Ceramic crucible for galvanizing furnace and production method thereof

A technology for ceramic crucibles and furnaces, which is applied in the field of ceramic crucibles for galvanizing furnaces and its production. It can solve the problems of furnace gas air pollution, affecting the quality of galvanizing, and short service life, so as to achieve uniform force on the crucible and improve heat resistance. Vibration and performance, the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A ceramic crucible for a galvanizing furnace. The material of the crucible is composed of 252kg of silicon carbide sand, 48kg of metal silicon powder, 3kg of clay, 10kg of micropowder binder, 1kg of rare metal yttrium, and 17.2kg of glue.

[0023] The manufacture method of ceramic crucible for described galvanizing furnace, its steps are as follows:

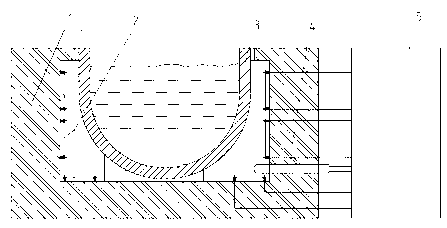

[0024] (1) Mold production: Design and manufacture crucible molds for machine press molding according to the silicon carbide special ceramic crucible 3. Sufficient draft angle and rounded corners should be left in the mold design to make demoulding smooth and improve the yield;

[0025] (2) Mixing: Mix 252kg of silicon carbide sand, 48kg of metal silicon powder, 3kg of clay, 10kg of micropowder binder, 1kg of rare metal yttrium, and 17.2kg of glue with a planetary mixer for 30 minutes;

[0026] (3) Molding: After assembling the manufactured mold, weigh the mixed material according to the calculated weight, add it into the ...

Embodiment 2

[0031] A ceramic crucible for a galvanizing furnace. The material of the crucible consists of 248.4kg silicon carbide sand, 39.744kg metal silicon powder, 2.3kg clay, 9.9kg micropowder binder, 0.9kg rare metal yttrium, and 16.6kg glue.

[0032] The manufacture method of ceramic crucible for described galvanizing furnace, its steps are as follows:

[0033] (1) Mold production: Design and manufacture crucible molds for machine press molding according to the silicon carbide special ceramic crucible 3. Sufficient draft angle and rounded corners should be left in the mold design to make demoulding smooth and improve the yield;

[0034] (2) Mixing: Mix 248.4kg of silicon carbide sand, 39.744kg of metal silicon powder, 2.3kg of clay, 9.9kg of micropowder binder, 0.9kg of rare metal yttrium, and 16.6kg of glue with a planetary mixer, and the mixing time is 30 minute;

[0035] (3) Molding: After assembling the manufactured mold, weigh the mixed material according to the calculated wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com