Device and method for measuring urban rail vehicle wheel diameter based on multiple sensors

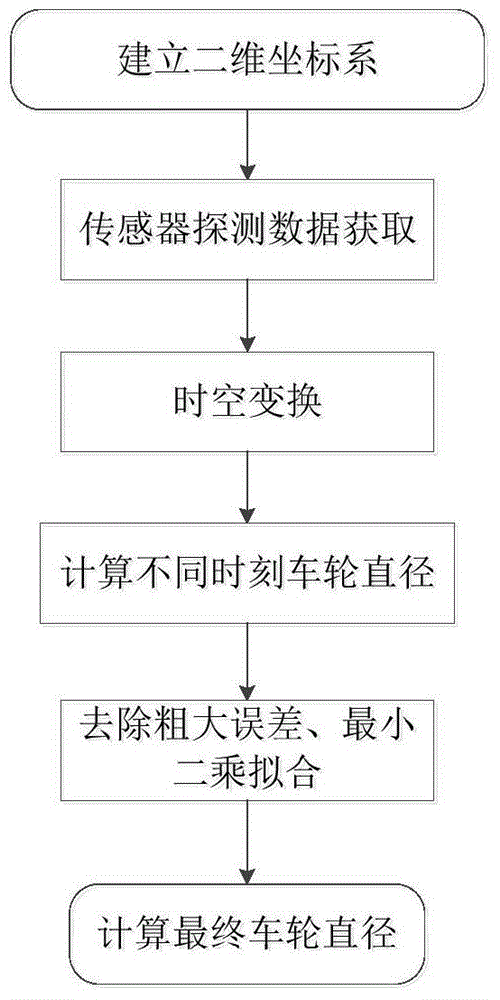

A technology for diameter measurement and urban rail vehicles, applied in measuring devices, electromagnetic measuring devices, electric/magnetic diameter measurement, etc., can solve the problems of complex system structure layout, poor anti-interference ability, high technical difficulty, etc., and achieve high-precision measurement, Easy to operate, simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

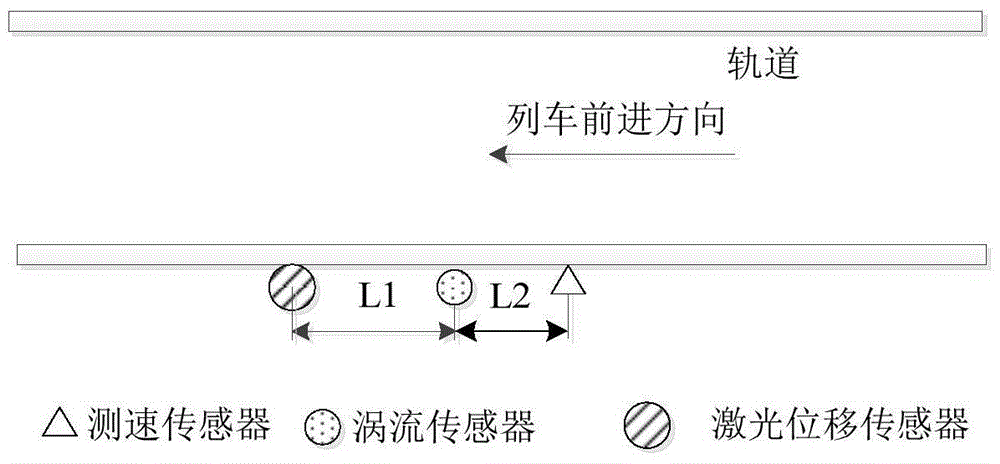

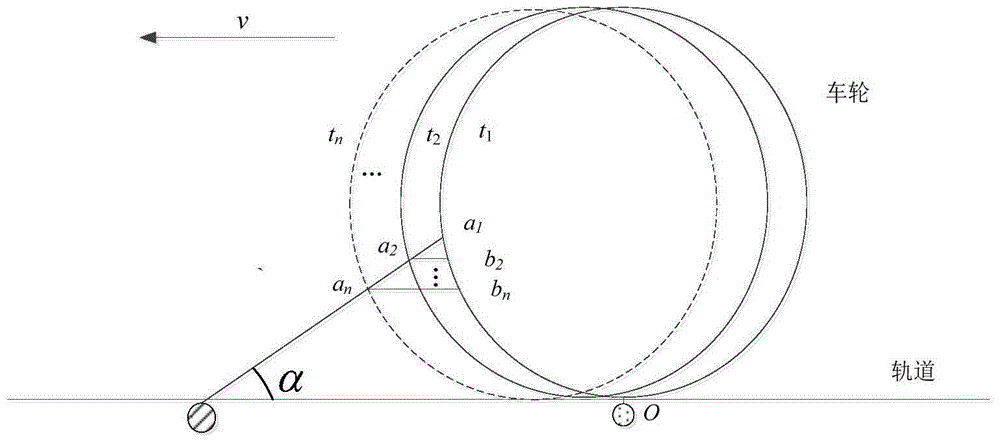

[0053] combine figure 2 , the laser displacement sensor and the track are installed at an angle of 45° beside the track, then α is 45°, the sampling interval of the laser displacement sensor is 20ms, and the installation distance between the laser displacement sensor and the eddy current sensor is L 1 500mm, the installation distance L between the eddy current sensor and the speed sensor 2 is 80mm.

[0054] First record the measured value of the speed sensor as 1.51m / s, and group the detected distance values by time, the wheels pass through the detection system, and the sensor outputs a total of 6 groups (t 1 , t 2 ,...,t 6 ) valid data, as shown in the table below.

[0055]

[0056] The detection value at each moment is transformed in time and space according to the following formula:

[0057] x i = l i ·cosα+vΔt i

[0058] the y i = l i · sinα

[0059] The transformed coordinates are shown in the table below:

[0060]

[0061] Calculate the wheel diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com