Welding method for tab of soft-package battery cell

A welding method and tab technology, applied in welding equipment, non-electric welding equipment, circuits, etc., can solve problems such as easy breakage, and achieve the effects of avoiding easy breakage, improving safety, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

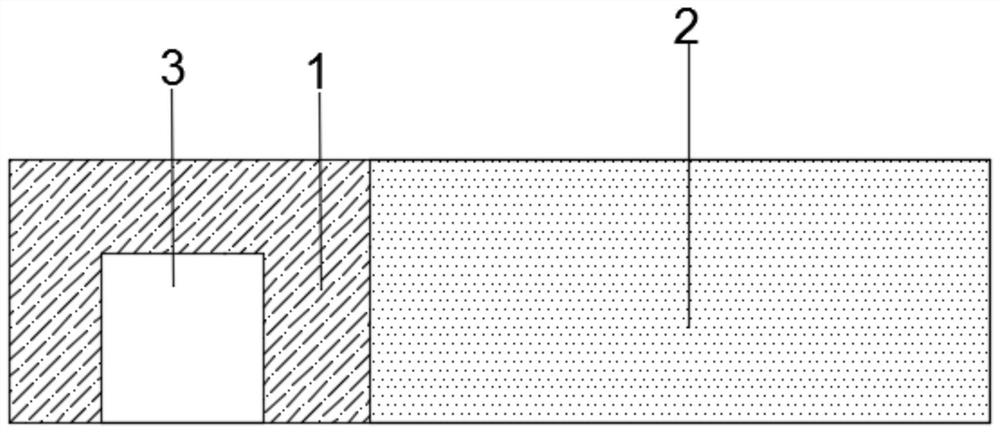

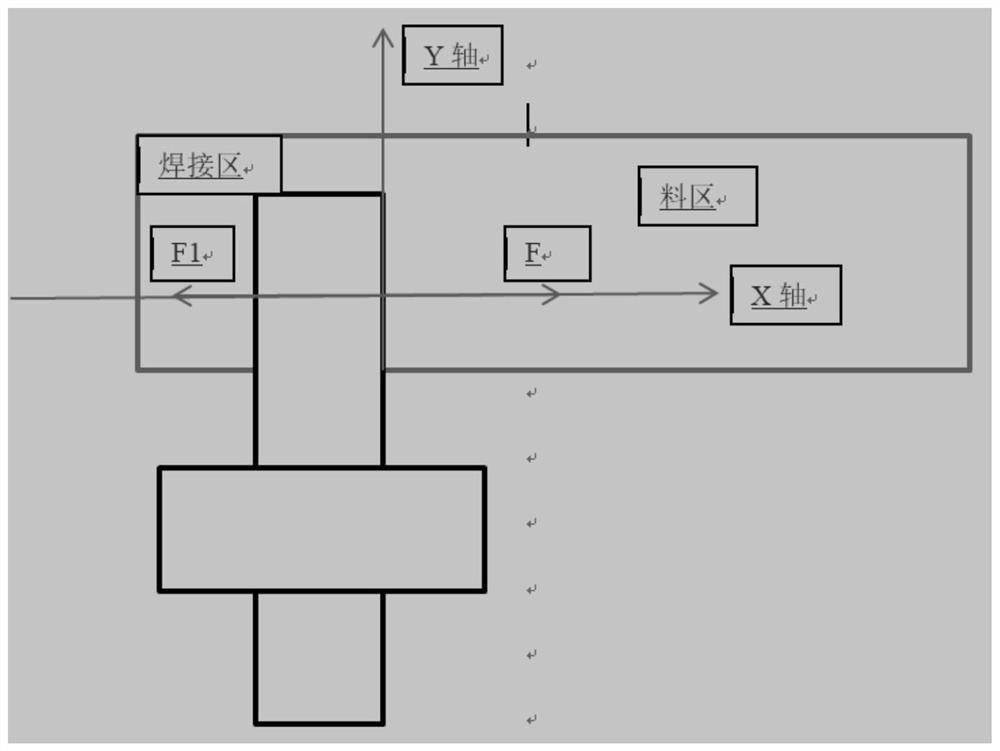

[0031] Such as Figure 1-2 As shown, the present invention provides a method for welding tabs of soft-packed batteries, comprising the following steps:

[0032] (1) Select the positive electrode material or negative electrode material that has been coated, and use it to prepare the positive electrode or negative electrode sheet of the soft-packed battery cell after slitting;

[0033] (2) A welding position 1 is set at one end of the pole piece, and the part connected to the welding position 1 is the paint area 2;

[0034] (3) Select the tab material 3, so that the tab material 3 is coated with the tab glue 4;

[0035] (4) Fix one end of the tab and the welding position 1 together.

