Lithium battery coating recovery system and slurry separation and recovery device thereof

A technology of separation and recovery and recovery system, which is applied to the device and coating of the surface coating liquid, which can solve the problems of non-recyclable waste materials, and achieve the effect of saving material costs and avoiding mixing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

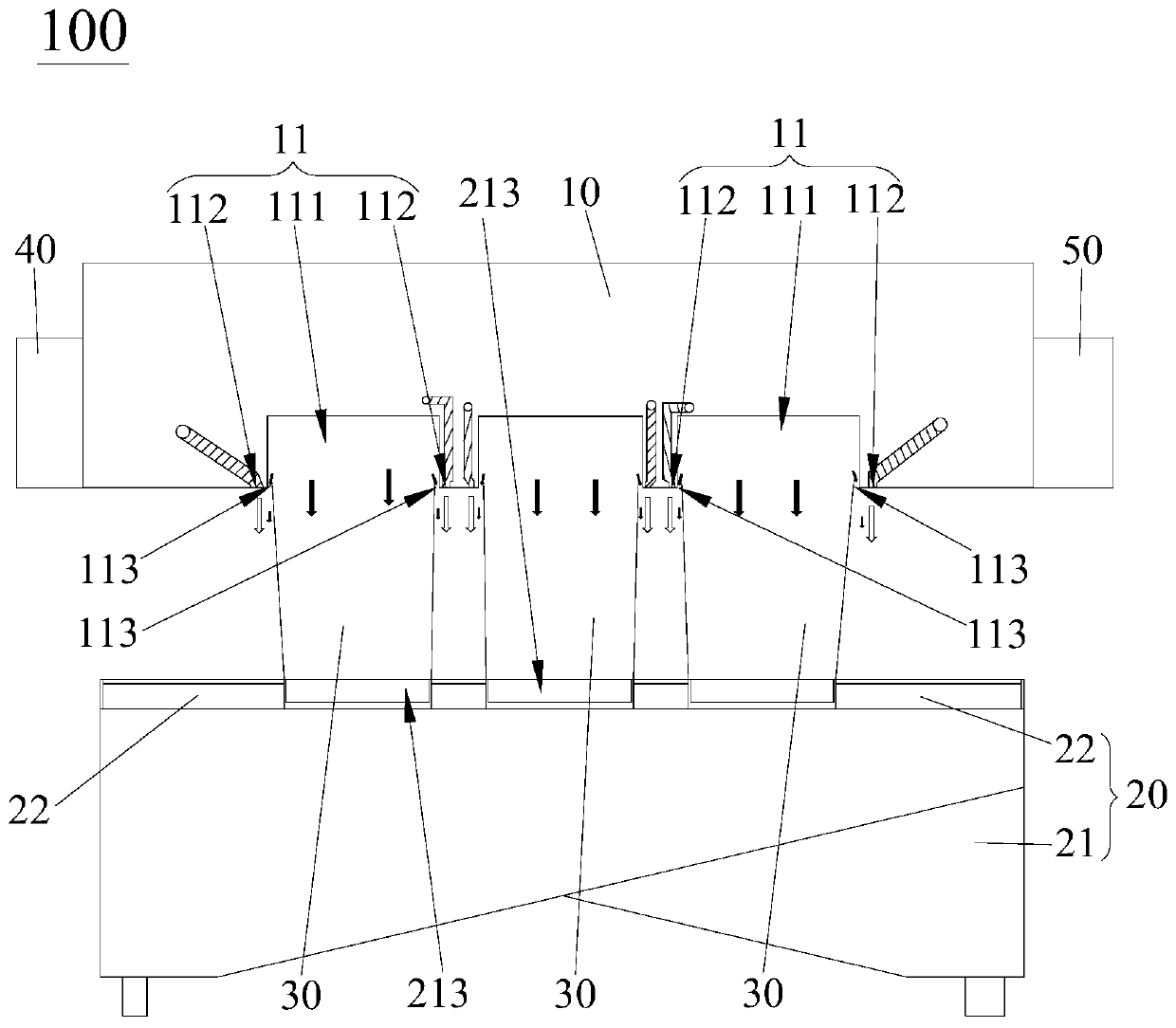

