Measuring device and method for measuring temperature during aluminum alloy thermoforming process

A measuring device and thermoforming technology, applied in the direction of measuring device, radiation pyrometry, optical radiation measurement, etc., can solve the problems of difficulty and application of infrared temperature measurement, improve production quality and efficiency, eliminate environmental impact, realize The effect of online high-precision measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

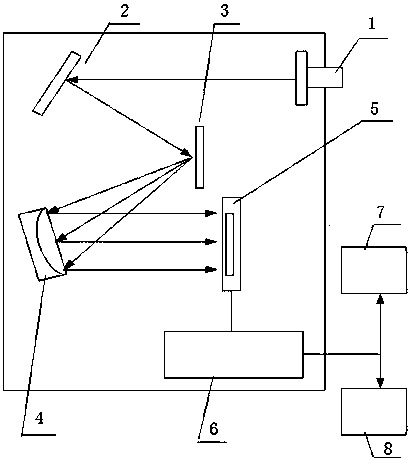

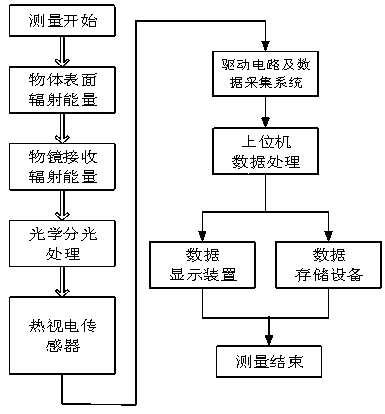

[0018] A temperature measuring device during the thermoforming process of an aluminum alloy according to this embodiment, the measuring device includes an objective lens 1, a collimating objective lens 2, a grating 3, a focusing objective lens 4, a pyroelectric sensor 5, a driving circuit and a data acquisition system 6. LCD display 7, host computer 8; collimating objective lens 2 receives information from objective lens 1, grating 3 receives information from collimating objective lens 2, focusing objective lens 4 receives information from grating 3, and pyroelectric sensor 5 receives information from focusing objective lens 4 , the driving circuit and the data acquisition system 6 receive the information of the pyroelectric sensor 5, and the upper computer 8 and the LCD display 7 receive the information of the driving circuit and the data acquisition system 6;

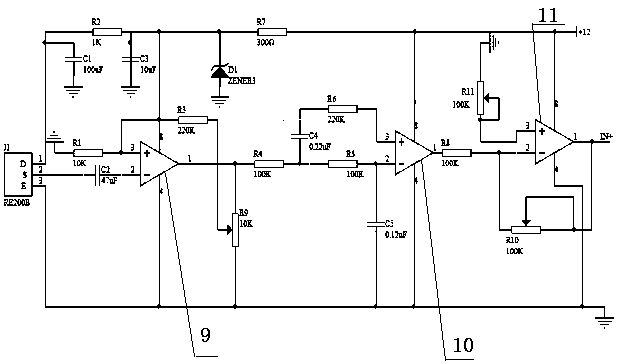

[0019] Moreover, the driving circuit and the data acquisition system 6 include: an amplifier 9, a filter 10, and an ...

specific Embodiment approach 2

[0022] The difference from Embodiment 1 is that the measurement device for the temperature during the hot forming of aluminum alloy in this embodiment further includes a Fresnel optical lens, which is installed on the pyroelectric detection device. On the lens of the detector, the detection sensitivity of the detector is improved to increase the detection distance. The Fresnel lens is made of transparent plastic, and the upper and lower parts of the lens are divided into several equal parts to make a special optical system. The lens, which cooperates with the amplification circuit, can amplify the signal by more than 70 decibels, so that the actions of people within the range of 10 to 20 meters can be measured. The Fresnel lens uses the special optical principle of the lens to produce an alternating "blind area" and "high-sensitivity area" in front of the detector to improve its detection and reception sensitivity. When the object under test passes in front of the lens, the em...

specific Embodiment approach 3

[0023] The difference from Embodiment 2 is that in this embodiment, a temperature measuring device during the hot forming process of aluminum alloy, the pyroelectric sensor 5 is a RE200B dual-element pyroelectric sensor 5, and the sensitive element area of this sensor is 2.0×1.0mm2, substrate thickness 0.5mm, working wavelength 7-14μm, average transmittance>75%, output signal>2.5V (420°k black body 1Hz modulation frequency 0.3-3.0Hz bandwidth 72.5db gain), noise< 200mV(mVp-p) (25℃), balance degree<20%, working voltage 2.2-15V, working current 8.5-24μA(VD=10V, Rs=47kΩ, 25℃), source voltage 0.4-1.1V(VD =10V, Rs=47kΩ, 25°C), operating temperature -20°C- +70°C, storage temperature -35°C- +80°C, field of view 139°×126°. Moreover, the complementary method of dual sensitive elements can effectively suppress the interference caused by temperature fluctuation and vibration temperature change, improve the working stability of the sensor, and its various indexes are relatively good. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com