Oil cylinder tail end automatic lockup valve and hydraulic oil cylinder with oil cylinder tail end automatic lockup valve

An automatic locking and hydraulic cylinder technology, applied in the field of hydraulic cylinders, can solve problems such as poor locking, leakage, and slow movement of hydraulic cylinder piston rods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

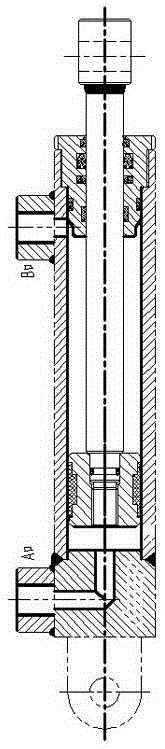

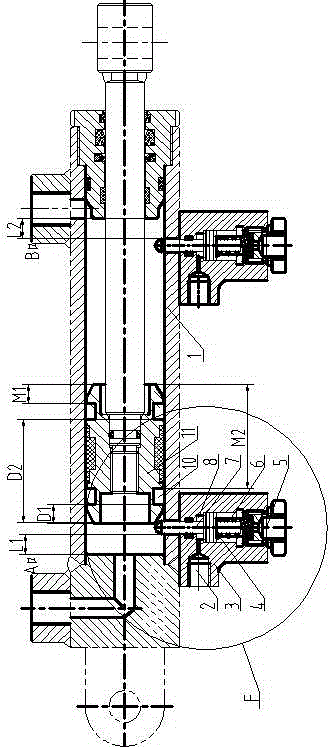

Image

Examples

Embodiment Construction

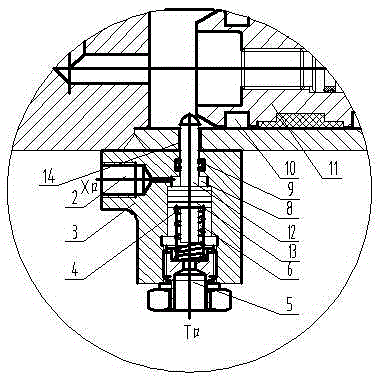

[0020] as shown in the picture image 3 As shown, an automatic locking valve at the end of an oil cylinder includes a valve body 3 installed on the wall of the oil cylinder at the end of the oil cylinder. The valve body is provided with a valve core 7 extending into the oil cylinder. The core plate is installed on the mandrel, and the lower part of the valve core is provided with a spring chamber 6, and the core plate and the spring chamber are connected by a friction pair, and the return spring 4 is set on the mandrel at the lower part of the core plate, and the core plate The length of the lower mandrel is less than the height of the spring cavity at the lower part of the core plate. The bottom of the spring cavity is provided with an oil drain plug 5, and the oil drain plug is threadedly connected with the valve body; a sealing ring 9 is arranged between the valve core and the valve body, and the valve body and the valve core at the bottom of the sealing ring are enclosed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com