Bismuth ferrite-based thin film containing doping elements, and preparation method thereof

A bismuth ferrite-based, doped element technology, applied in coatings and other directions, can solve the problems of poor performance and complex manufacturing process of piezoelectric ceramics, and achieve the effect of beneficial ferroelectric properties and large lattice distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The invention also discloses a preparation method of a bismuth ferrite-based thin film containing doping elements, comprising the following steps:

[0039] Step 1: heating and stirring bismuth nitrate, iron nitrate and nitrates of Group IIIA metal elements, dissolving them in acetic acid, and then adding acetylacetone to obtain a precursor solution;

[0040] The molar ratio of the iron ion and the metal element of group IIIA is (1-x):x;

[0041] The ratio of the molar weight of described bismuth ion to the total molar weight of iron ion and gallium ion is 1:1;

[0042] Step 2: coating the precursor solution on the substrate, heating and drying, and annealing to obtain a bismuth ferrite-based thin film containing doping elements having an atomic ratio as shown in formula I;

[0043] BiFe 1-x A x o 3 (I);

[0044] Wherein, A is a metal element of group IIIA; x is 0.1-0.3.

[0045] According to the present invention, at first bismuth nitrate, ferric nitrate and the n...

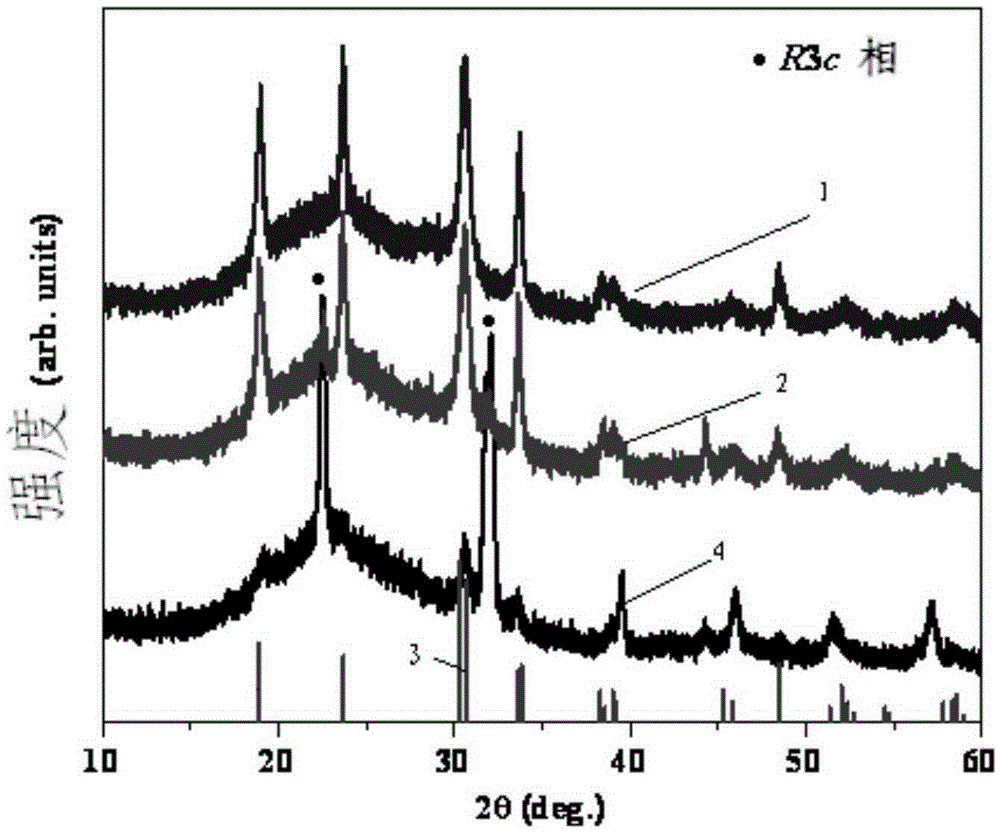

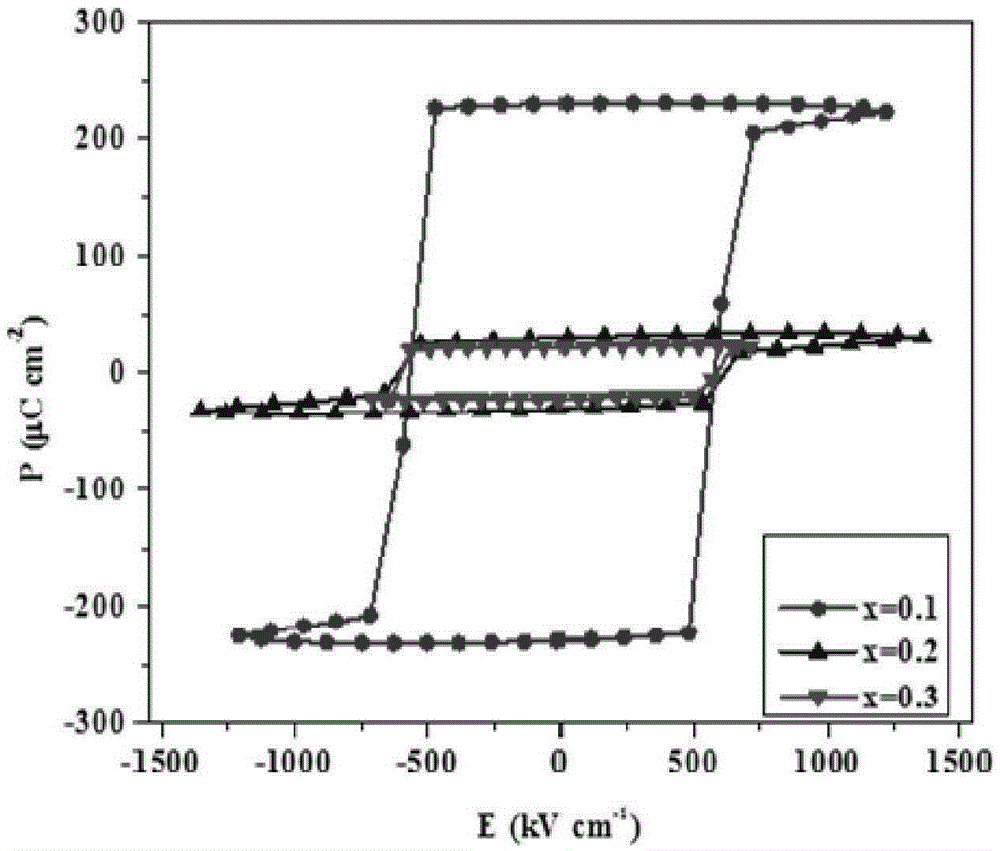

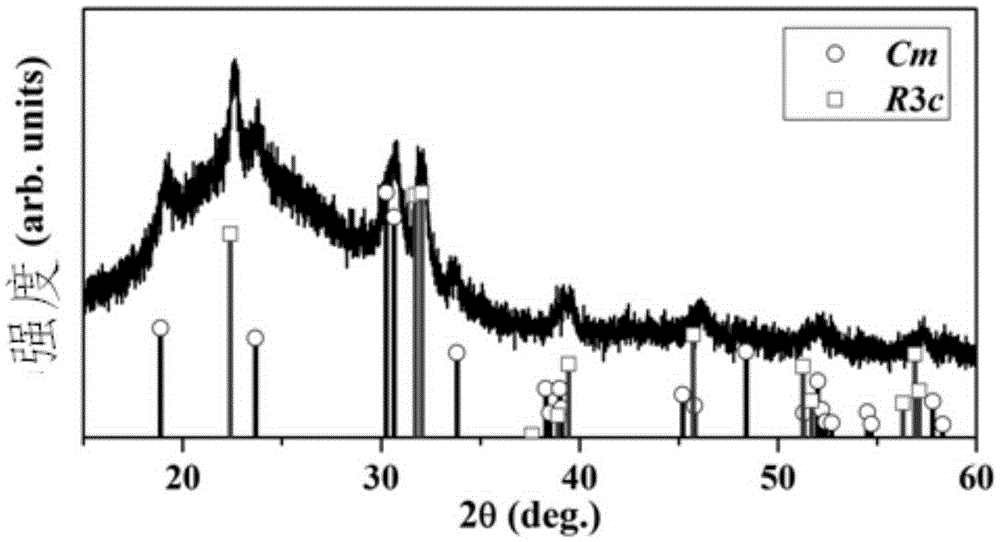

Embodiment 1

[0058] Bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O, 99.5%), iron nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O, 99.5%) and gallium nitrate octahydrate (Ga(NO 3 ) 3 ·8H 2 O, 99.5%). The molar ratio of Bi, Fe and Ga is 1:0.9:0.1. Under heating and stirring, dissolve in acetic acid (C 2 h 4 o 2 , 99.7%). Add acetylacetone (C 5 h 8 o 2 , 99%) to form a precursor solution, the metal ion concentration of the precursor solution is 0.2mol / L.

