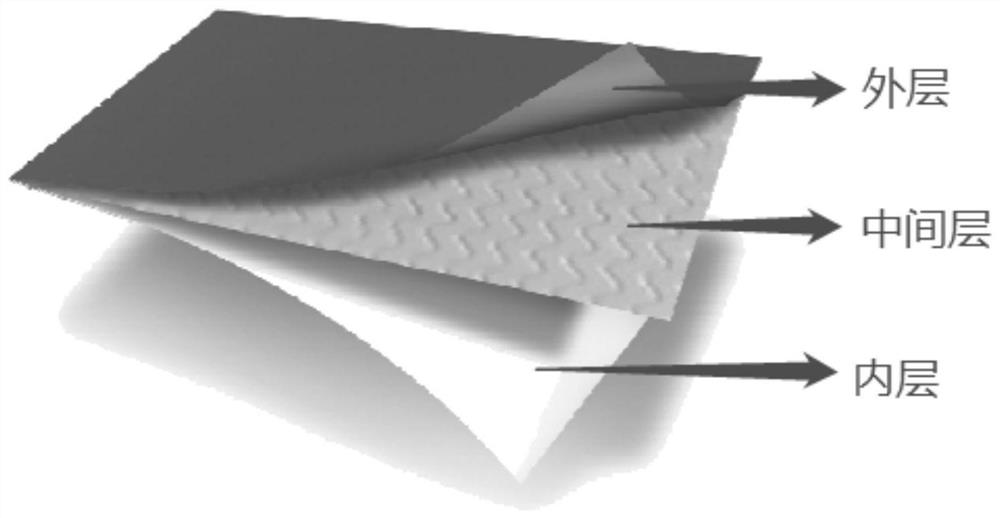

Label film with coating and preparation method thereof

A coating and self-contained technology, which is applied in the directions of labels, chemical instruments and methods, lamination, etc., can solve the problems of simple label film structure, easy printing ink loss, etc., to reduce costs, enhance durable adhesion, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

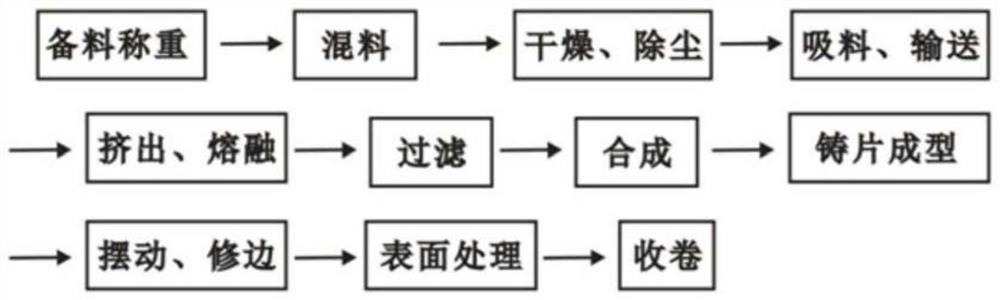

[0052] A kind of preparation method of self-coated label film of the present invention, such as figure 2 shown, including the following steps:

[0053] A. Preparation and weighing: Weigh the outer film raw materials, middle film raw materials, and inner film raw materials, and add them to the corresponding barrels.

[0054] B. Mixing: Stir and mix the raw materials of the outer layer film, the middle layer film and the inner layer film respectively.

[0055] C. Drying and dust removal: After step B is completed, the raw materials of the outer film, the middle film and the inner film are fed into hot air for drying and dust is taken away at the same time.

[0056] D. Suction and transportation: The three raw materials are transported to the hoppers of the three extruders through the vacuum suction device, and the three raw materials enter the feeding section of the extruder by their own weight.

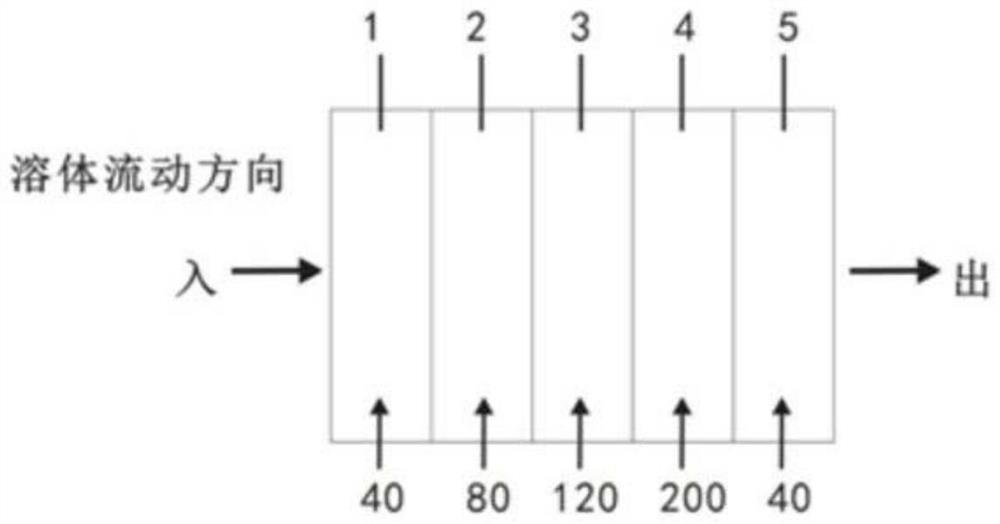

[0057] E. Extrusion and melting: After the three raw materials enter the extrud...

Embodiment 1

[0069] A self-coated label film and a production method thereof, comprising the following steps:

[0070] A. Take by weighing as follows:

[0071] Outer layer film 20kg, wherein the EVA resin of 80% mass parts, the content of VA in the EVA resin is 10%; The EAA resin of 20% mass parts, the content of AA in the EAA resin is 5%;

[0072] Intermediate film 60kg, wherein 58.5% by mass of high-density polyethylene, 19.5% by mass of low-density polyethylene and 22% by mass of white masterbatch;

[0073] Inner film 20kg, wherein 100% by mass of EVA resin, the content of VA in the EVA resin is 18%;

[0074] Add to the corresponding bucket.

[0075] B. Stir and mix the raw materials of the outer layer film, the middle layer film and the inner layer film respectively, and the stirring time is 45 minutes.

[0076] C. After step B is completed, pass the raw materials of the outer layer film, the middle layer film and the inner layer film into hot air for drying respectively. The temper...

Embodiment 2

[0090] A self-coated label film and a production method thereof, comprising the following steps:

[0091] A. Take by weighing as follows:

[0092] Outer layer film 10kg, wherein the EVA resin of 80% mass parts, the content of VA in the EVA resin is 15%; The EAA resin of 20% mass parts, the content of AA in the EAA resin is 10%;

[0093] 80kg of interlayer film, wherein 68.5% by mass of high-density polyethylene, 15.5% by mass of low-density polyethylene and 16% by mass of white masterbatch;

[0094] Inner film 10kg, wherein 100% by mass of EVA resin, the content of VA in the EVA resin is 15%;

[0095] Add to the corresponding bucket.

[0096] B. Stir and mix the raw materials of the outer layer film, the middle layer film and the inner layer film respectively, and the stirring time is 45 minutes.

[0097] C. After step B is completed, pass the raw materials of the outer layer film, the middle layer film and the inner layer film into hot air for drying respectively. The temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Discharge power | aaaaa | aaaaa |

| Discharge power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com