Bidirectional-loading double-turning water-lubrication thrust bearing testing apparatus with pretightening force

A thrust bearing and two-way loading technology, which is applied in mechanical bearing testing and other directions, can solve problems such as high risk and inability to adjust working conditions, and achieve the effect of simple installation process, simple installation and debugging, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

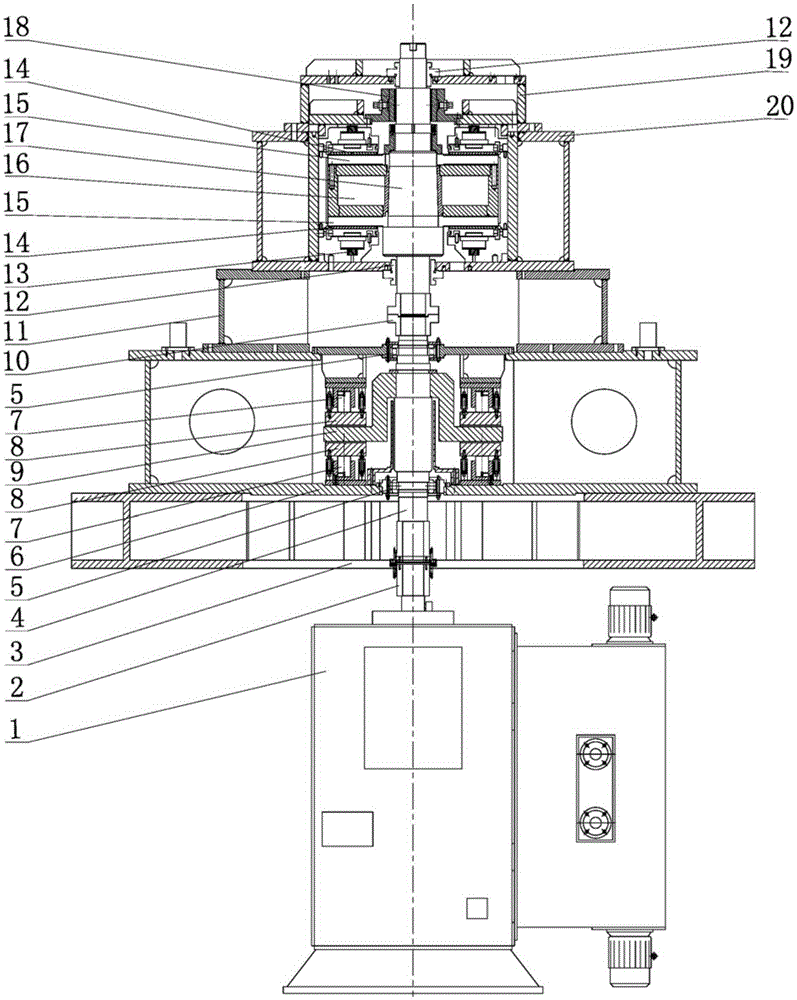

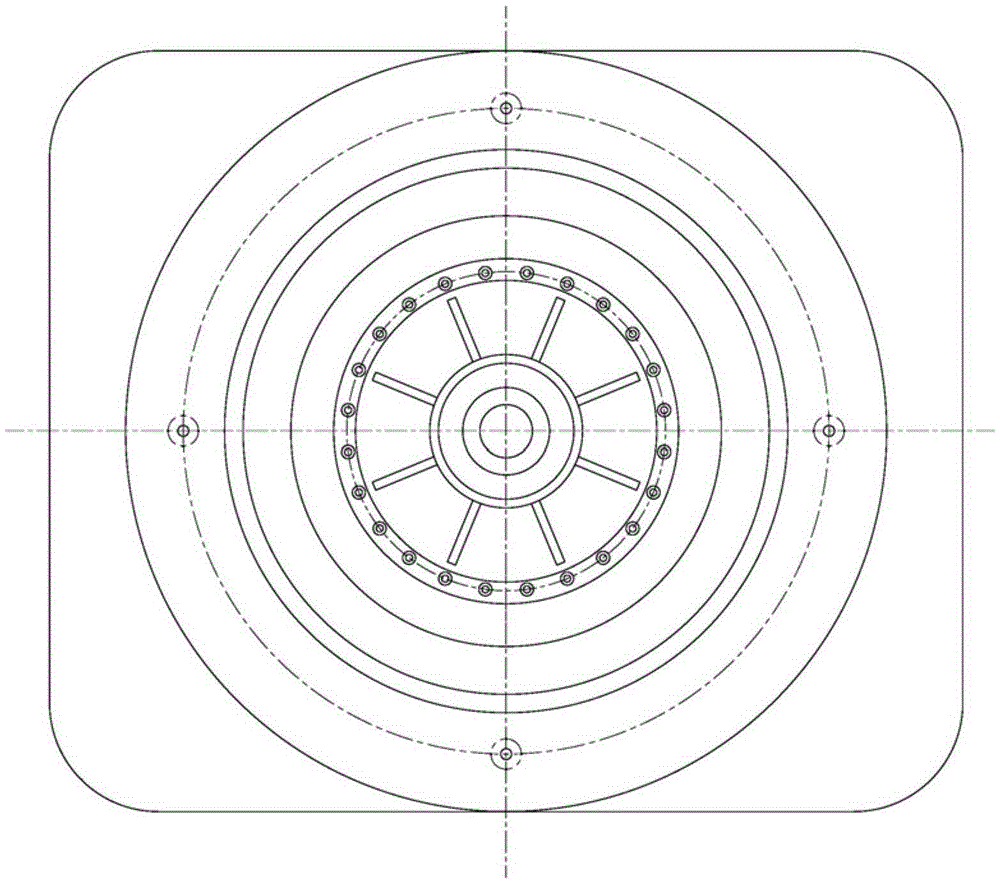

[0013] Such as figure 1 As shown, a bidirectional loading double steering water lubricated thrust bearing test device with pretightening force is composed of the following components, motor 1, coupling 2, bracket 3, loading shaft 4, rolling bearing 5, loading thrust bearing oil groove 6 , Loading piston oil cylinder 7, Loading thrust bearing 8, Loading thrust disc 9, Coupling 10, Tank support 11, Seal 12, Test thrust bearing support system 13, Test thrust bearing pad 14, Thrust disc 15, Flywheel 16, Test shaft 17. Guide tile and seat 18, cover plate 19, test bearing water tank 20. The loading shaft 4 is connected with the motor 1 through the diaphragm coupling 2, the bracket 3 is fixed on the ground, the loading thrust bearing oil tank 6, the water tank bracket 11, and the test bearing water tank 13 are sequentially connected and fixedly installed on the bracket 3, the loading shaft 4, Two sets of loading piston cylinders 7, two sets of loading thrust bearings 8, and loading ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com