A fan damping shaft

A shock absorber shaft and fan technology, applied in liquid fuel engines, machines/engines, mechanical equipment, etc., can solve the problems of shock absorber rubber prolapse damage, inability to locate axially, poor vibration damping effect, etc., to reduce vibration amplitude , to avoid rigid contact, the effect of reasonable mass distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

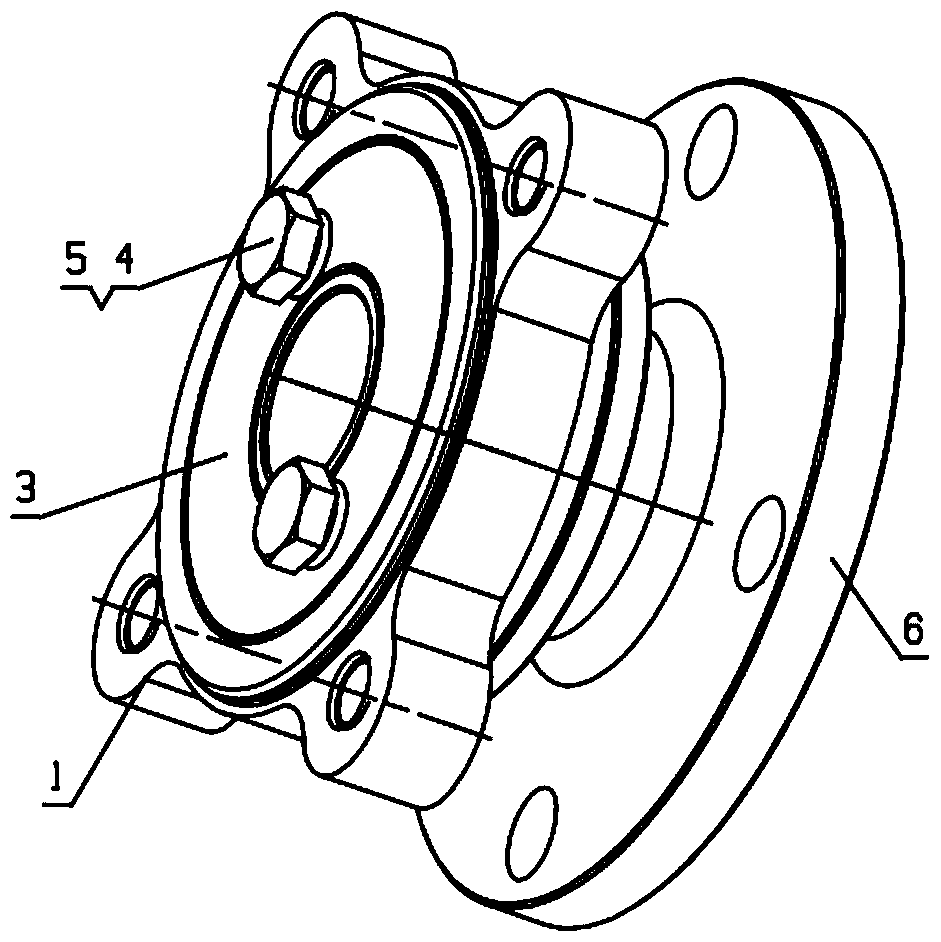

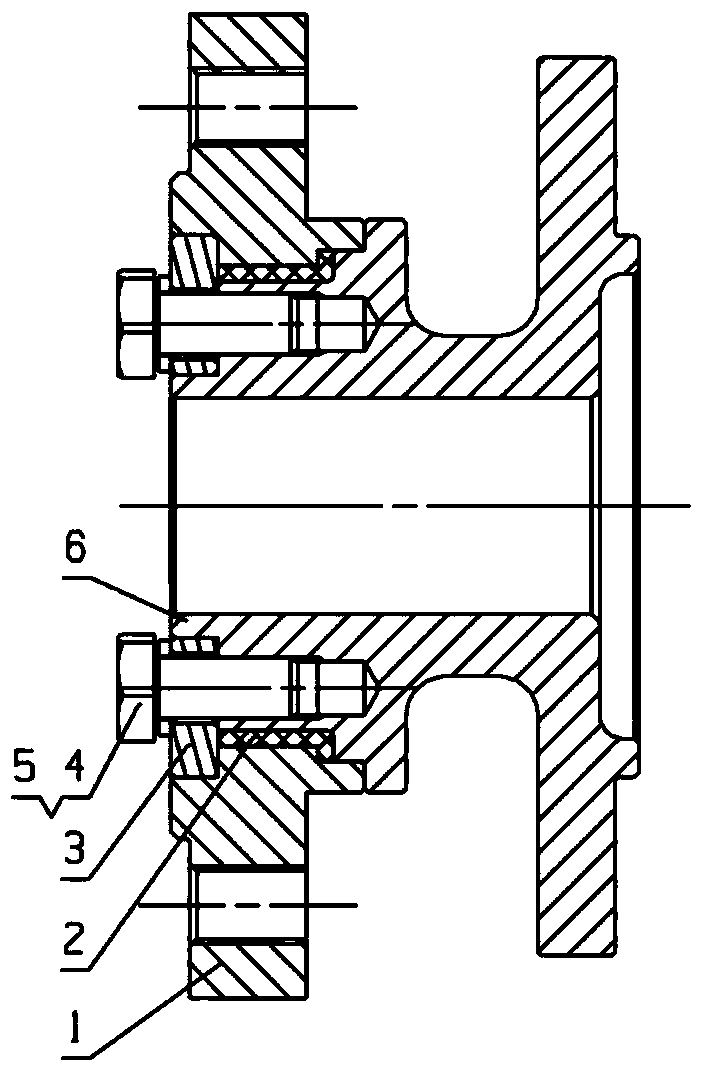

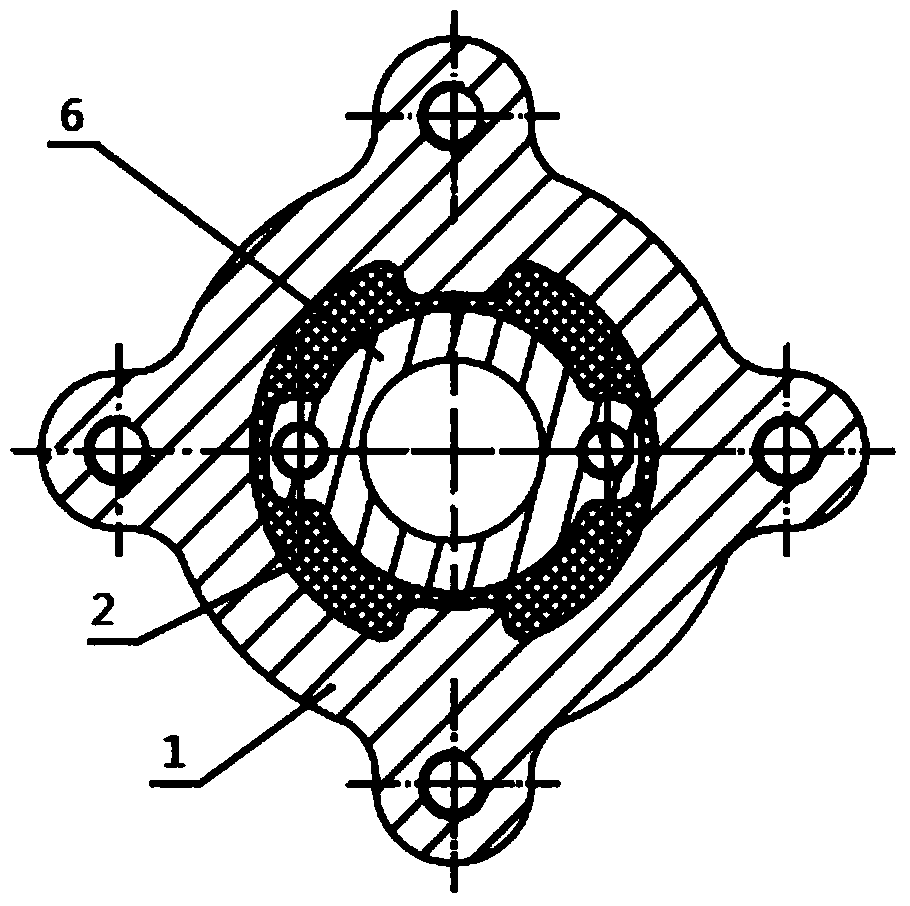

[0031] The specific embodiment of the present invention is as Figure 1 to Figure 6 As shown, it is a fan damping shaft, including a first flange 1 and a second flange 6; the first flange 1 and the second flange 6 are connected by a shaft hole, and there is also a preventive The rubber ring 2 that is rigidly connected between the two is provided with concave-convex matching structures between the first flange 1 and the rubber ring 2, and between the second flange 6 and the rubber ring 2. structure.

[0032] The first flange 1 is provided with a mounting hole, the second flange 6 is provided with a mounting shaft, and the rubber ring 2 is arranged between the mounting hole and the mounting shaft, wherein the rubber ring 2 acts as a shock absorber, which can effectively reduce the engine crankshaft The damage degree of the instantaneous torsional vibration inertia force to the mounting bolts and other parts.

[0033] A shaft shoulder 12 is arranged on the outer end surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com