Three-dimensional measuring equipment and data fusion calibration method used for the three-dimensional measuring equipment

A technology of three-dimensional measurement and equipment, applied in the field of three-dimensional measurement, can solve the problems of inability to adapt to industrial assembly line production, complex information fusion process, practical convenience and cost compromise, and achieve fully automatic mechanical operation, reduce human labor, and detect fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

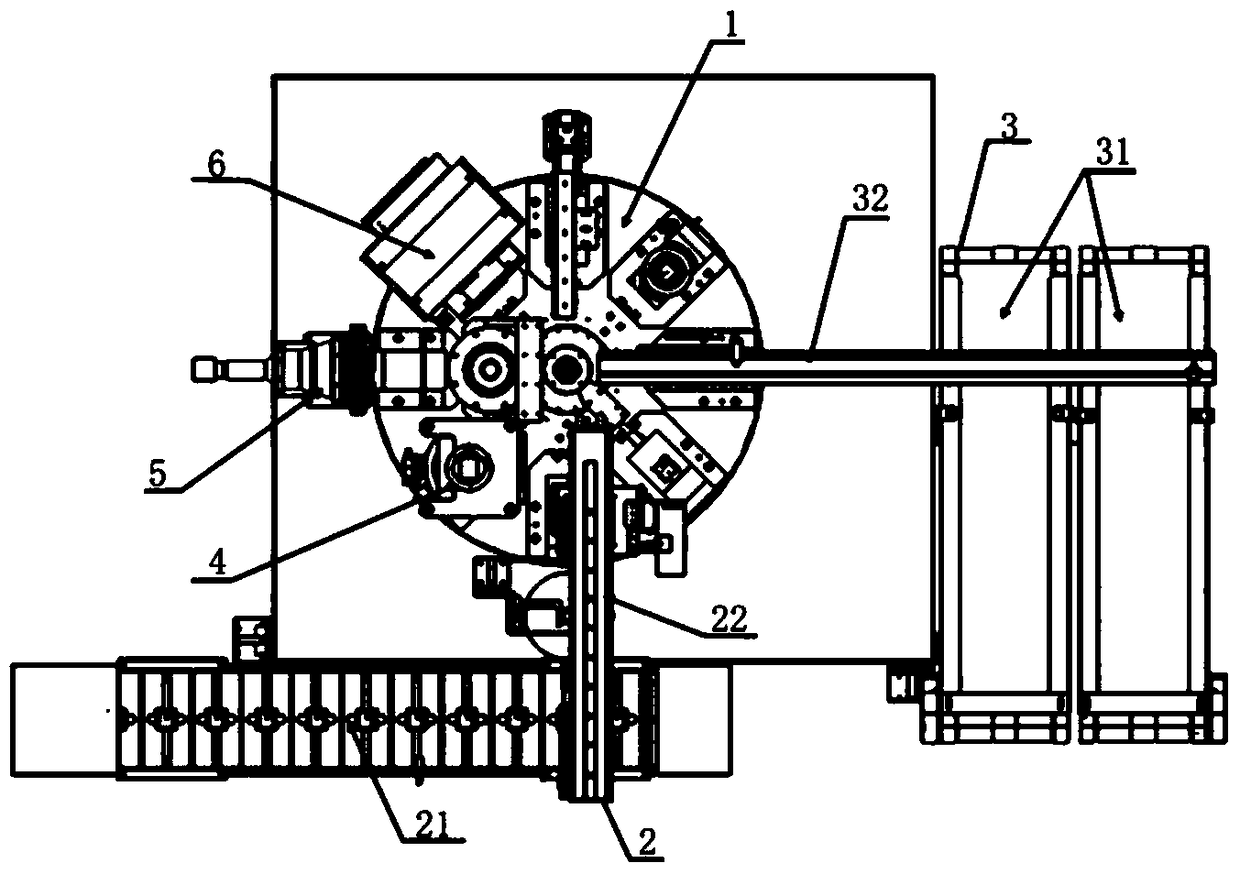

