LED UV printing and curing device

A curing device, LED lamp technology, applied in printing, printing machines, general parts of printing machinery, etc., can solve problems such as reduced work efficiency, operator physical injury, air pollution, etc., to improve curing speed, reduce air pollution, The effect of purifying the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

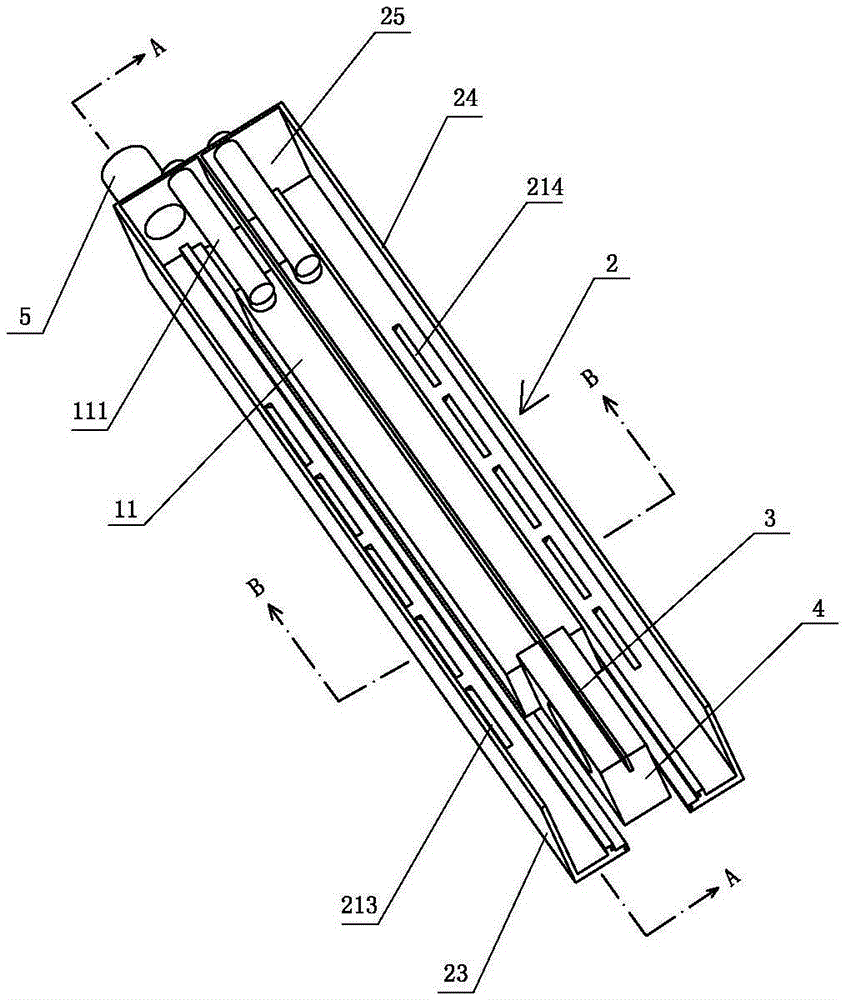

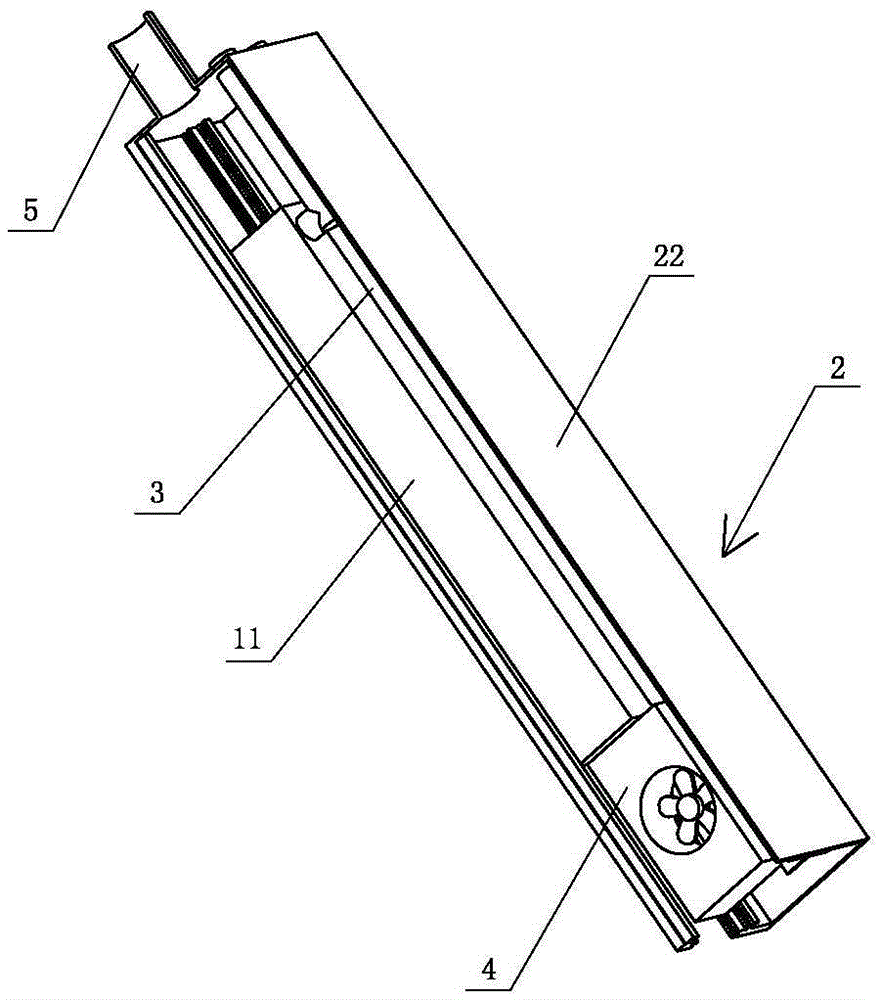

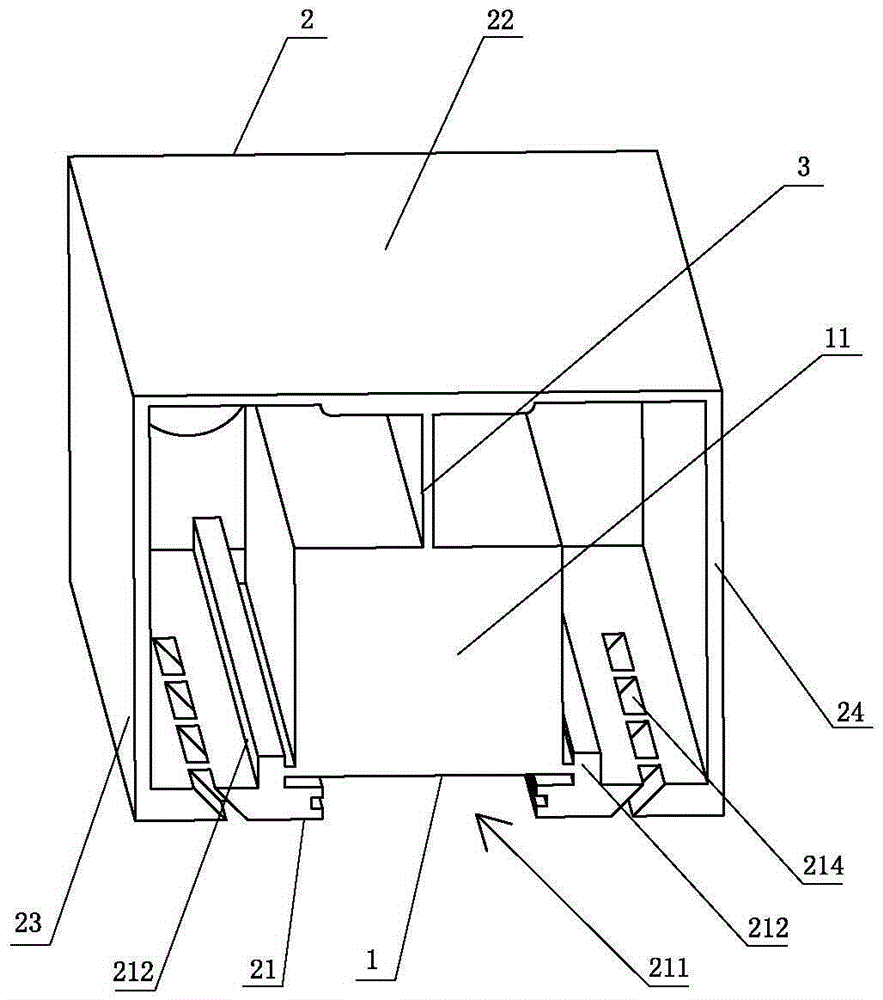

[0023] Such as figure 1 , 2 As shown in . It has a longitudinal opening 211, and both sides of the longitudinal opening 211 and the bottom wall 21 of the housing 2 are provided with longitudinal locking grooves 212, and the two sides of the LED lamp chip substrate 1 are locked in the longitudinal locking grooves 212 and can move forward and backward; In this way, it is convenient for the maintenance and maintenance of the LED lamp grain substrate 1 and its cooling device 11;

[0024] Between the top of the cooling device 11 of the LED lamp chip substrate 1 and the top wall 22 of the housing 2, a partition 3 is installed longitudinally. The partition 3 divides the inner cavity of the housing 2 into left and right parts. The air suction chamber and the right part are air injection chambers; two rows of ventilation holes are respectively opened on the bottom wall 21 of the housing on both sides of the LED lamp grain substrate 1, that is, the bottom wall 21 of the suction chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com