Method for detecting diameter-to-thickness ratio of flake alumina particles

A flaky alumina, detection method technology, applied in particle and sedimentation analysis, measuring device, particle size analysis and other directions, can solve the problems of complex operation method, long measurement time, extremely high testing skills, etc., to achieve the mastery of operation method, measurement Stable results and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

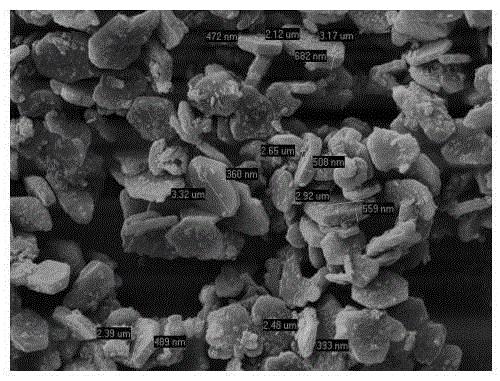

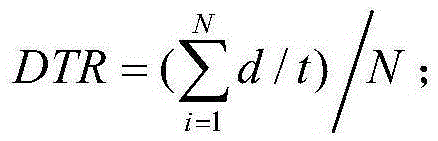

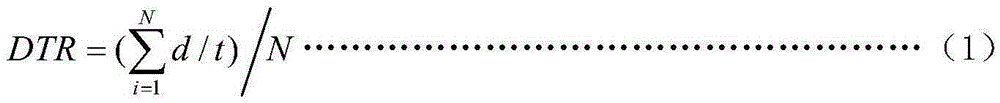

[0022] A method for detecting the diameter-thickness ratio of flaky alumina particles, the specific steps of which are as follows:

[0023] (1) Sample preparation

[0024] 1.1 The sample needs to be dispersed with absolute ethanol, and ultrasonicated on an ultrasonic cell pulverizer for 90 seconds. Use a small dropper to drop a few drops of the sample dilution on the electron microscope sample stage, and dry it for later use.

[0025] 1.2 Place the dried sample stage in the cavity of the ion sputtering instrument to carry out the ion sputtering gold spraying operation. The vacuum degree current is controlled at (0.6-0.8) mA, the sputtering current is controlled at (4-6) mA, Plating time is controlled at (4-6) min.

[0026] (2) Measurement steps

[0027] Place the sprayed sample on the sample holder of the scanning electron microscope, and observe the appearance of the single crystal particles clearly under the appropriate focal length and magnification according to the opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com