Wind-resistant stabilizing device for radar antenna array

A technology for stabilizing devices and radar antennas, applied in the direction of antenna supports/installation devices, etc., can solve the problems of radar maneuverability, increase the weight of external windproof facilities, increase the difficulty of erection, etc., achieve low cost, simple structure, and easy stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

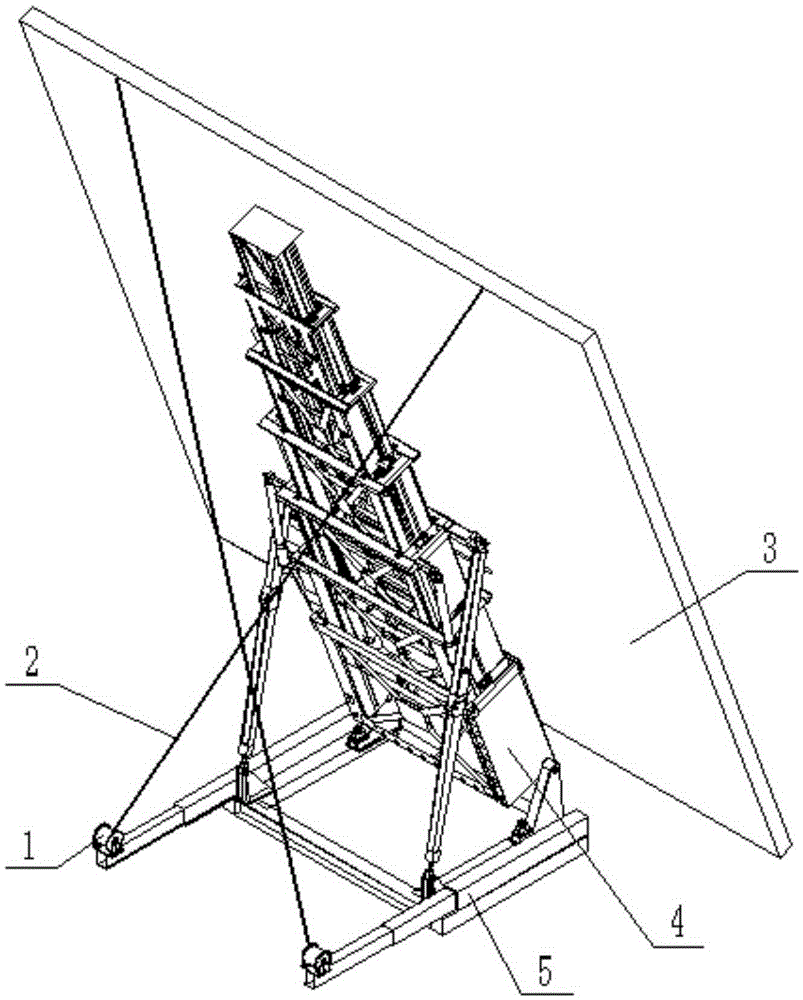

[0022] Combine below figure 1 , 2 This embodiment is described. The present invention relates to the technical field of military radar, more specifically, a radar antenna front wind resistance stabilization device. The radar antenna front wind resistance stabilization device includes a hoist 1, a steel wire rope 2 and an antenna front 3.

[0023] One end of the wire rope 2 is connected to the winch 1 , and the other end of the wire rope 2 is connected to the top of the antenna array 3 . The winch 1 is installed on the supporting platform 5 through bolts, the antenna array 3 is connected with the lifting tower 4, and the lifting tower 4 is installed on the supporting platform 5.

