Chain-tooth type film residue recycling machine

A recycling machine and residual film technology, applied in the direction of collectors, agricultural machinery and implements, applications, etc., can solve the problems of poor operation reliability, low recovery rate of broken small residual film and residual film in the plough layer, etc., and achieve recycling operations. Stable, simple structure and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

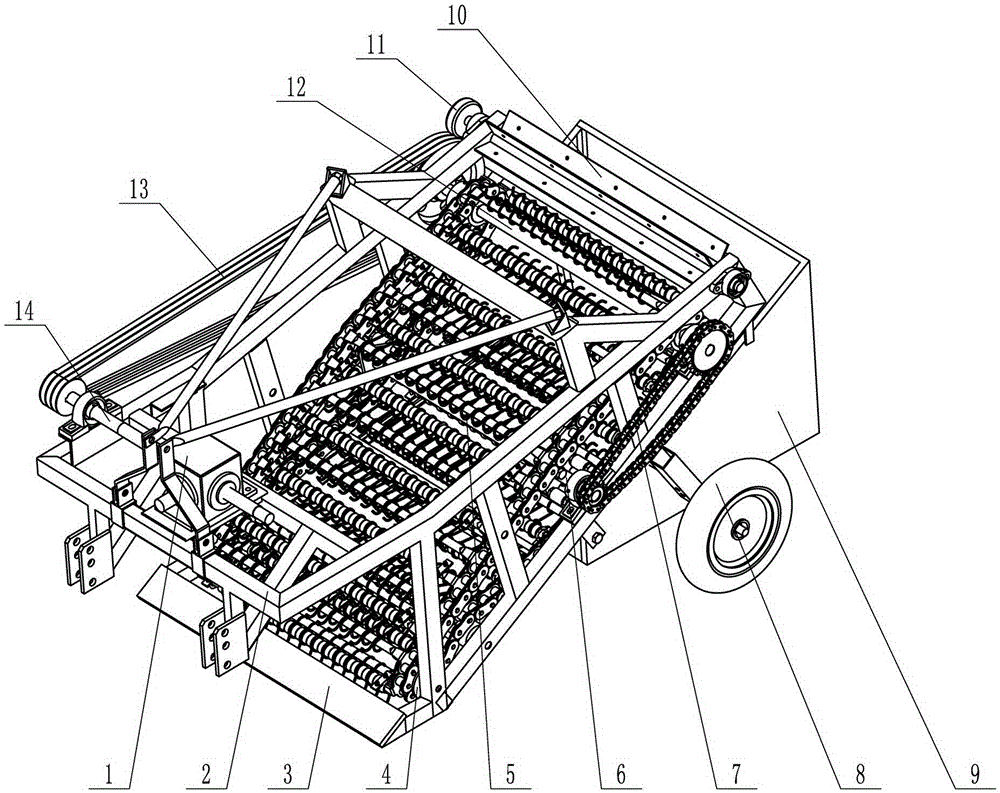

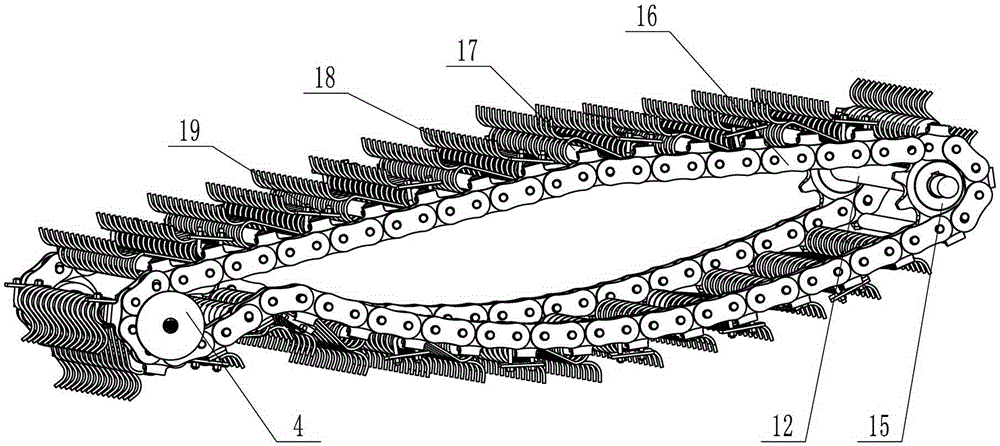

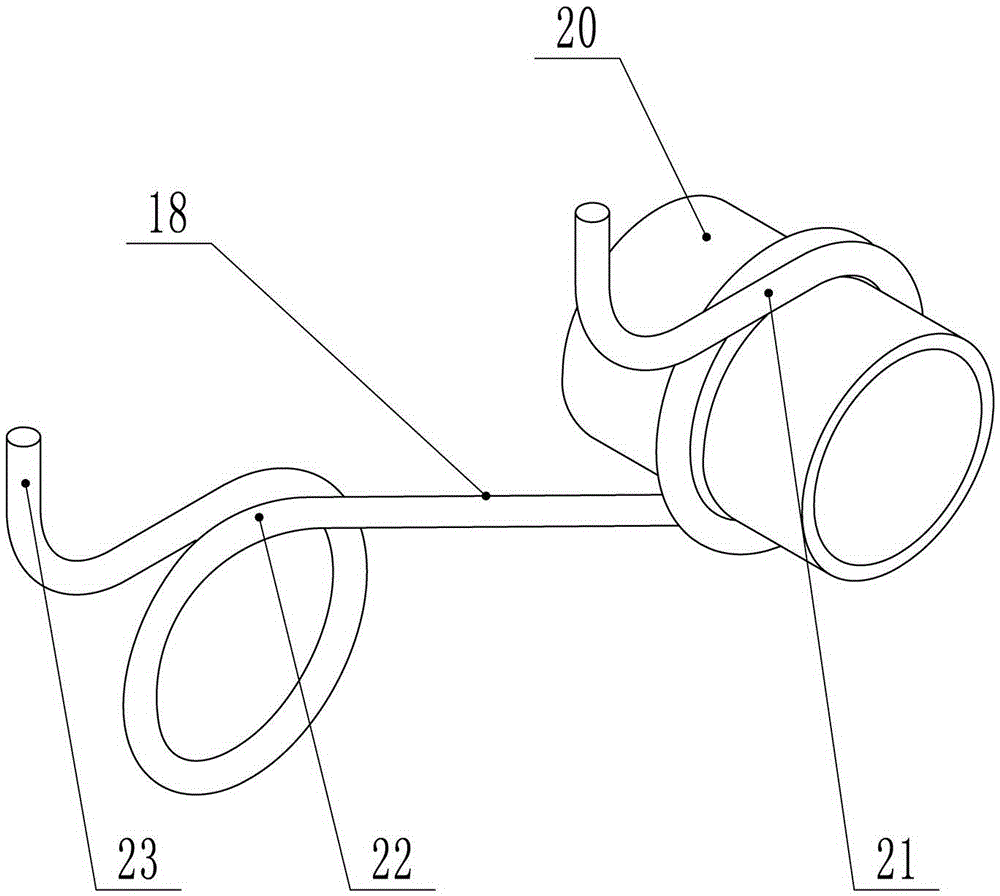

[0010] A sprocket type residual film recovery machine, such as figure 1 , figure 2 Shown, comprise the frame 2 that transmission case 1 and road wheel 8 are housed, the rear portion of frame 2 above road wheel 8 is respectively provided with residual film box 9, driven shaft 12 and unloading film roller 10 from bottom to top, On the central axis of the unloading film roller 10, four scrapers are evenly spaced along its axial direction to scrape the residual film into the residual film box 9.

[0011] The front end of the frame 2 below the gearbox 1 is provided with a soil lifting shovel 3 and an idler roller 4 sequentially from front to back, and the power output shaft 14 of the gearbox transmits the rotation of the driven shaft 12 through the belt 13, and the end of the driven shaft 12 The belt pulley provided is in contact with the friction wheel 11 provided at the end of the film unloading roller 10; the film unloading roller 10 is driven to rotate by the friction wheel 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com