Photosensitive drum drive component and selenium drum including same

A photosensitive drum driving and photosensitive drum technology, which is applied in optics, electrical recording process using charge pattern, equipment using electrical recording process with charge pattern, etc. The problem of high rate, to achieve the effect of low failure rate and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

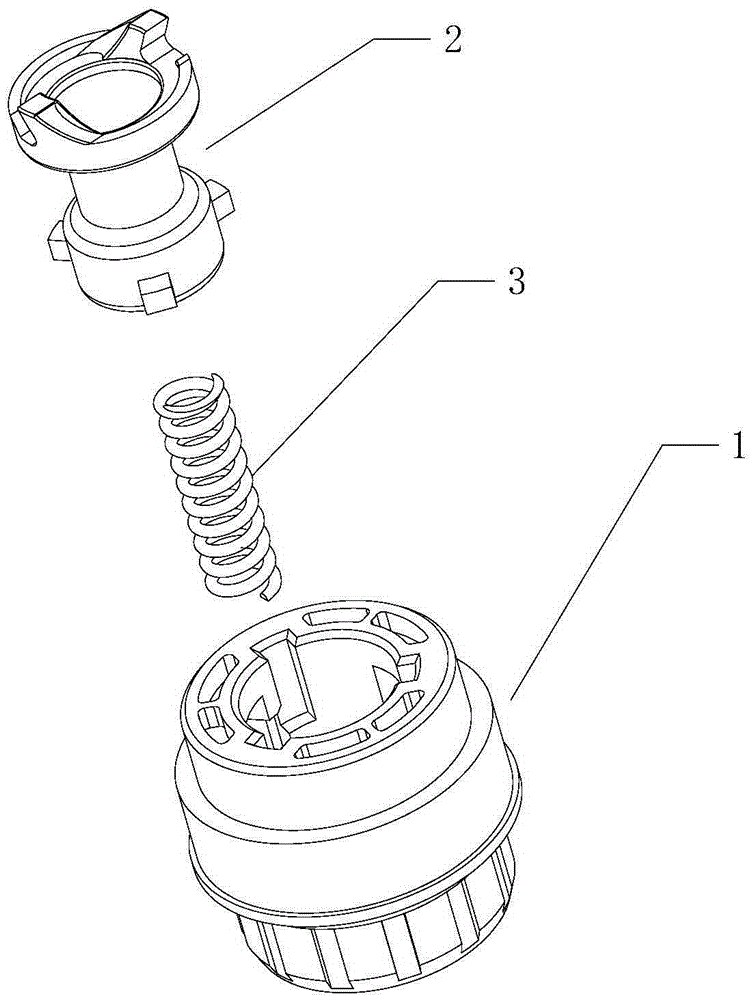

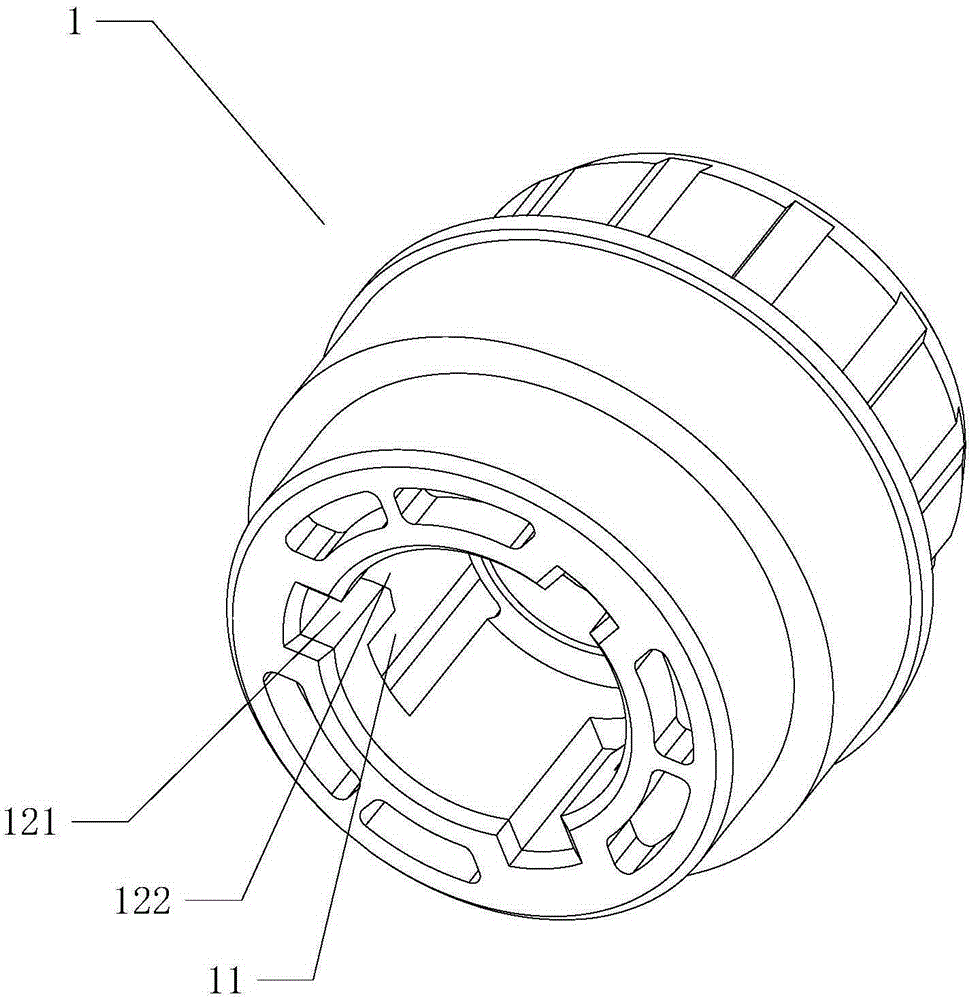

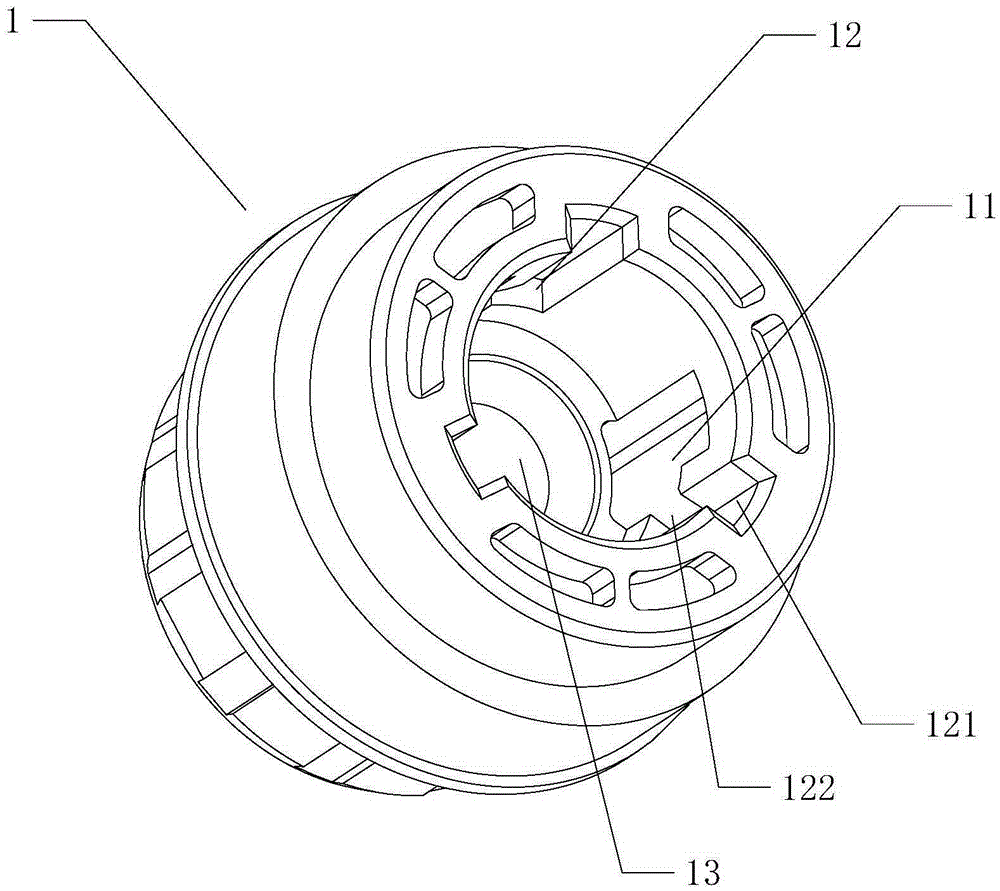

[0061] A photosensitive drum driving assembly, comprising a gear 1 cooperating with the photosensitive drum, a driving force receiving member 2 capable of receiving rotational driving force, a driving force receiving head 21 is arranged on the upper part of the driving force receiving member 2, and a driving force receiving head 21 is arranged on the lower part of the driving force receiving member 2 More than 3 protruding structures 22 protrude from the outer wall of the gear 1. The inner wall of the gear 1 is provided with more than 3 chute 11 along the axial direction of the gear 1. The upper end of the chute 11 is provided with a blocking structure. The side wall of the chute 11 is connected with The guide groove 12, the guide groove 12 communicates with the upper end of the gear 1 and the chute 11, each protruding structure 22 enters the chute 11 from the guide groove 12, and the protruding structures 22 are slidably arranged along the guide groove 12.

[0062] The protrud...

Embodiment 2

[0082] A photosensitive drum driving assembly, comprising a gear 1 cooperating with the photosensitive drum, a driving force receiving member 2 capable of receiving rotational driving force, a driving force receiving head 21 is arranged on the upper part of the driving force receiving member 2, and a driving force receiving head 21 is arranged on the lower part of the driving force receiving member 2 More than 3 protruding structures 22 protrude from the outer wall of the gear 1. The inner wall of the gear 1 is provided with more than 3 chute 11 along the axial direction of the gear 1. The upper end of the chute 11 is provided with a blocking structure. The side wall of the chute 11 is connected with The guide groove 12, the guide groove 12 communicates with the upper end of the gear 1 and the chute 11, each protruding structure 22 enters the chute 11 from the guide groove 12, and the protruding structures 22 are slidably arranged along the guide groove 12.

[0083] The protrud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com