Tab connection method for cylindrical battery cell and pretreatment clamp

A connection method and pretreatment technology, applied to battery pack parts, circuits, electrical components, etc., can solve problems such as position error, easy short circuit on end face, difficult sealing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

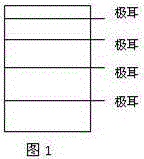

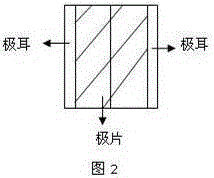

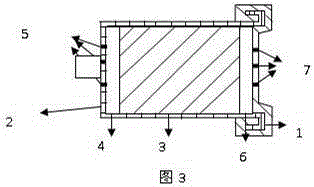

[0025] The coated positive electrode sheet is cut into 120mm wide, the negative electrode sheet is cut into 125mm wide, and 20mm current collectors are reserved at both ends as tabs, and the order of negative electrode, separator, and positive electrode is used for winding. The core is polished into scales on the winding machine, and the pretreatment fixture is used to set the pressing height to 5mm, the necking angle to 5 degrees, the groove width to 4mm, and the groove depth to 3mm. The cell pretreatment fixture is made according to the set parameters such as Figure 7 , Figure 8 shown.

example 2

[0027] The coated positive electrode sheet is cut into 120mm wide, the negative electrode sheet is cut into 125mm wide, and 15mm current collectors are reserved at both ends as tabs, and the order of negative electrode, separator, and positive electrode is used for winding. The core is polished into scales on the winding machine, and the pretreatment fixture is used to set the pressing height to 5mm, the necking angle to 5 degrees, the groove width to 4mm, and the groove depth to 3mm.

example 3

[0029] The coated positive electrode sheet is cut into 120mm wide, the negative electrode sheet is cut into 125mm wide, and 10mm current collectors are reserved at both ends as tabs, and the order of negative electrode, separator, and positive electrode is used for winding. The core is polished into scales on the winding machine, and the pretreatment fixture is used to set the pressing height to 5mm, the necking angle to 5 degrees, the groove width to 4mm, and the groove depth to 3mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com