A Manipulator Based on Electromagnetic Drive

An electromagnetic drive and manipulator technology, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of inaccurate positioning of mechanical designation, increase of equipment weight, virtual swing of fingers, etc., to achieve convenient layout, good practical prospects, and simplified structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

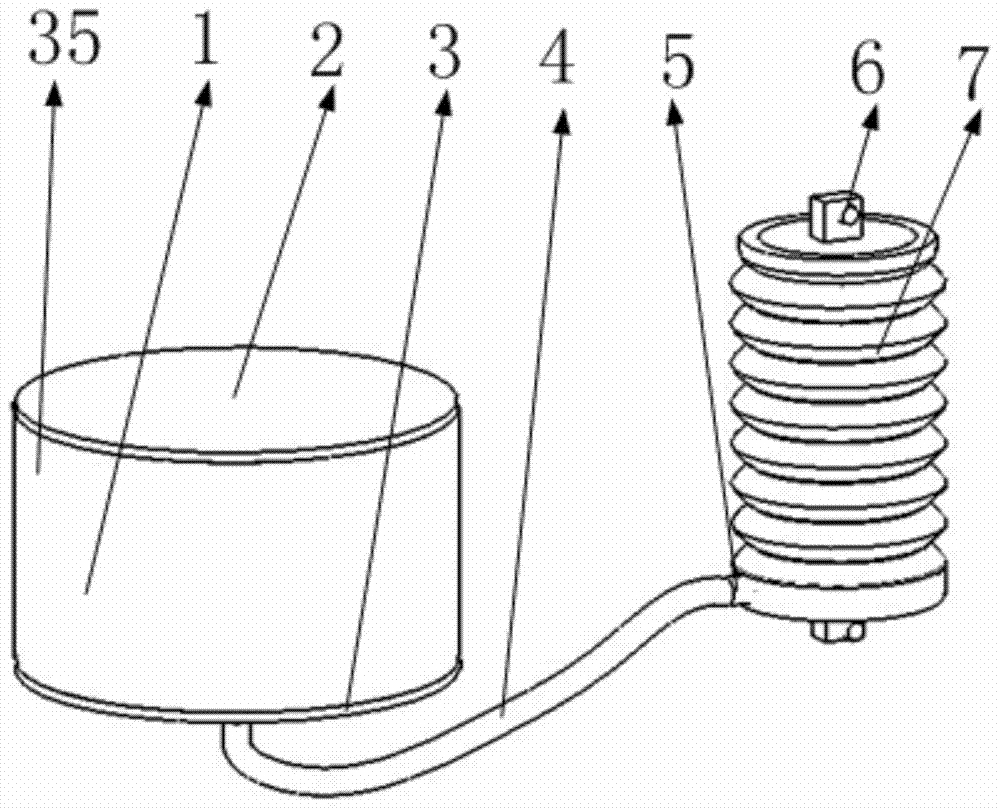

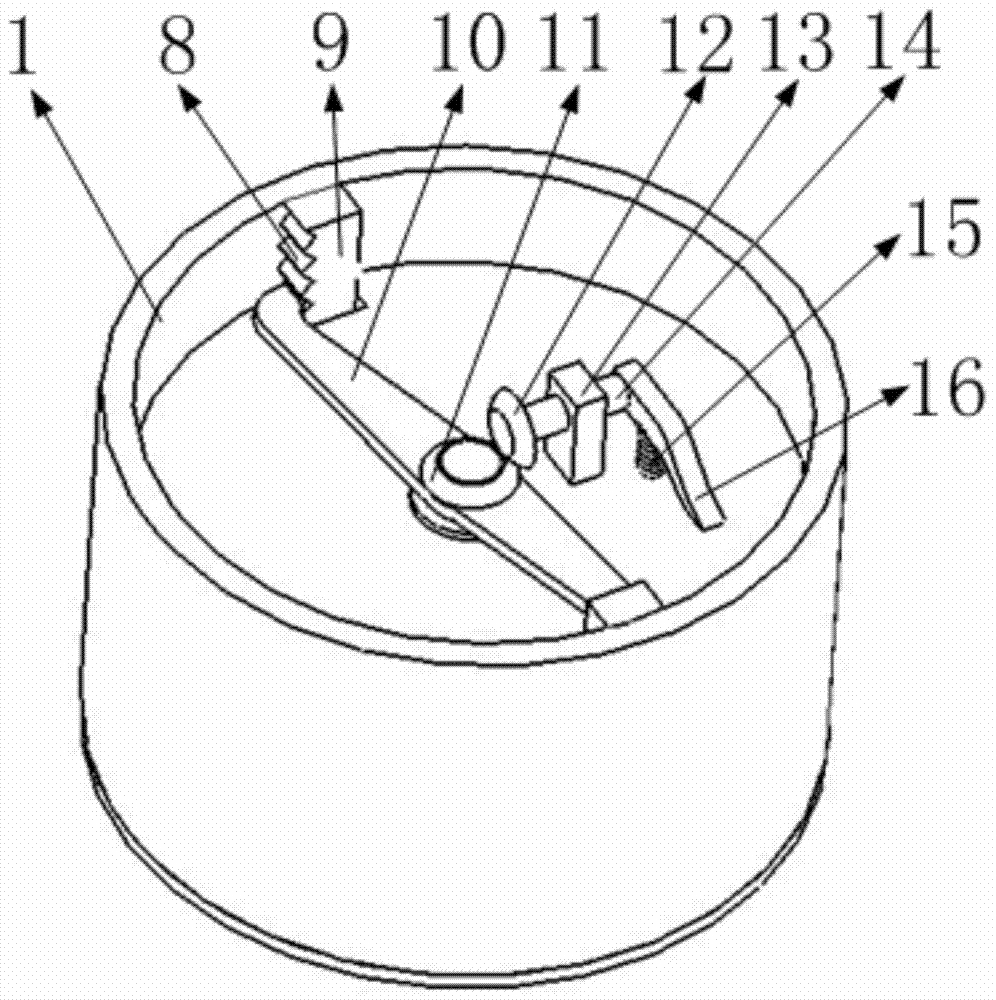

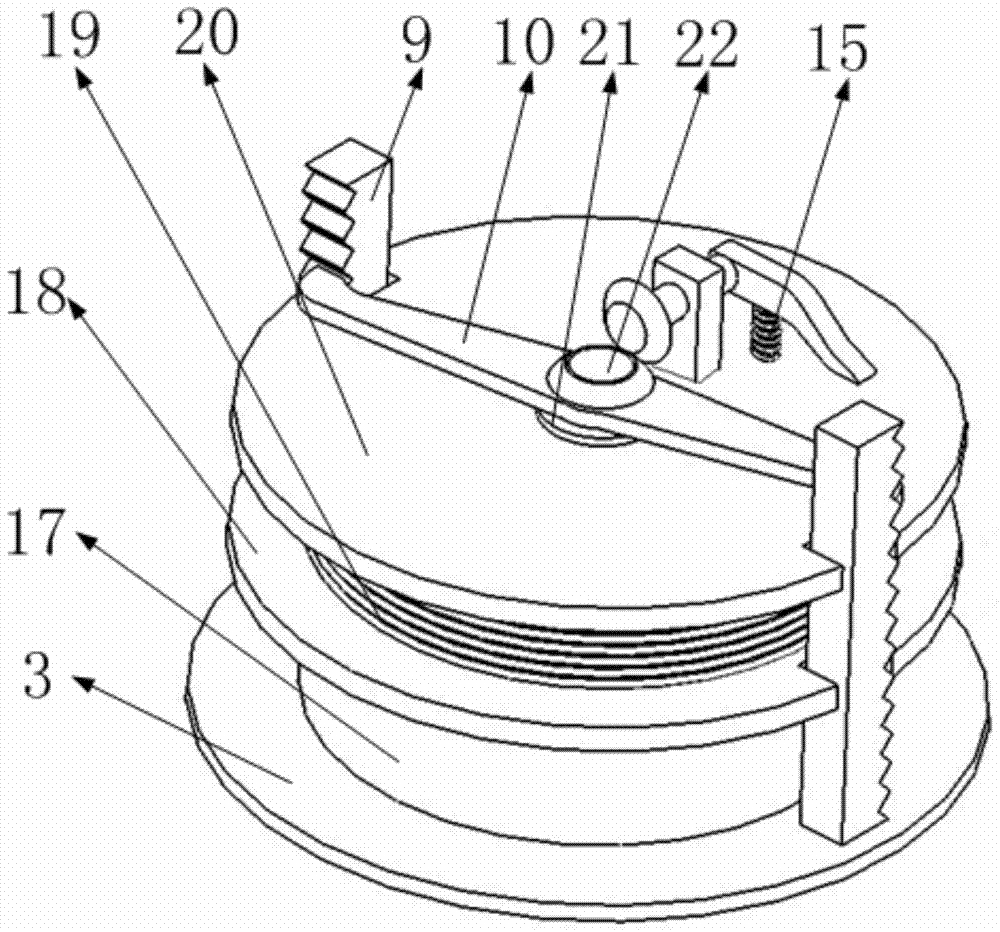

[0047] Such as Figure 19 As shown, it includes the third sub-finger, the second sub-finger, the first sub-finger, the palm plate, the main finger, the power unit combination fixed plate, the power unit combination, the arm sleeve, the power unit combination front cover, and the power unit combination shell , power unit stabilizer, power unit combined back cover, first and second fingers swing block, main finger swing block support, main finger execution unit support, main finger swing block, execution unit lugs, execution unit, power unit, power unit outlet , where as Figure 19 As shown, the second subfinger and the third subfinger are fixedly installed on one side of the palm board in turn, as shown in Figure 23 As shown, the swing block of the first secondary finger is fixedly installed on the first secondary finger, and the swing block of the first secondary finger is installed on the palm plate through a cylindrical pin, as shown in Figure 24 , 25 , 26, the main fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com