Rubber coating device for tab

A technology of rubber covering device and tabs, which is applied in the field of tab coating devices, can solve the problems of reducing safety performance, unable to detect and sort the quality of tab coatings, etc., and achieve the effect of enhancing safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

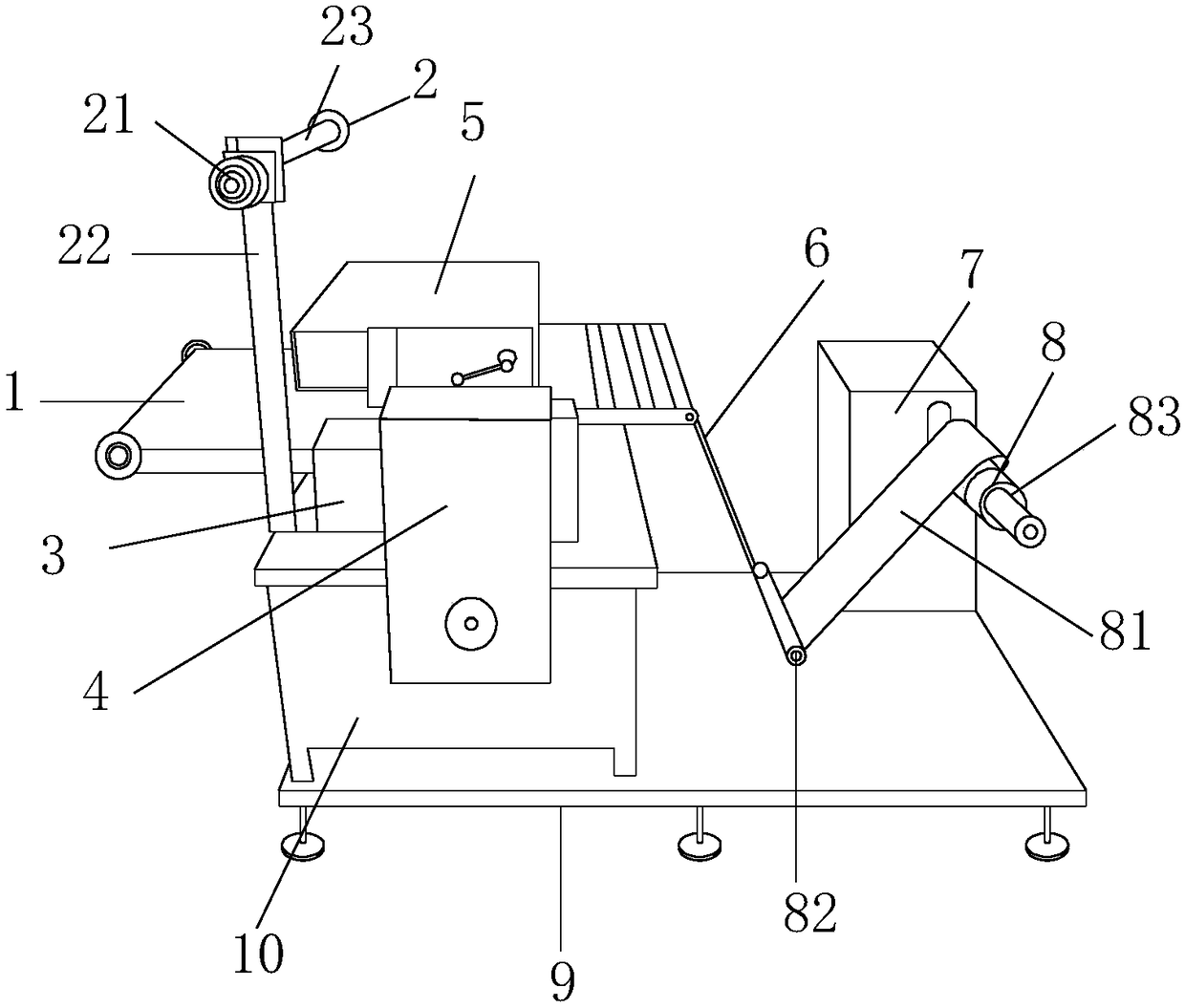

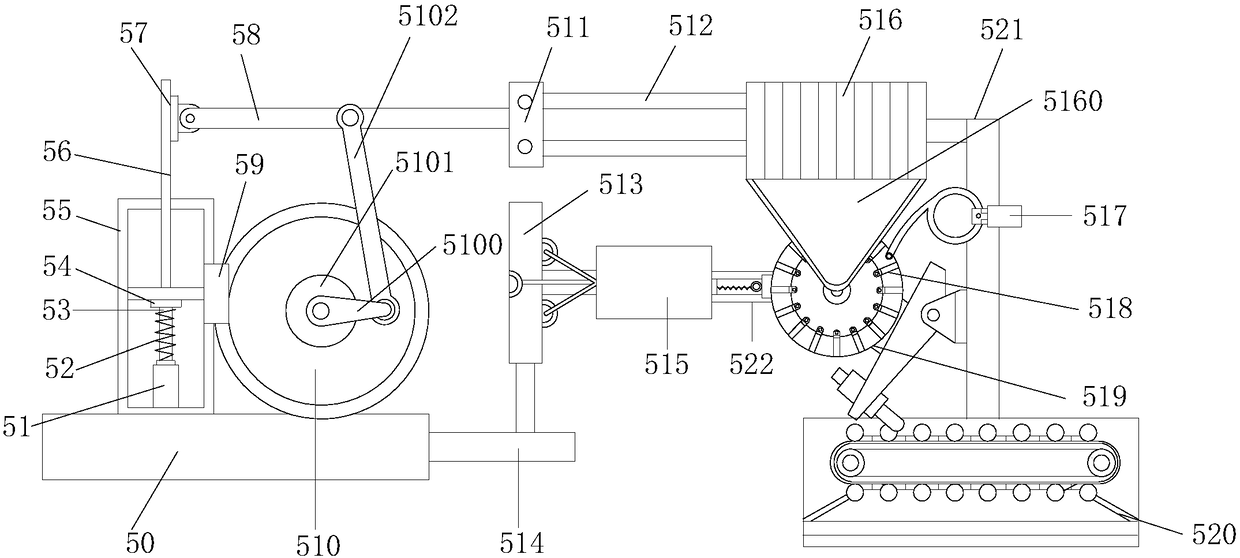

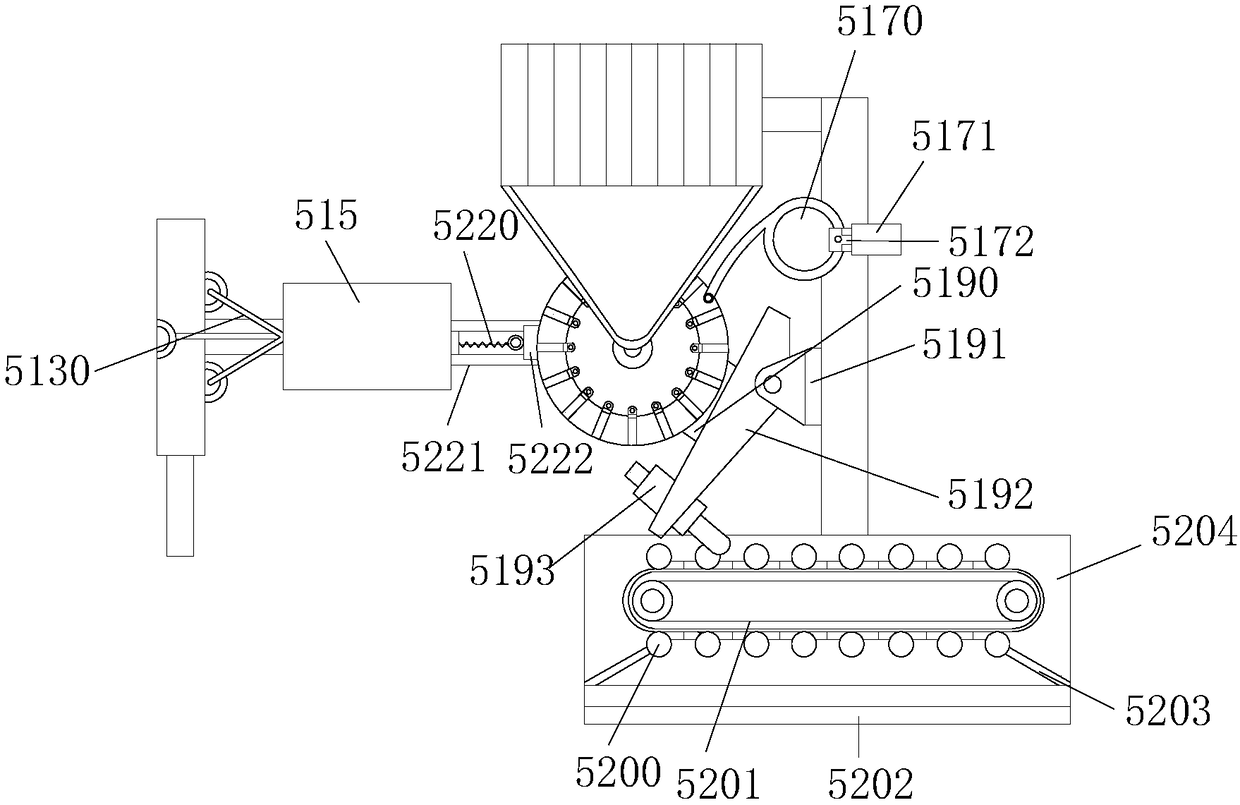

[0025] see Figure 1 to Figure 4, the present invention provides a lug wrapping device, the structure of which includes an object conveyor belt 1, a tab conveying mechanism 2, a tab wrapping former 3, an electric control box 4, a tab wrapping sorting mechanism 5, a conveying traction Belt 6, adhesive tape control seat 7, adhesive tape transmission mechanism 8, machine base 9, workbench 10, said workbench 10 is fixedly installed above the machine base 9 and perpendicular to each other with the machine base 9, said workbench 10 side An electric control box 4 is provided at the end, and the tab overmolding device 3 is set on the top of the workbench 10. The tab translating mechanism 2 is provided on the left side of the tab overmolding device 3, and the tab transmitting mechanism 2 It is composed of a tab shaft 21, a column 22, and a tab conductive roller 23, the tab conductive roller 23 is connected to the tab shaft 21, the tab conductive roller 23 is perpendicular to the column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com