanation in Embodiment 1, and are not omitted here Let me repeat. The difference between this embodiment and embodiment 1 is that, see figure 2 , image 3 and Figure 9 As shown, thermoformed heads include elliptical heads and spherical heads. Among them, the elliptical head includes a straight section 9 forming the head port 8, a spherical bottom section 11 (radius R) forming the top of the head, and a transition section 10 (small radius r) connecting the straight section 9 and the bottom section, The thickness of the straight section 9, the transition section 10 and the top section 11 are equal. The spherical head has a spherical radius R everywhere. Stamping and forming heads by traditional technology generally lead to thinning of wall t...

Embodiment 3

[0058] The third specific implementation of the thermoforming head of this embodiment, the main technical solution of this embodiment is the same as that of Embodiment 2, and the features that are not explained in this embodiment are explained in Embodiment 2, and are not mentioned here Let me repeat. The difference between this embodiment and embodiment 2 is that, see Figure 5 As shown, the head includes a basic thickness area and a local thickening area. Under the same internal pressure, the wall thickness of each part of the entire head corresponds to its stress level. The thickening can be the thickening of the steel blank before the head forming in the corresponding local area (such as Figure 5 The thickening area 31 on the upper surface of the blank and the thickening area 32 on the lower surface of the blank) can also be the thickening caused by controlling a small amount of thinning in a certain local area and a large amount of thinning in other areas during the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com