Connection fitting for converter station valve hall

A technology for connecting fittings and converter stations, which is applied to the installation of output power conversion devices, electrical components, and busbars, and can solve problems such as temperature rise of flexible wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

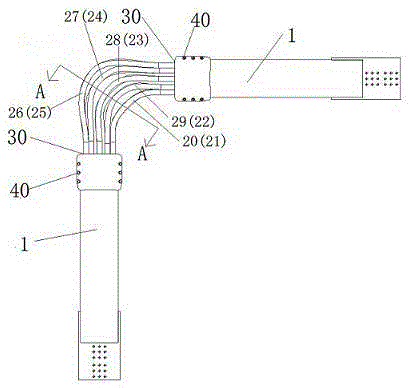

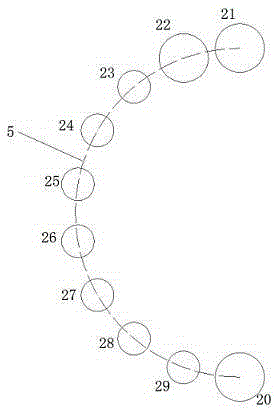

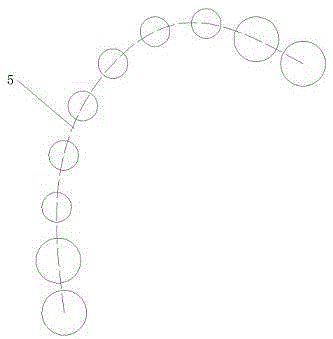

[0019] Examples of connecting fittings for the valve hall of the converter station in the present invention figure 1 and figure 2 As shown: the connecting hardware for the valve hall of the converter station includes two pipe busbars 1 arranged perpendicular to each other, that is, the angle between the length extension directions of the two pipe busbars 1 is 90 degrees. There are 10 bent flexible wires connected between the two pipe busbars 1, and the center line of each flexible wire on the section perpendicular to the extension direction of each flexible wire at the bend of the flexible wires is a curve 5, which is distributed on two sides of the curve 5. The flexible conductor at the end is called the end flexible conductor, and the flexible conductor distributed between the end flexible conductors is called the middle flexible conductor, and the diameter of the end flexible conductor is larger than that of the middle flexible conductor. The ten flexible wires are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com