Alloy gray cast iron piston ring as well as manufacturing method and special template thereof

A manufacturing method and technology of piston rings, applied to piston rings, mechanical equipment, engine components, etc., can solve problems such as complex processes, achieve the effects of improving cavity strength, saving engine oil, and improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

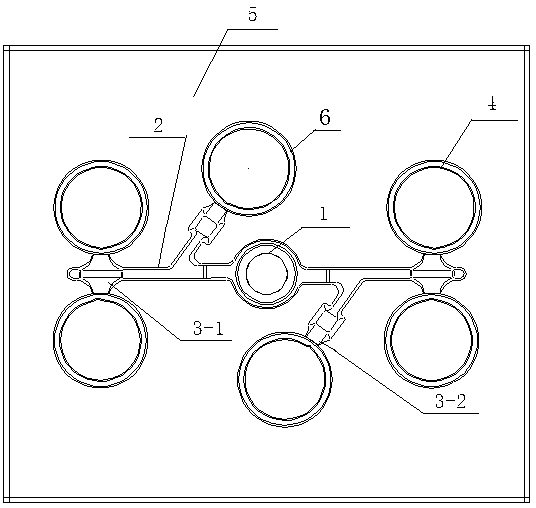

Image

Examples

Embodiment 1

[0025] The material of the present embodiment alloy gray cast iron piston ring is selected suitable C, Si, Mn, P, Cr, Mo, Cu, Ni, the weight percent content of components such as S, and the specific content of each composition is referring to Table 2, and balance is For Fe.

[0026] The manufacture method of alloy gray cast iron piston ring of the present embodiment comprises the following steps:

[0027] a. Molding: The molding sand is a mixture of quartz sand and bentonite. The ratio of the two is shown in Table 1. When the quartz sand is old sand, the volume percentage of bentonite is 1-3%. When the quartz sand is new sand, the bentonite volume The percentage content is 15-20%. When the quartz sand is a mixture of old sand and new sand, the volume percentage of bentonite increases by 1.5-2% for every 10% increase in new sand. The specific requirements are: 1) SiO2 of quartz sand 2 Content ≥ 98%, particle size 75-150 mesh, refractoriness ≥ 1700°C, mud content ≤ 1%; 2) Bent...

Embodiment 2~12

[0040] See Table 2 for the weight percentage of each component in these examples, and its production method and process are the same as those in Example 1 above. The mechanical properties of the products of these examples are shown in Table 3.

[0041] The above examples and batch production tests have proved that the casting mechanical properties of the alloy gray cast iron piston ring manufactured by the new material and the new production process have been greatly improved, and the cast blank has reached The performance requirements that originally required quenching and tempering treatment to be realized. Not only the processing flow is shortened, the labor efficiency is improved, but also the manufacturing cost is reduced. For example, to produce piston rings made of other materials that require quenching and tempering treatment, 100,000 pieces of FZ9842 for each quenching and tempering treatment requires about 14,330 kilowatt-hours of electricity, and the electricity co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com