Weaving equipment weaving dust collection device

A technology for textile equipment and textile dust is applied in the field of textile dust collection devices for textile equipment, which can solve the problems of dense textile dust, physical health impact, and impact on workshop cleanliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

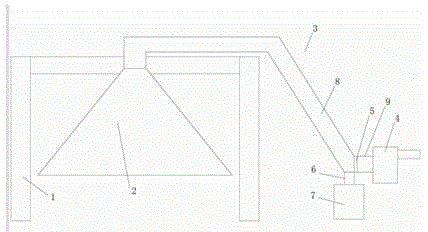

[0007] as attached figure 1 Shown, the present invention is made up of support 1, collection bucket 2, collection pipe 3, fan 4, filter screen 5, dust outlet pipe 6, collection bag 7, inclined pipe 8 and straight pipe 9. The bracket 1 can be installed on the textile equipment. The bracket 1 is provided with a collection bucket 2 with a conical cross section. The collection bucket 2 is provided with a collection pipe 3 connected to the collection chamber. A filter screen 5 is arranged in the collection pipe 3 , and a dust discharge pipe 6 is provided at the front end of the filter screen 5 , and the outlet end of the dust discharge pipe 6 is in the collection bag 7 . The collecting pipe 3 includes an inclined pipe 8 and a straight pipe 9 connected with the inclined pipe, and the filter screen 5 is located at the junction of the straight pipe 9 and the inclined pipe 8 . The straight pipe 9 and the inclined pipe 8 are threaded, which is convenient for the replacement of the filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com