Machine vision technology based leather detection device and detection method

A technology of machine vision and detection device, applied in measuring devices, optical devices, instruments, etc., can solve the problems of short service life of fluorescent tubes, affecting leather production efficiency, short replacement cycle, etc., to achieve stable and reliable lighting and long service life , the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

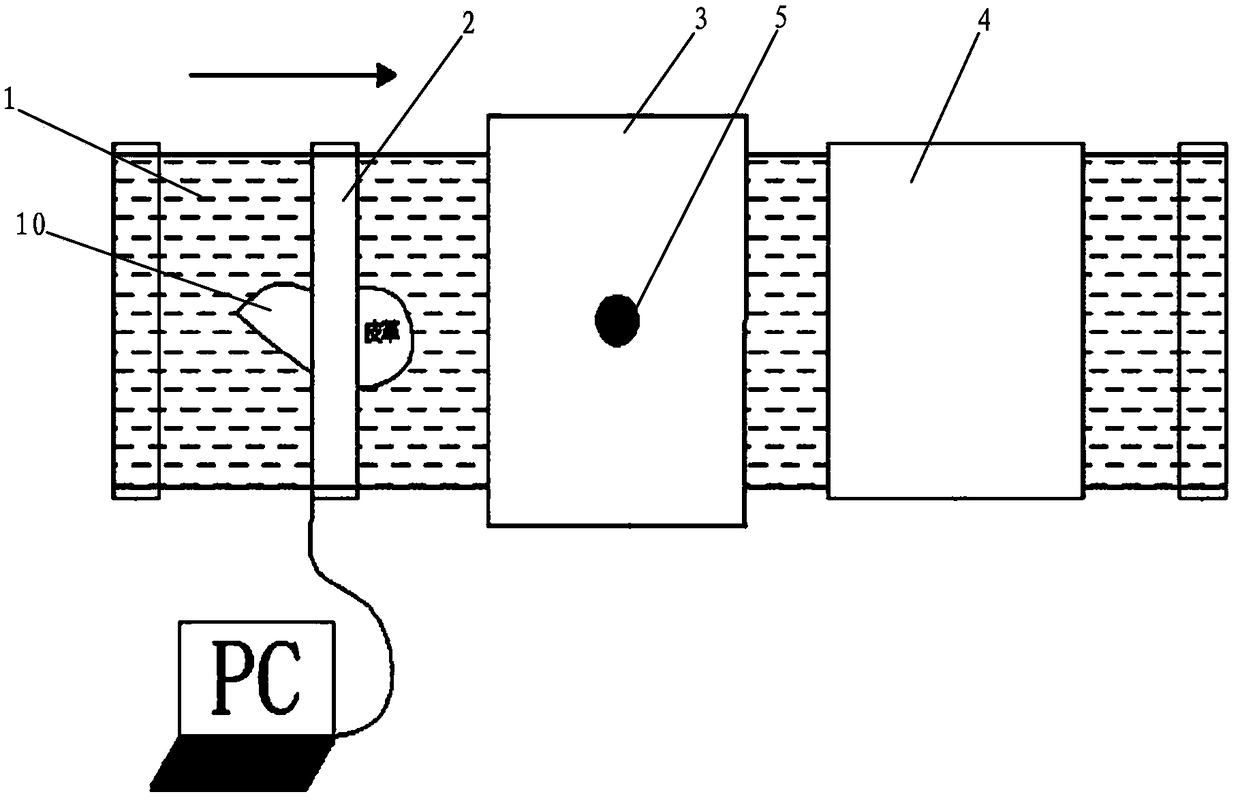

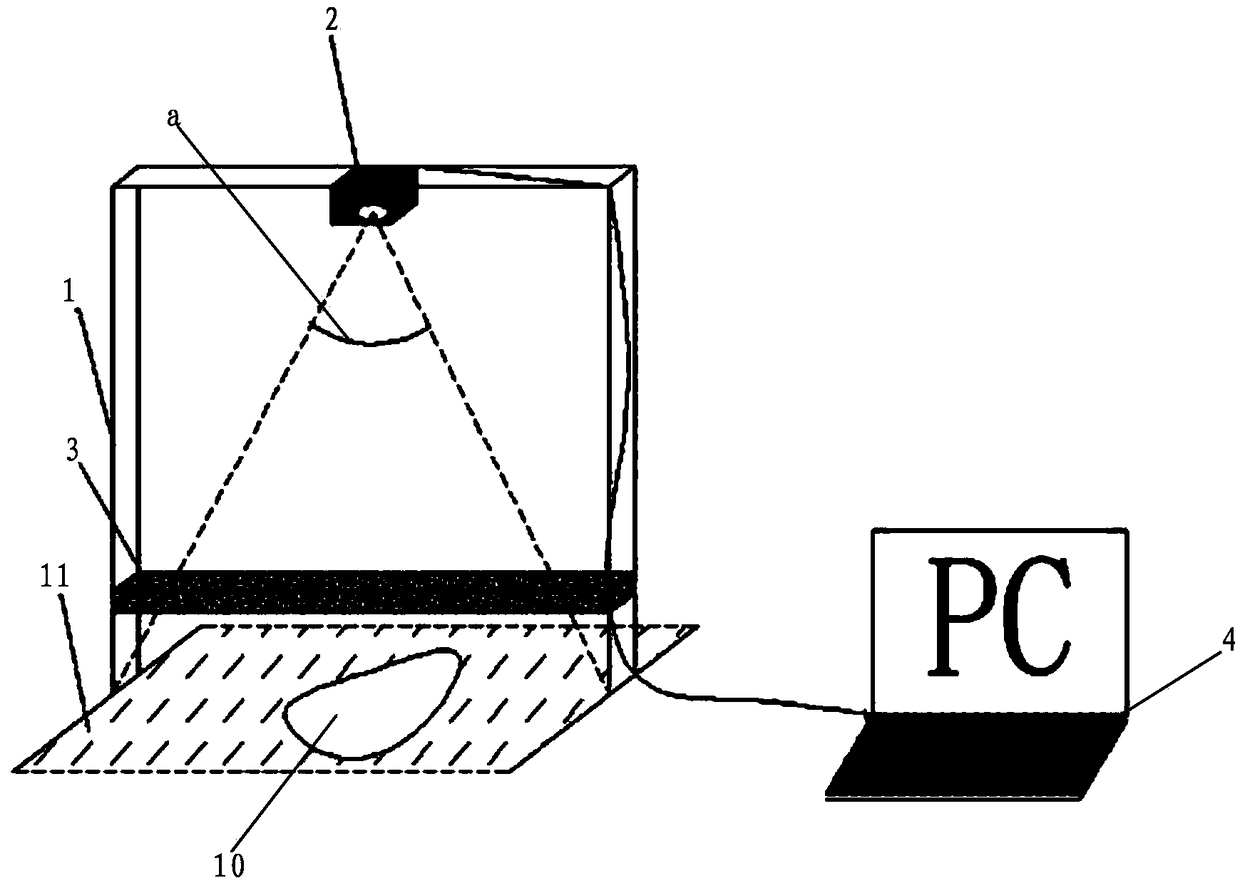

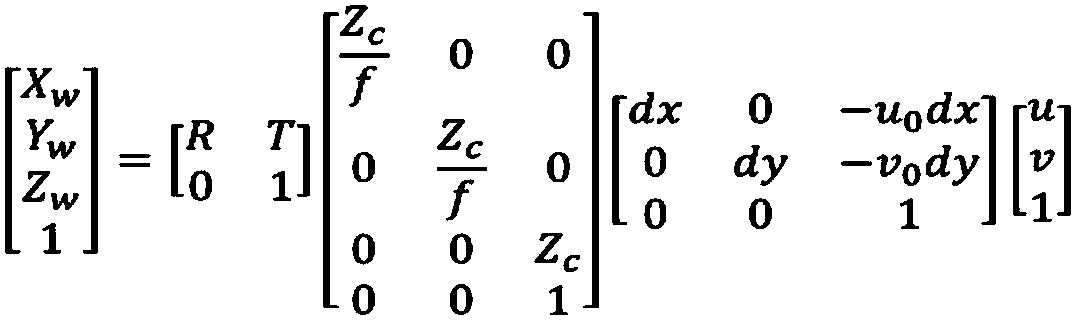

[0038] see figure 2 , this embodiment relates to a leather detection device, including a bracket 1, an industrial camera 2, an LED lamp 3 and a control device 4, the bracket 1 is arranged at the front end of the spray room, and the industrial camera 2 and the LED lamp 3 are fixedly installed On the bracket 1, and the industrial camera 2 and the LED lamp 3 are arranged above the conveyor belt, and the industrial camera 2 is arranged above the LED lamp 3; the leather 10 is placed on the conveyor belt 11, and the industrial camera 2 is placed on the conveyor belt 11 The leather 10 is photographed to obtain the area or position information of the leather 10, and the LED lamp 3 illuminates the leather 10 on the conveyor belt 11 to provide light for the photographing of the industrial camera 2; the control device 4 is electrically connected to the industrial camera 2 , the control device 4 takes photos of the leather 10 on the conveyor belt 11 through the industrial camera 2 to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com