Process for engine core part bearing cover

A technology of parts and bearing caps, which is applied in the technical field of bearing caps of core parts of the engine, can solve problems such as low efficiency, and achieve the effects of simple connection, high quality of blanks, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

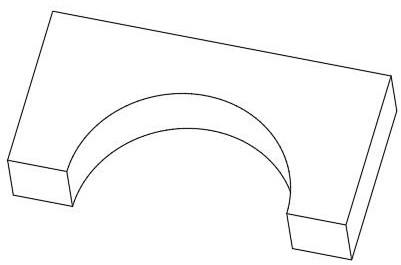

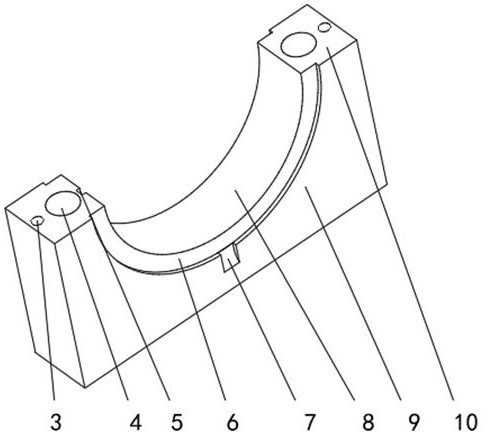

[0036] Such as image 3 As shown, the embodiment of the present invention provides the bearing cover of the core component of the engine, and one end surface of the designated bearing cover is the top surface 10, and the two sides of the top surface 10 are side surfaces 9, and the top surface 10 is provided with bolt holes 4 and positioning pin holes 3 , The bearing cover is provided with a semicircular hole 8, the top surface 10 is provided with a lock tile groove 5, the side surface 9 is provided with a thrust surface 6, and the thrust surface 6 is provided with a thrust groove 7.

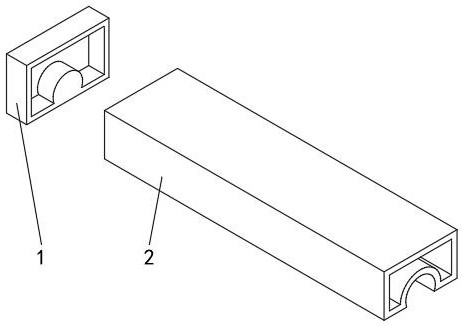

[0037] Bearing cap technology of engine core parts, including casting technology and material removal processing technology, casting technology uses end cap 1 and mold body 2, such as figure 1 As shown, the end cover 1 and the mold main body 2 adopt a transition or clearance fit, and the mold main body 2 is made of metal material. After the mold main body 2 is cast, it expands when heated to achi...

Embodiment 2

[0052] Conduct a survey of step in the dematerialization process and existing processes:

[0053] The traditional process is:

[0054]

[0055] The daily production of traditional crafts is calculated on the basis of an operating rate of 85%, three-shift production, a daily output of 1,200 pieces, an investment of 8.42 million, and 21 workers.

[0056] The parts are 50 components, the customer processing fee is 10 yuan / piece, the labor cost is 260 yuan / day / person, and the manufacturing cost (knife, wind, water, electricity, liquid): 2 yuan / piece.

[0057] Annual gross profit = (1200 pieces / day * 10 yuan / piece - 260 yuan * 21 people - 2 yuan * 1200 pieces) * 350 days = 1.449 million.

[0058] The payback period of investment is 55 months.

[0059] The traditional process has defects such as a large proportion of labor costs, low processing efficiency, and a long payback period.

[0060] Process flow of the present invention is:

[0061]

[0062] The present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com