specific Embodiment approach 2

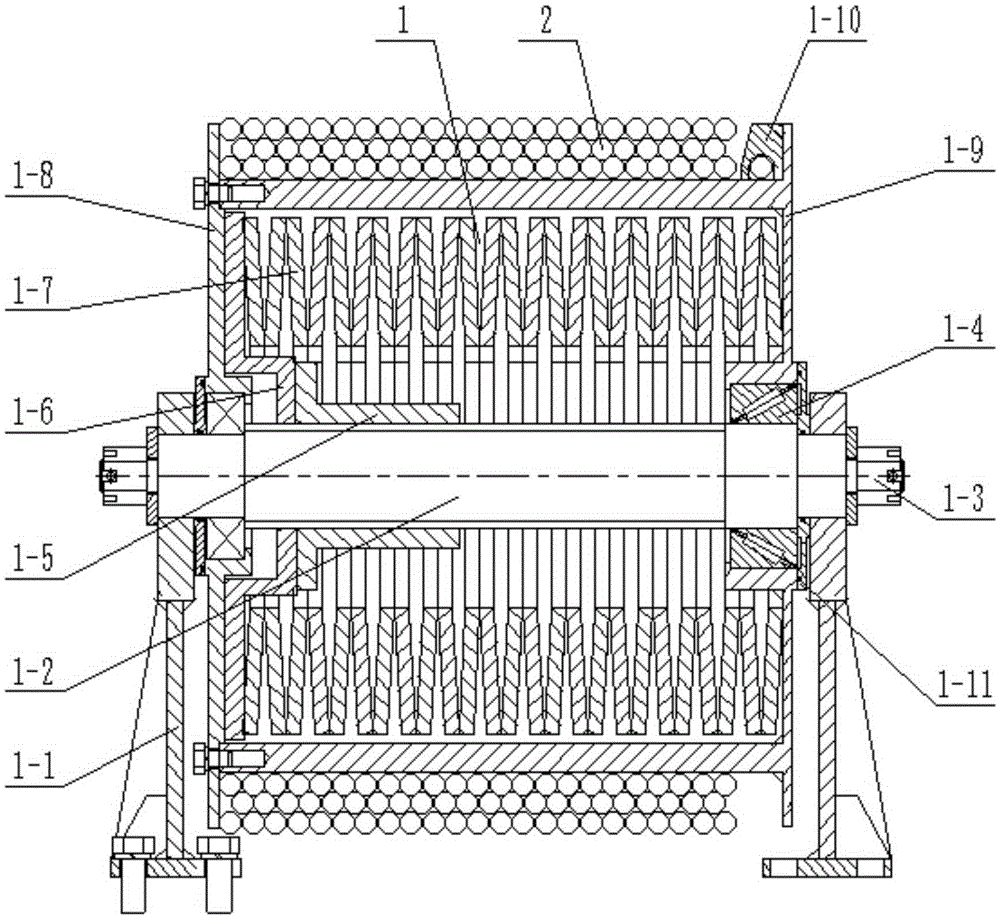

[0024] Combine below figure 1 , 2 To illustrate this embodiment, the winch 1 described in this embodiment includes a bracket 1-1, a ball screw 1-2, a slotted nut 1-3, a bearing 1-4, a ball nut 1-5, a floating plate 1-6, Disc spring 1-7, left reel cover 1-8, right reel cover 1-9, fixed block 1-10 and side sealing plate 1-11, the two ends of described ball screw 1-2 are respectively installed There is a bracket 1-1 and a bearing 1-4, the bracket 1-1 is located on the outside of the bearing 1-4, the bracket 1-1 is flexibly connected with the ball screw 1-2, the inner ring of the bearing 1-4 is connected with the ball screw The bars 1-2 are connected in an interference fit manner. The slotted nut 1-3 is arranged on the ball screw 1-2, and the slotted nut 1-3 is located on the outside of the ball screw 1-2, so as to avoid the gap between the bracket 1-1 and the ball screw 1-2. break away. The ball nut 1-5 and the floating plate 1-6 are all set on the ball screw 1-2, the ball nu...

specific Embodiment approach 3

[0027] Combine below figure 1 , 2 To illustrate this embodiment, the fixed block 1-10 described in this embodiment is provided with a rope threading hole; the steel wire rope 2 passes through the small hole in the fixed block 1-10, which can realize the contact with the radar in the process of ascent and descent. The angle of the antenna front 3 is fixed, so that the direction of the force remains unchanged, which is convenient for maintaining stability and prolonging the service life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com