Dam interior inertial navigation monitoring device automatic traction system

A monitoring device and traction system technology, which is applied in measurement devices, surveying and navigation, height/level measurement, etc., can solve the problems of rough traction mode, difficult positioning of monitoring vehicles, and difficult fixed-point measurement of key parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

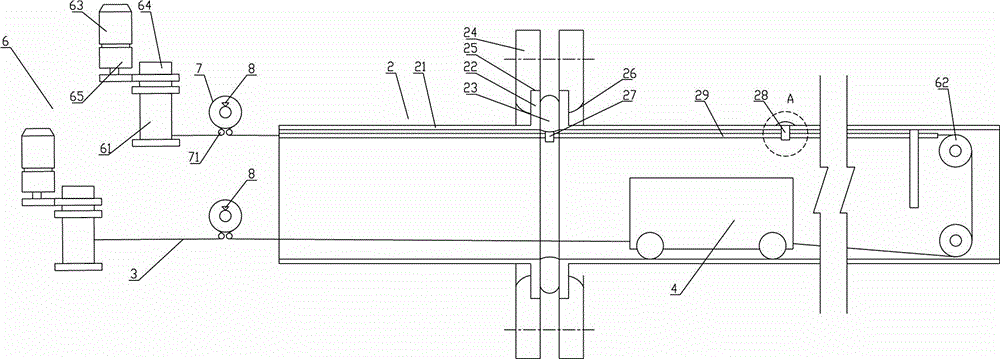

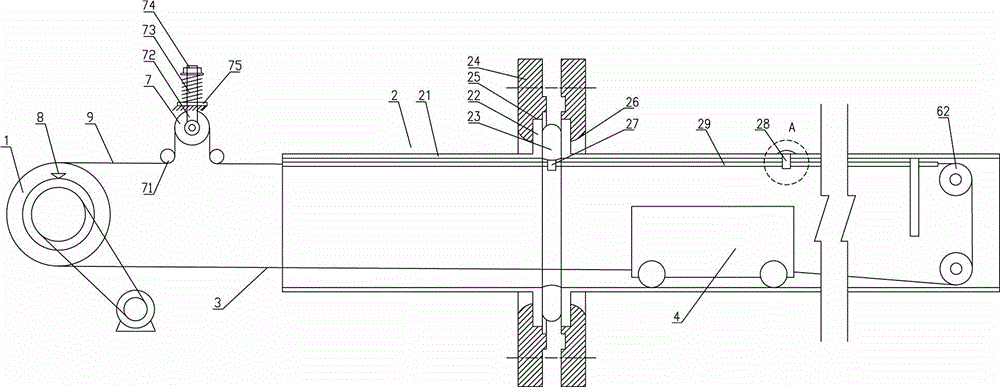

[0037] An automatic traction system for a dam internal inertial navigation monitoring device, comprising a traction device 6, a hoisting device driven by a driving device to rotate is arranged in the traction device 6, a traction rope 3 bypasses the hoisting device, and the traction rope 3 is connected with the hoisting device along the The monitoring device 4 that the flexible detection tube 2 travels is connected;

[0038] Also comprise rotatable first guide wheel 7, traction rope 3 walks around first guide wheel 7, is provided with wrapping angle guide wheel 71 at the front and back of first guide wheel 7, to increase traction rope 3 in the first guide The wrap angle on the wheel 7, in this example, the wrap angle of the traction rope 3 on the first guide wheel 7 is greater than 180 °, thus the structure prevents the traction rope 3 from slipping on the first guide wheel 7, ensuring that the traction rope 3 Keep synchronization between the movement of the first guide wheel ...

Embodiment 2

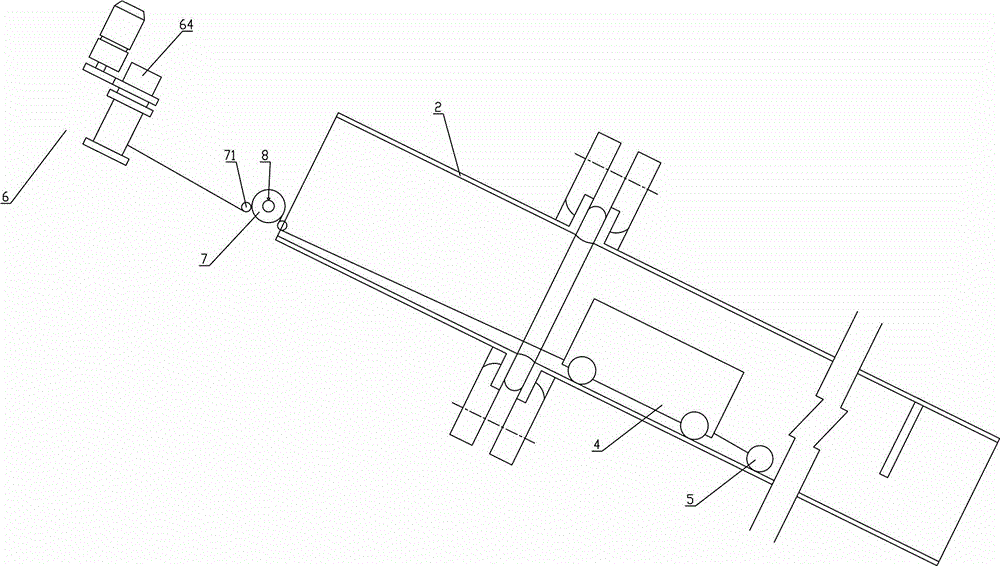

[0041] The preferred solution is as figure 1 Among them, on the basis of Embodiment 1, the flexible detection tube 2 is arranged obliquely, the hoisting device is a reel 61 driven to rotate by the driving device, and the traction rope 3 is connected to the tail of the monitoring device 4. The head of the monitoring device 4 is connected with a weight 5 . The specific structure of the hoisting device is as follows: the servo motor 63 is connected with the reel 61 through a reducer 65, and the reducer includes a worm gear reducer, a gear reducer and a belt reducer, and one or more combinations thereof can be selected. Preferably, a damper 64 is also provided on the shaft of the reel 61 or the reducer, and a magnetic powder damper is selected in this example. When in use, the monitoring device 4 slides down along the flexible detection tube 2 by the weight of the weight 5 of about 5 kg and the weight of the monitoring device 4 itself, the traction rope 3 drives the first guide w...

Embodiment 3

[0043] On the basis of Example 1, such as figure 2 Among them, the hoisting device is a reel 61 driven to rotate by a driving device. The specific structure of the hoisting device is: the servo motor 63 is connected to the reel 61 through a reducer 65, and the reducer includes a worm gear reducer, a gear reducer and One or more combinations of belt reducers can be selected. Preferably, a damper 64 is also provided on the shaft of the reel 61 or the reducer, and a magnetic powder damper is selected in this example.

[0044] There are two groups of hoisting devices, the traction rope 3 of one group of hoisting devices is connected to the tail of the monitoring device 4, and the traction rope 3 of the other group of hoisting devices bypasses the tube bottom guide wheel 62 at the bottom of the flexible detection tube 2 Connect with the head of the monitoring device 4. In a preferred solution, the first guide wheels 7 are correspondingly divided into two groups, so as to obtain mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com