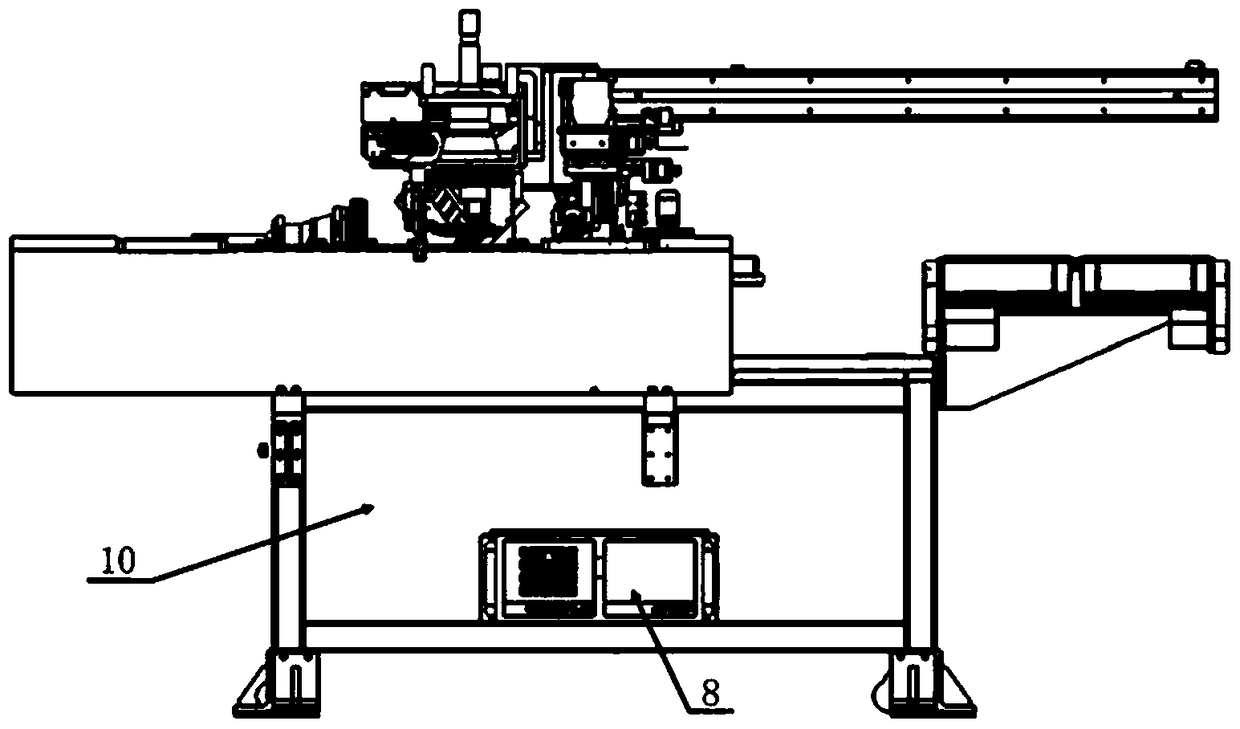

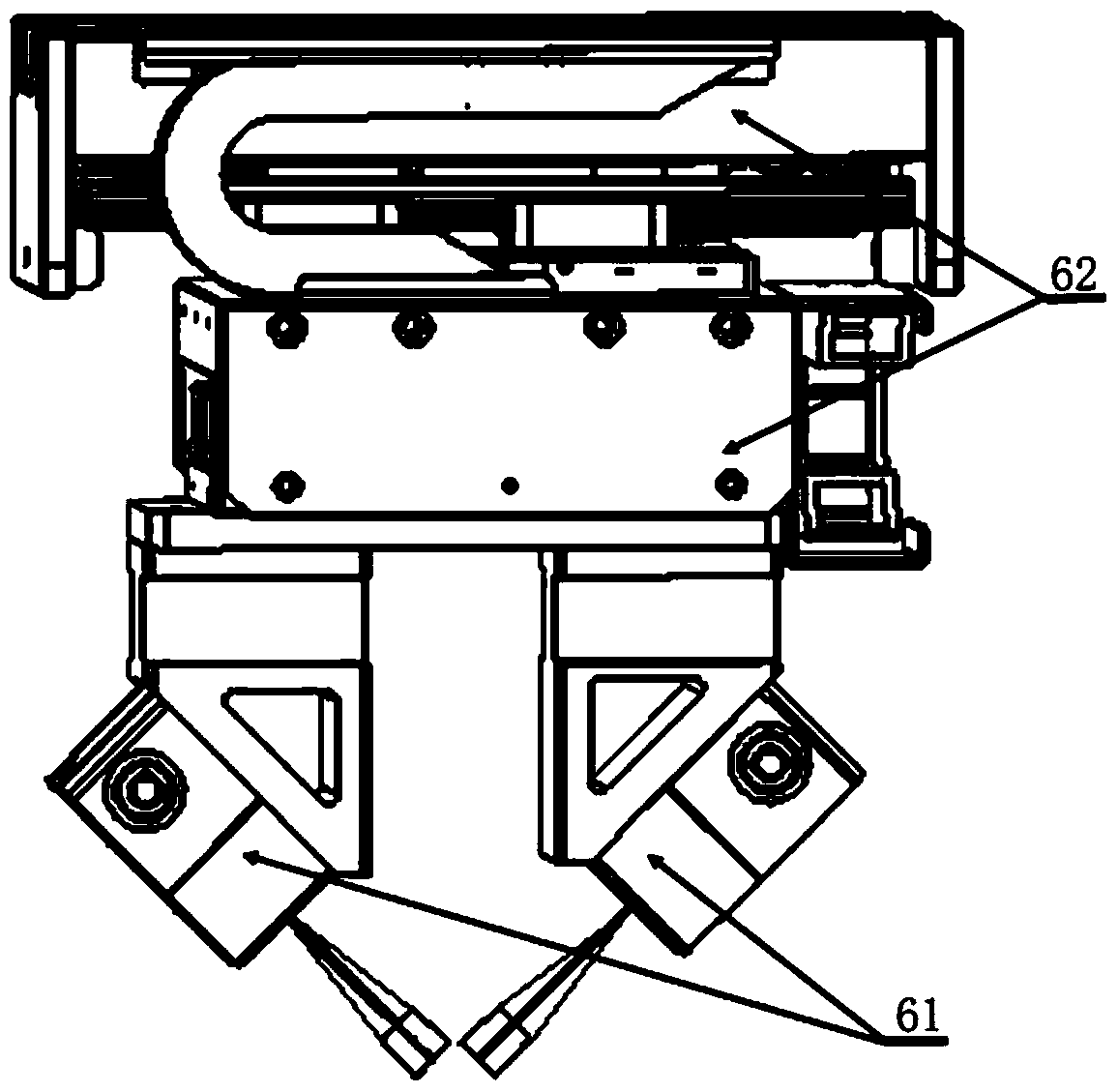

Examples

Embodiment 2

[0062] This embodiment discloses a data fusion calibration method for the three-dimensional measuring device of Embodiment 1, including the following steps:

[0063](1) Utilize a three-coordinate measuring instrument to establish the world coordinate system XYZ on the basis of the calibration block, and record the coordinates of the calibration block features in the world coordinate system XYZ; the calibration block features are wavy side walls, the first square Through hole and the second square through hole; and the process of recording the coordinates of the calibration block feature in the world coordinate system XYZ is: recording the data matrix Axy formed by the apex coordinates of the second square through hole, and recording the highest point of the wavy side curvature The data matrix Bxyz formed with the coordinates of the lowest point records the data matrix Cyz formed by the apex coordinates of the second square through hole;

[0064] (2) Determine the workpiece coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com