Etching method of thick copper circuit board

A circuit board and etching technology, which is applied to the etching field of thick copper circuit boards, can solve the problems that affect the productivity and output of the etching production line, affect the quality and production efficiency of other boards, and cannot be completely eliminated, so as to improve the etching efficiency and reduce the cost. , the effect of reducing the line width difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

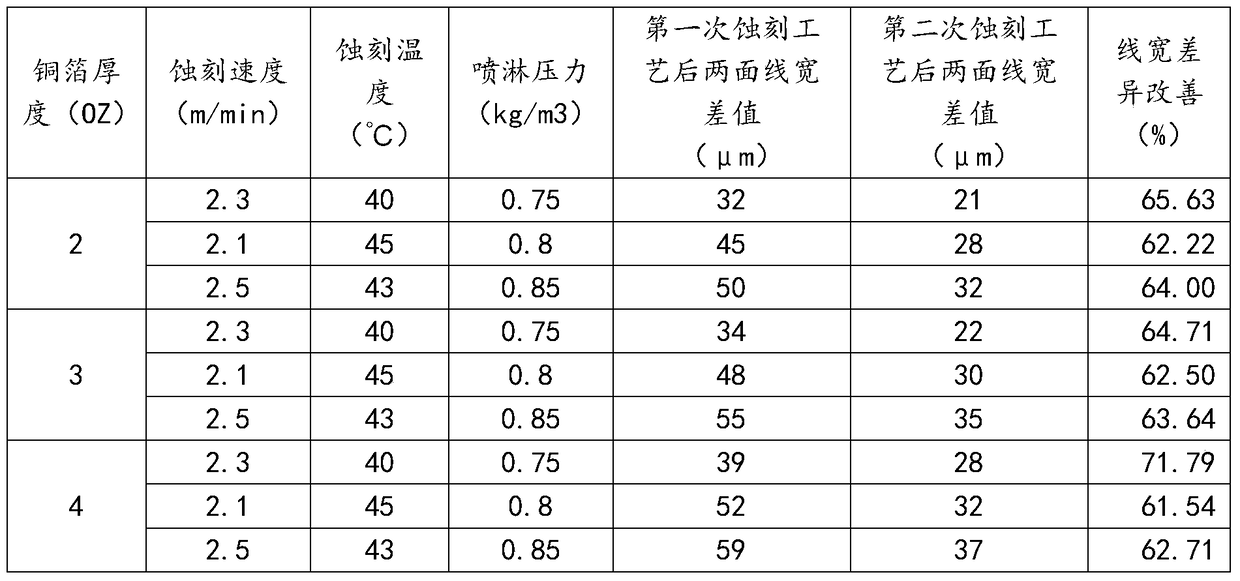

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

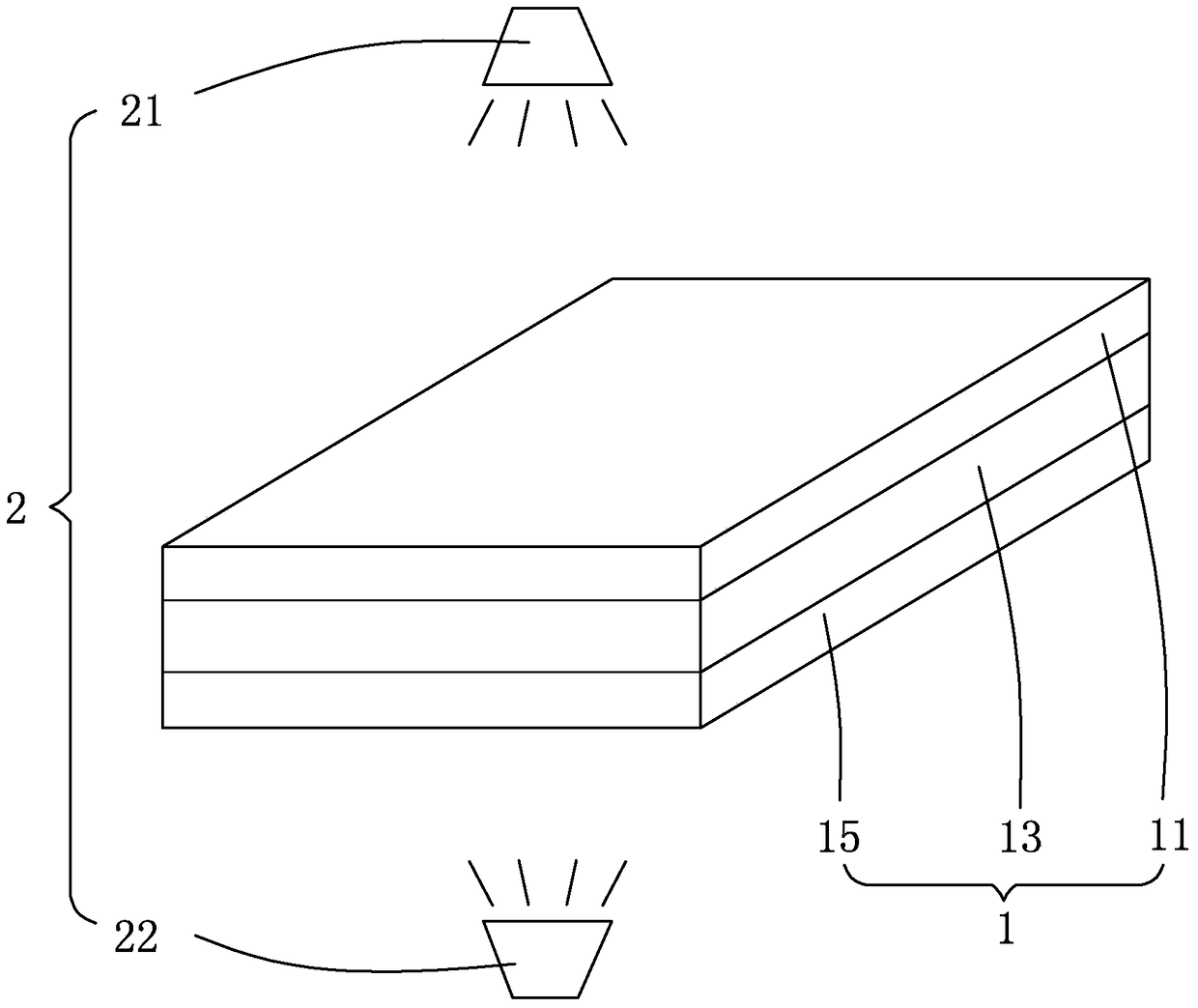

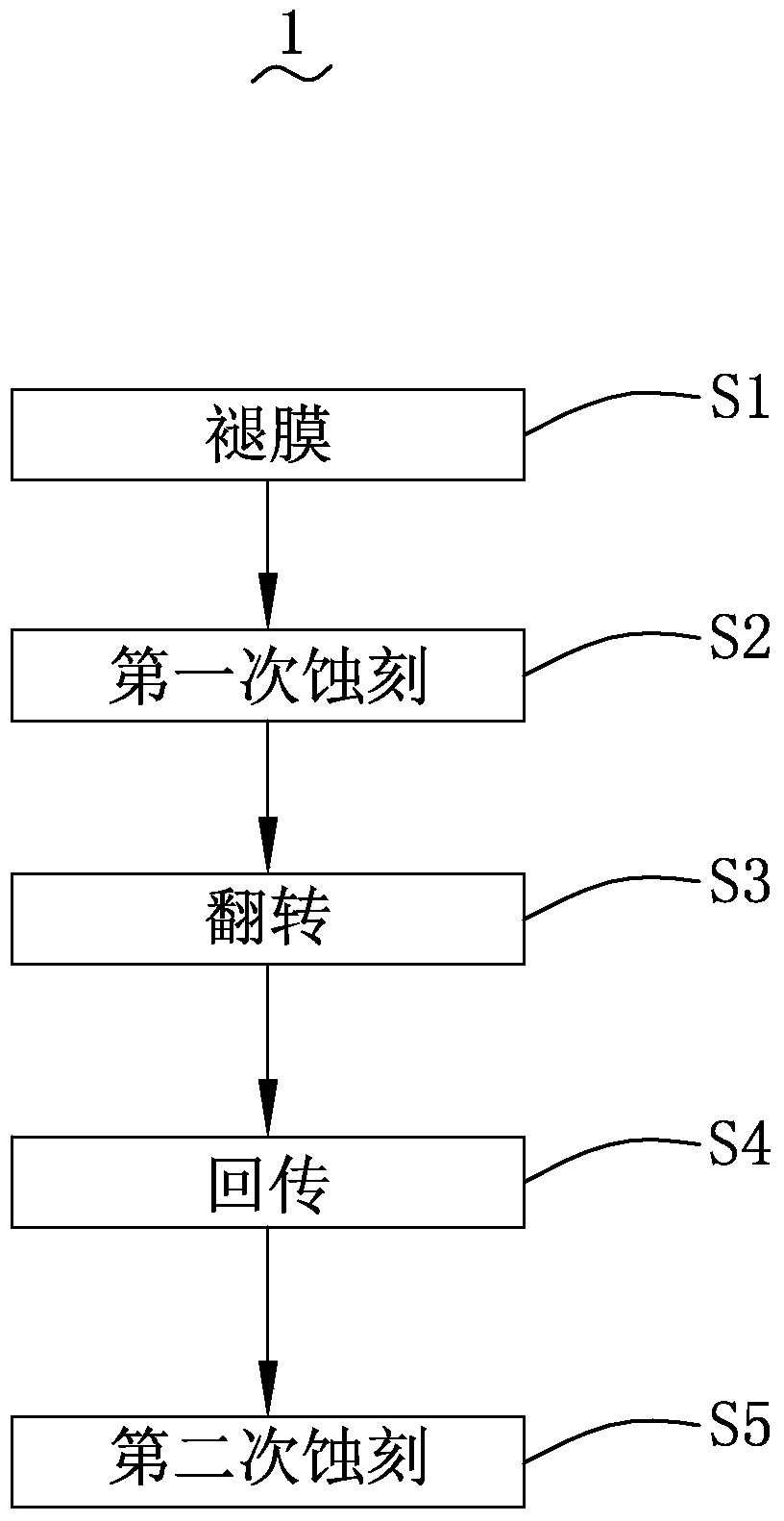

[0030] see figure 1 , is a schematic diagram of etching a thick copper circuit board in the method for etching a thick copper circuit board of the present invention. The thick copper circuit board 1 includes a top copper layer 11 , a substrate 13 and a bottom copper layer 15 . The top copper layer 11 and the bottom copper layer 15 are respectively disposed on two sides of the substrate 13 .

[0031] The top copper layer 11 and the bottom copper layer 15 are thick copper foil, and the thickness of the thick copper foil is above 2OZ.

[0032] The etching production line for the etching process includes a film stripping station, an etching station, a tin stripping station, a turning device (not shown) and a return device (not shown). The thick copper circuit board 1 is transported horizontally along the etching production line, and passes through the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com