A Steady State Imaging Technology and Azimuth Recognition System for Surrounding Rock Cracks

An identification system, steady state technology, applied in earthwork drilling, wellbore/well components, construction, etc., can solve problems such as the development of borehole fissures, fragmentation degree, unfavorable analysis, probe positioning, etc. that cannot be clearly reflected, and achieve convenient Image processing and analysis, facilitating the acquisition of images, ensuring the effect of real reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

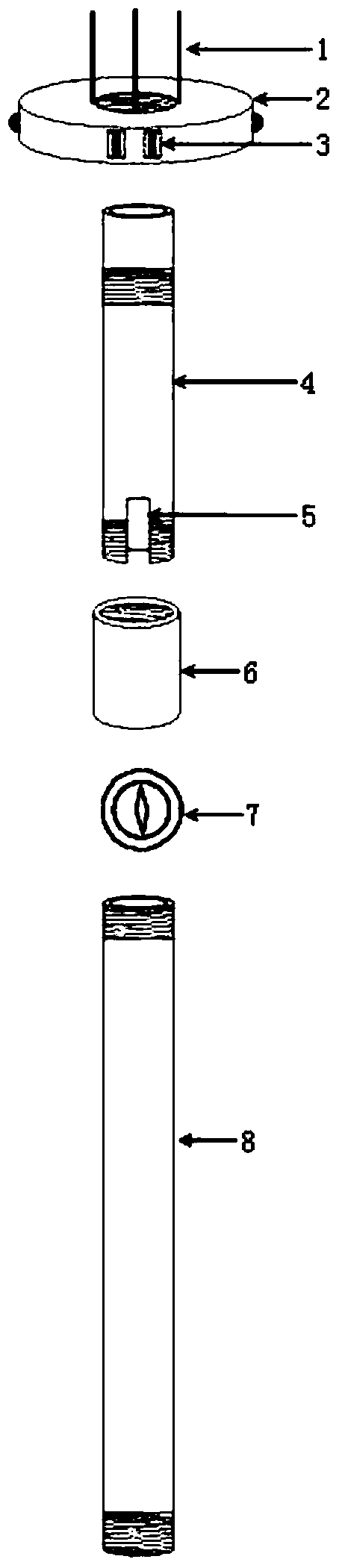

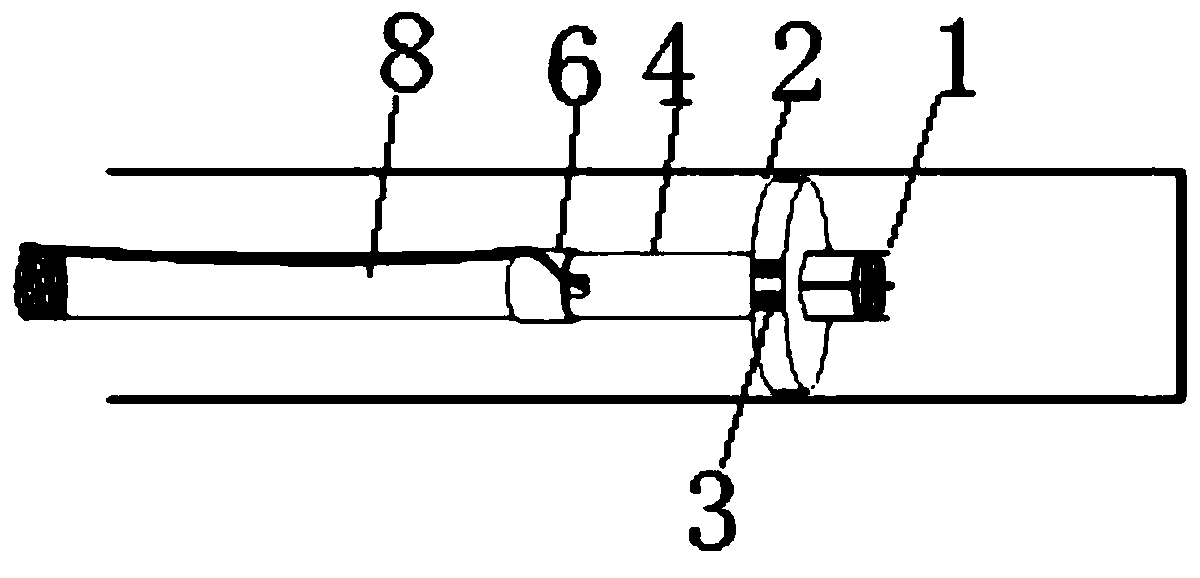

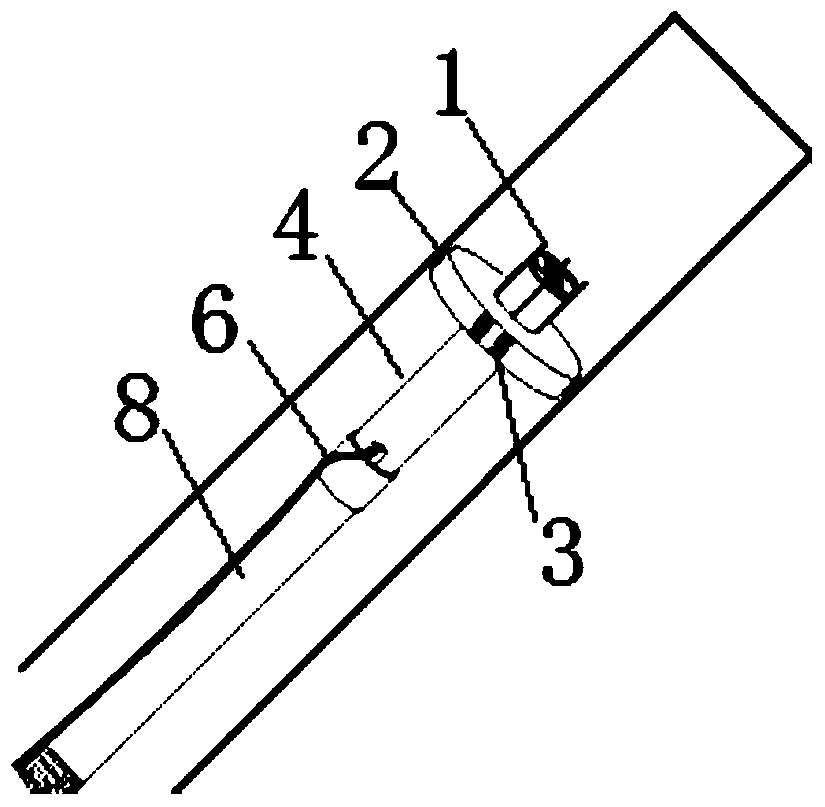

[0026] A steady-state imaging technology for cracks in surrounding rocks and an azimuth recognition system, including an azimuth indicating column 1, a fixed disk 2 in a steady-state imaging hole, a sliding roller 3 on the hole wall, a fixed probe tube 4, a cable outlet 5, and a connector 6 , compass 7, and probe conveying tube 8, the lower part of the probe fixing tube 4 is provided with a cable outlet 5, the upper part of the probe fixing tube 4 is connected to the fixed disc 2 in the steady-state imaging hole, and the fixed disc 2 in the steady-state imaging hole is used For the fixed probe, several hole wall sliding rollers 3 are provided on the outer surface of the fixed disk 2 in the steady-state imaging hole. The hole wall sliding rollers 3 of the present invention are provided with two, and the hole wall sliding rollers 3 are made of rubber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com