[0059] The precursor solution was coated onto the glass substrate by spin-coating method. On the 180°C and 380°C heating plates, hold for 180s each to evaporate the solvent and pyrolyze the organics. To achieve the desired film thickness (approximately 200 nm), the spin-coating and heating process was repeated 5 times. Afterwards, it was annealed at 500°C for 5 hours in an annealing furnace to obtain a crystalline thin film BiFe 0.9 Ga 0.1 o 3 .

Embodiment 2

[0061] Bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O, 99.5%), iron nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O, 99.5%) and gallium nitrate octahydrate (Ga(NO 3 ) 3 ·8H 2 O, 99.5%). The molar ratio of Bi, Fe and Ga is 1:0.8:0.2. Under heating and stirring, dissolve in acetic acid (C 2 h 4 o 2 , 99.7%). Add acetylacetone (C 5 h 8 o 2 , 99%) to form a precursor solution, the metal ion concentration of the precursor solution is 0.2mol / L.

[0062] The precursor solution was coated onto the glass substrate by spin-coating method. On the heating plate at 190°C and 400°C, hold for 180s each to evaporate the solvent and pyrolyze the organic matter. To achieve the desired film thickness (approximately 200 nm), the spin-coating and heating process was repeated 4 times. Afterwards, it was annealed at 510°C for 5 hours in an annealing furnace to obtain a crystalline thin film BiFe 0.8 Ga 0.2 o 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Remanent polarization | aaaaa | aaaaa |

| Remanent polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com