A simulated mechanical finger based on electromagnetic drive

A mechanical finger, electromagnetic drive technology, applied in the directions of manipulators, chucks, manufacturing tools, etc., can solve the problems of inaccurate positioning of mechanical fingers, increased equipment weight, virtual swing of fingers, etc., to achieve convenient layout, good practical prospects, and simplification effect of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

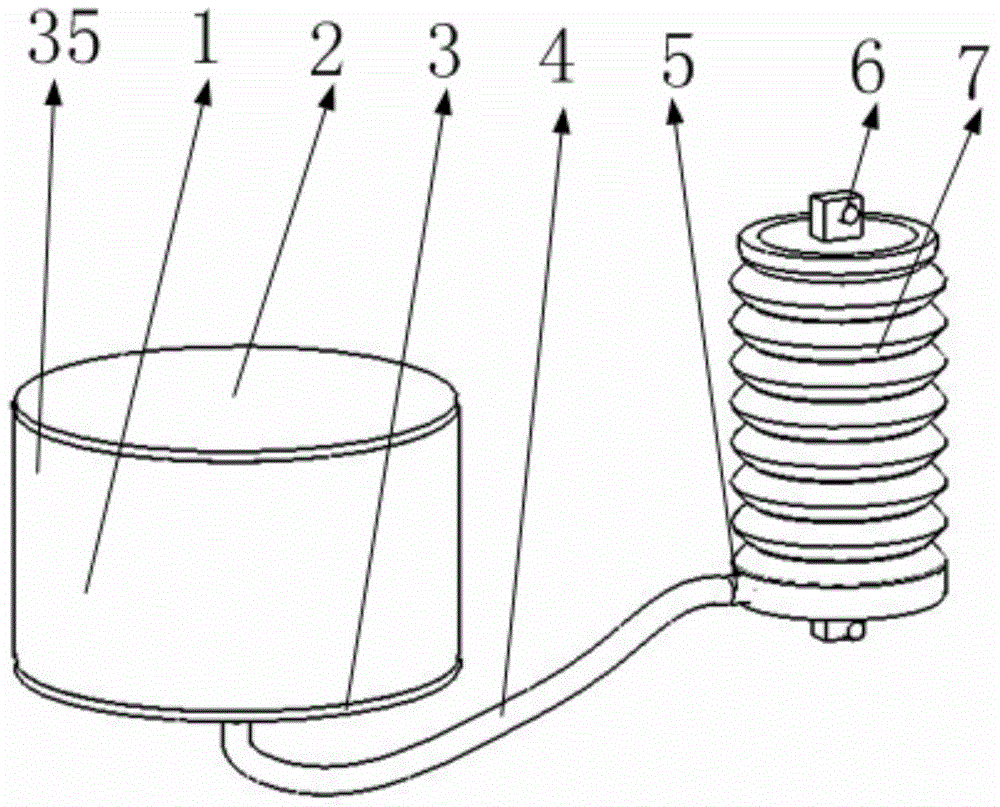

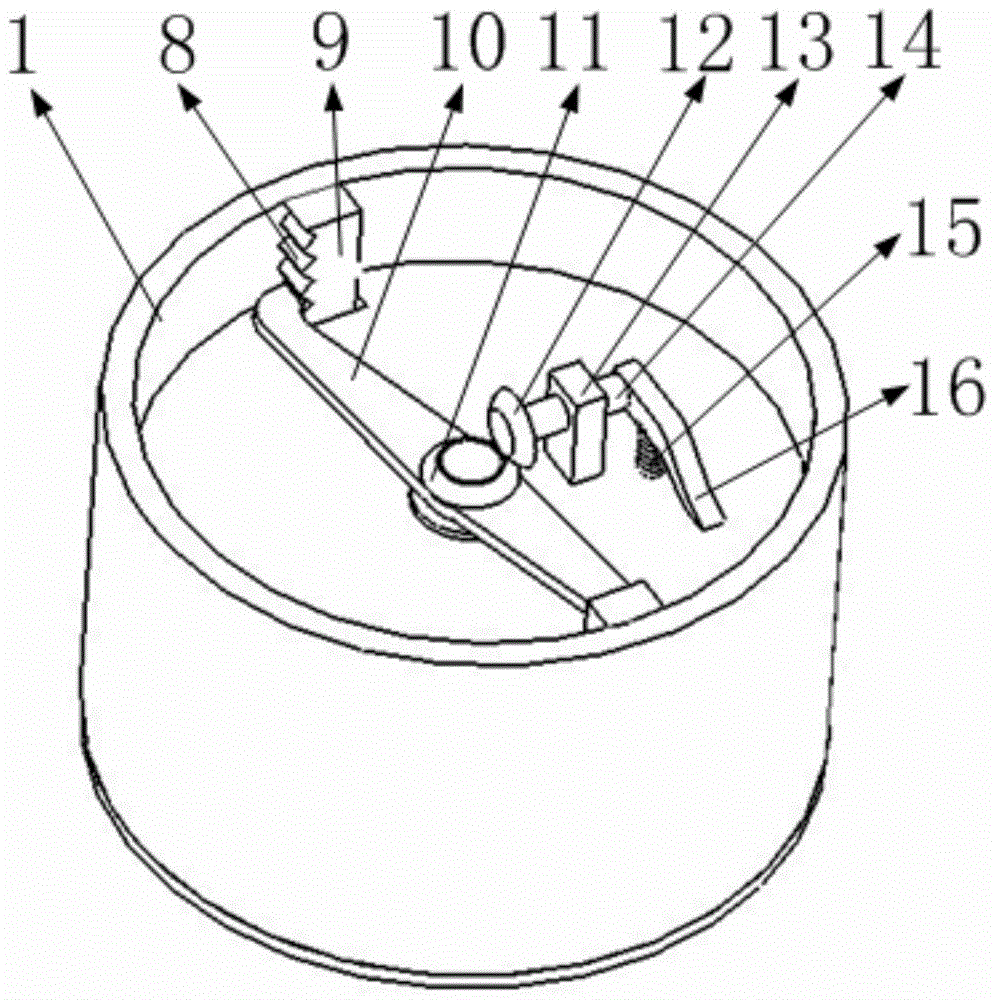

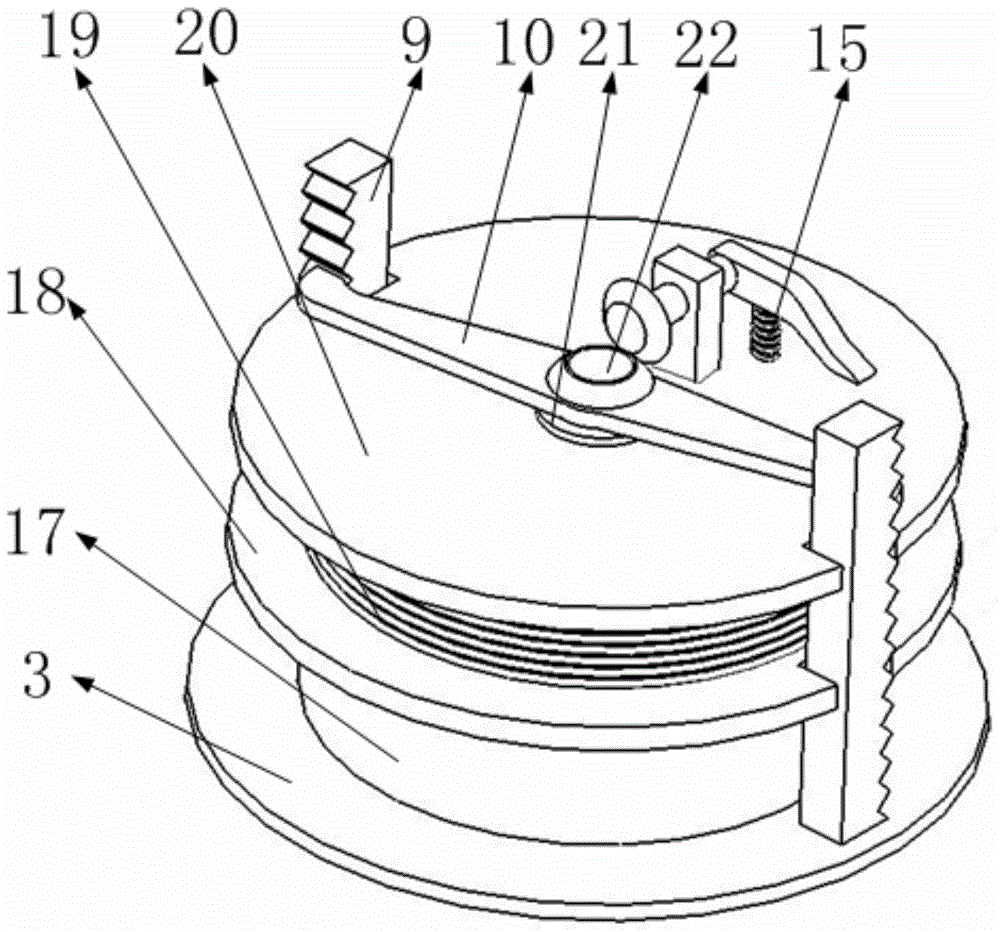

[0036] Such as Figure 15 As shown, it includes the fourth bracket of the mechanical finger, the third bracket of the mechanical finger, the second bracket of the mechanical finger, the first bracket of the mechanical finger, the support of the execution unit, the limit plate of the mechanical finger bracket, the third return spring of the mechanical finger, the second mechanical finger Two return springs, the first return spring of the mechanical finger, the support of the return spring of the mechanical finger, the lug of the execution unit, the power unit, the execution unit, and the liquid medium conduit, such as Figure 16 As shown, the second bracket of the mechanical finger is installed on the first bracket of the mechanical finger through a cylindrical pin, the third bracket of the mechanical finger is installed on the second bracket of the mechanical finger through a cylindrical pin, and the fourth bracket of the mechanical finger is installed on the second bracket of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com