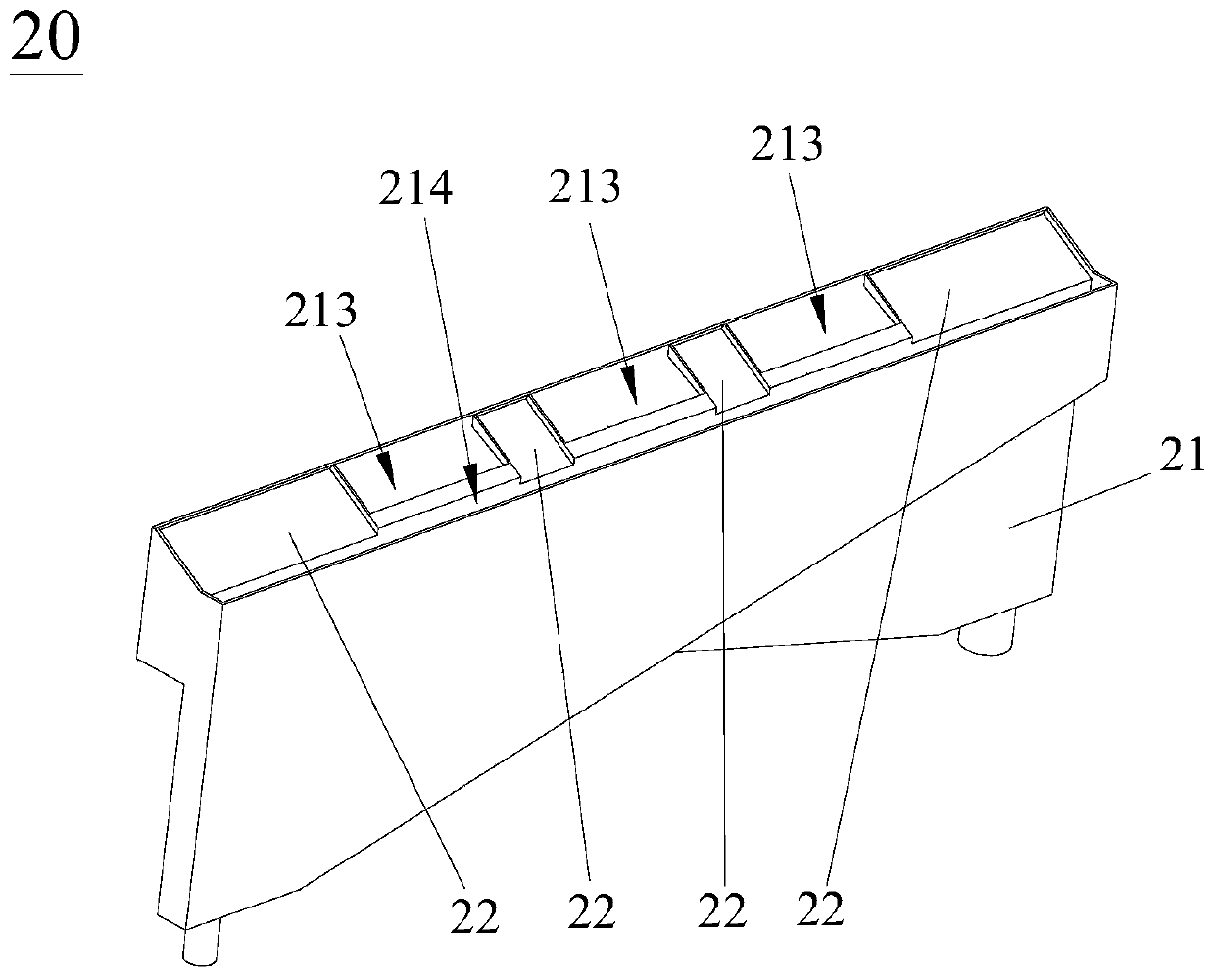

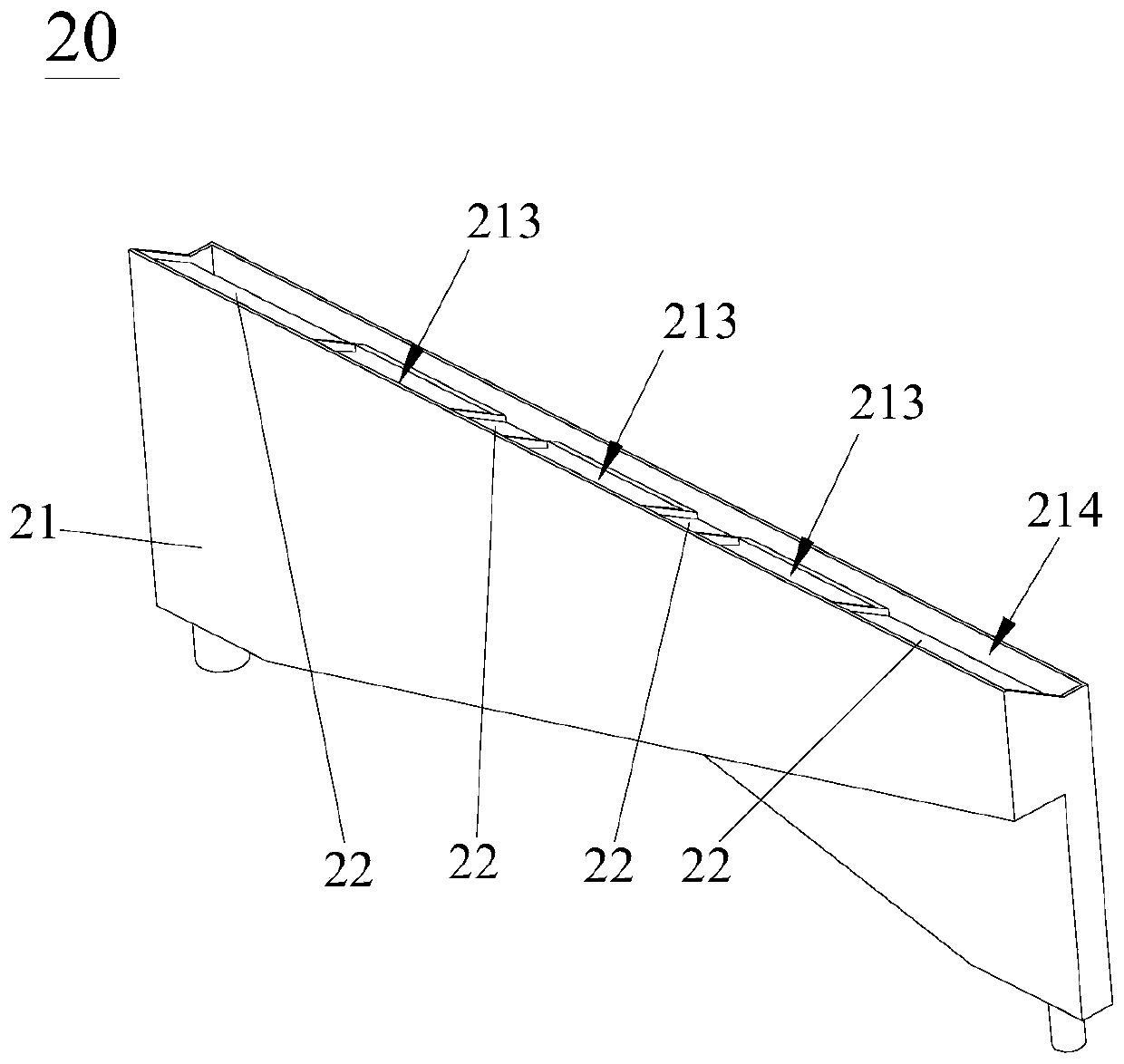

[0026] Such as figure 1 As shown, the lithium battery coating recovery system 100 of the present invention includes a coating die head 10, a slurry separation recovery device 20, a deflector body 30, a slurry supply device 40 and a tab glue supply device 50, and the coating The die head 10 is provided with a coating unit 11, the coating unit 11 includes a slurry outlet 111 and a rubber outlet 112 positioned outside the slurry outlet 111 both sides, the slurry outlet 111 communicates with the slurry feeding device 40, and the rubber The outlet 112 communicates with the lug glue feeding device 50, the deflector body 30 is located directly below the slurry outlet 111, and the upper end of the deflector body 30 extends into the slurry outlet 111, and the deflector bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com