[0036] In this embodiment, in step (2), an overlapping area is set in the welding position 1 for fixing with the tab.

[0037] In this embodiment, the specific method of fixing the tab and the welding position 1 in step (4) is as follows: a soldering area 5 is set on the end where the tab and th...

Embodiment 2

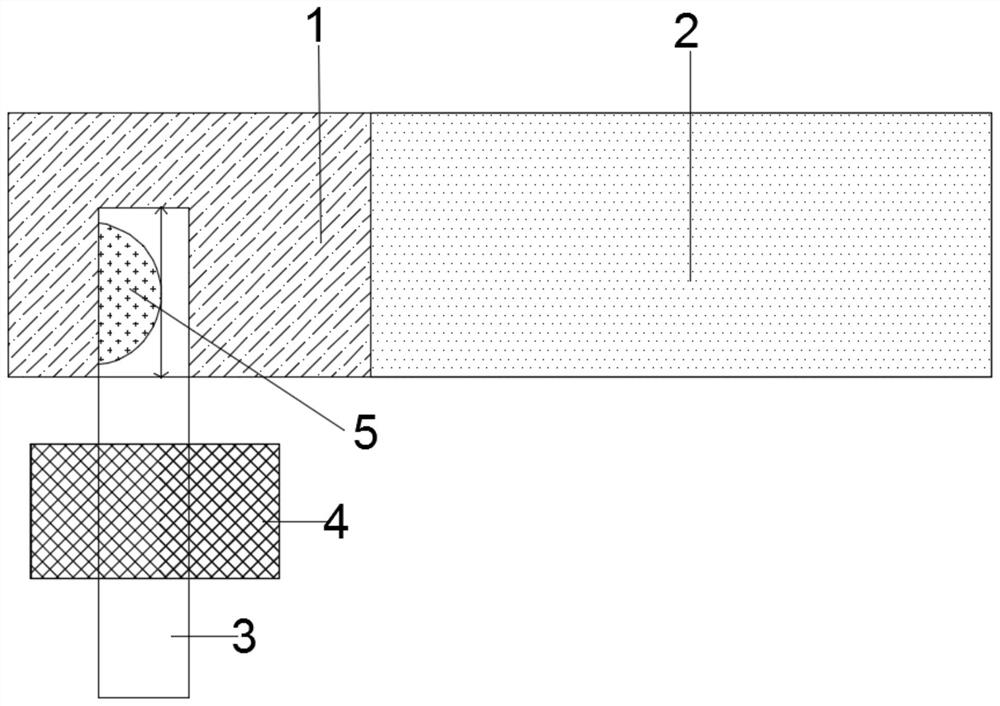

[0045] Such as image 3 As shown, the present invention provides a method for welding tabs of soft-packed batteries, comprising the following steps:

[0046] (1) Select the positive electrode material or negative electrode material that has been coated, and use it to prepare the positive electrode or negative electrode sheet of the soft-packed battery cell after slitting;

[0047] (2) A welding position 1 is set at one end of the pole piece, and the part connected to the welding position 1 is the paint area 2;

[0048] (3) Select the tab material 3, so that the tab material 3 is coated with the tab glue 4;

[0049] (4) Fix one end of the tab and the welding position 1 together.

[0050] In this embodiment, in step (2), an overlapping area is set in the welding position 1 for fixing with the tab.

[0051] In this embodiment, the specific method for fixing the tab and the welding position 1 in step (4) is as follows: a soldering area 5 is provided on the end where the tab and...

Embodiment 3

[0059] Such as Figure 4 As shown, the present invention provides a method for welding tabs of soft-packed batteries, comprising the following steps:

[0060] (1) Select the positive electrode material or negative electrode material that has been coated, and use it to prepare the positive electrode or negative electrode sheet of the soft-packed battery cell after slitting;

[0061] (2) A welding position 1 is set at one end of the pole piece, and the part connected to the welding position 1 is the paint area 2;

[0062] (3) Select the tab material 3, so that the tab material 3 is coated with the tab glue 4;

[0063] (4) Fix one end of the tab and the welding position 1 together.

[0064] In this embodiment, in step (2), an overlapping area is set in the welding position 1 for fixing with the tab.

[0065] In this embodiment, the specific method of fixing the tab and the welding position 1 in step (4) is as follows: a soldering area 5 is set on the end where the tab and the we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com