An auger type pig manure automatic cleaning equipment

An automatic cleaning and auger technology, applied in animal houses, applications, animal husbandry, etc., can solve the problems of low efficiency, increased labor costs, waste of labor, etc., to save labor, improve construction efficiency, and save cleaning costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

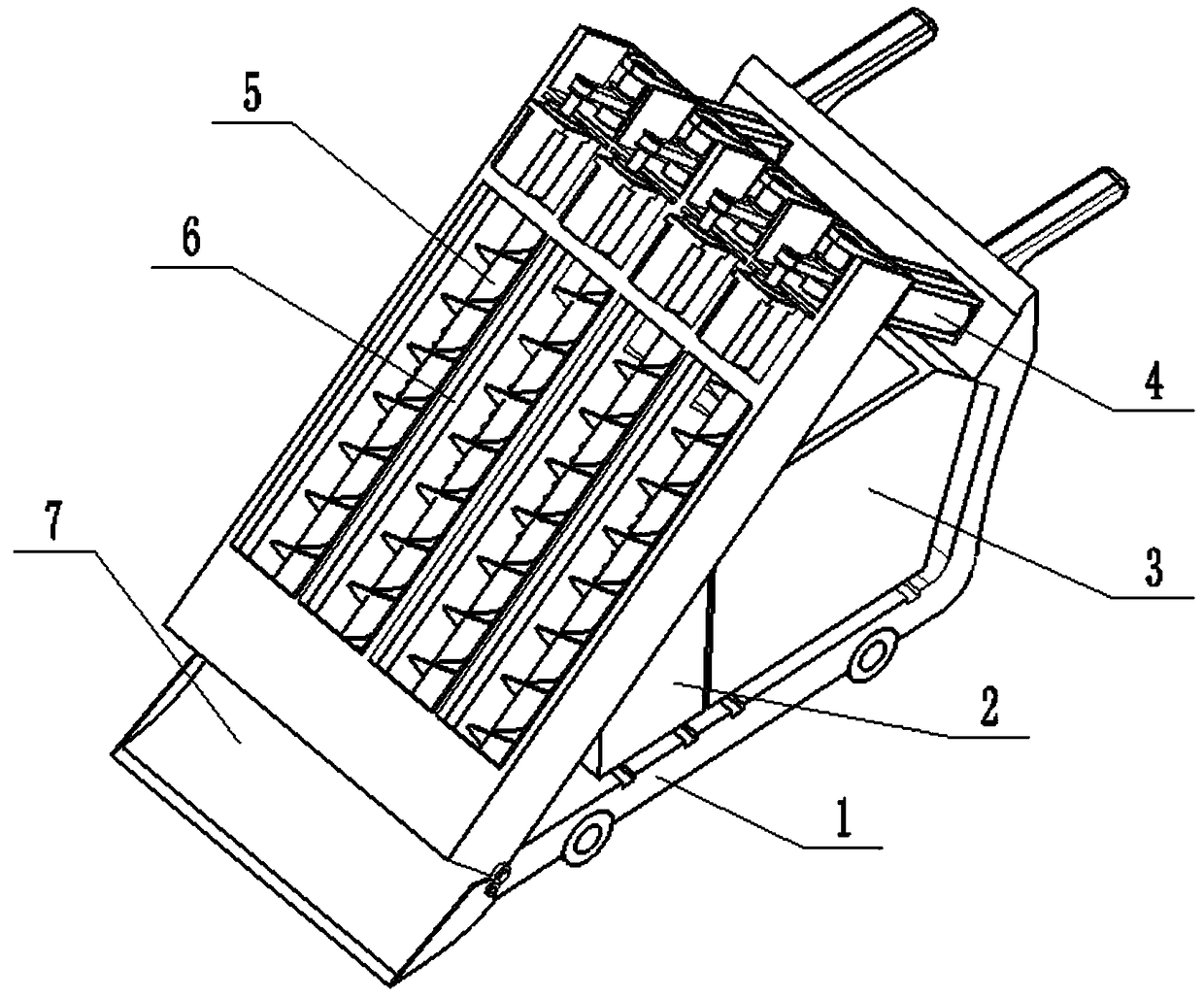

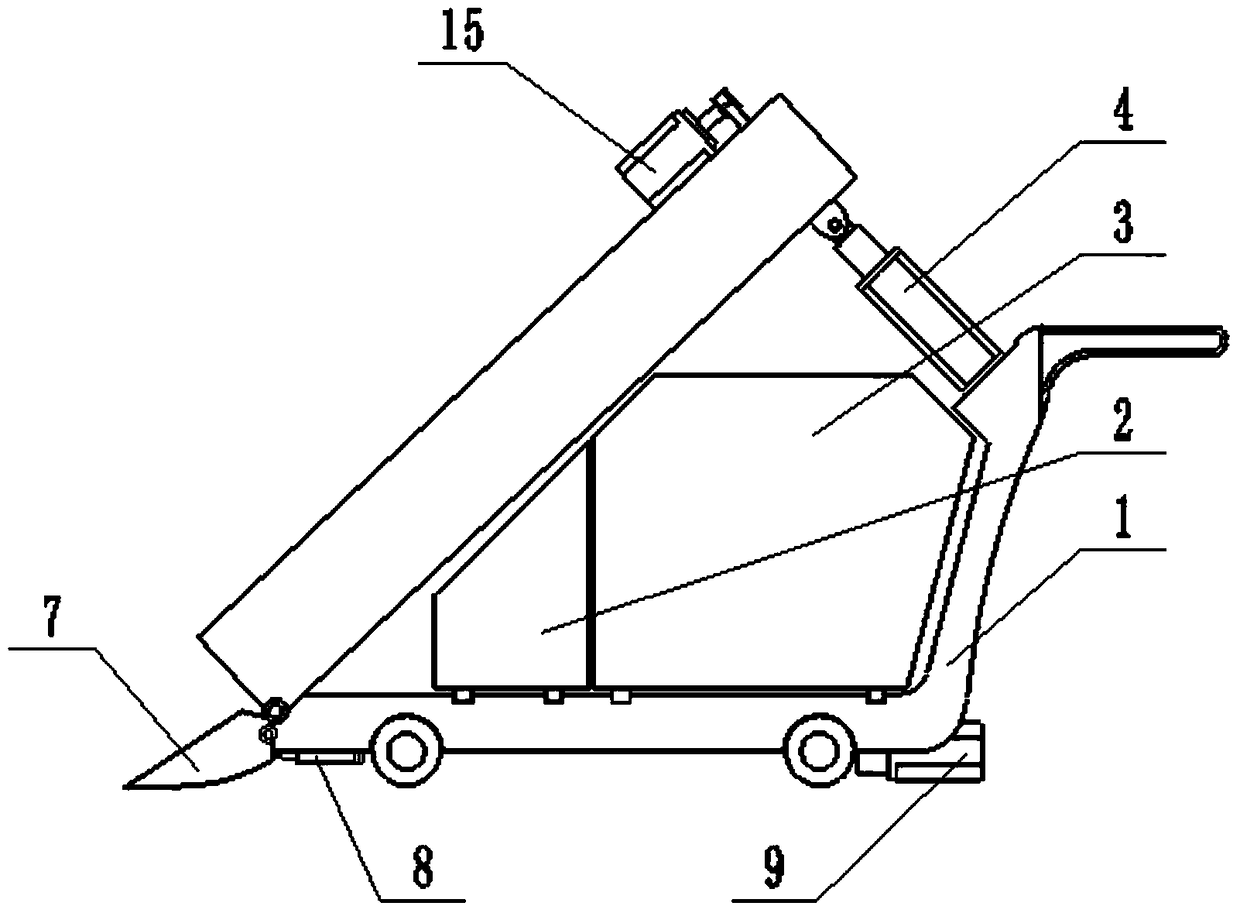

[0012] An auger-type pig manure automatic cleaning equipment, which is composed of a vehicle-mounted device 1, a manure water tank 2, a dry manure tank 3, a hydraulic telescopic cylinder 4, an auger device 5, a transmission device 6 and a manure scraper 7, and is characterized in that: The vehicle-mounted device 1 is equipped with a manure water tank 2, a dry manure tank 3, and a hydraulic telescopic cylinder 4. The vehicle-mounted device 5 is connected to the transmission device 1 through the hydraulic telescopic cylinder 4. The manure scraper 7 is installed on the front of the vehicle-mounted device 1, and the transmission device 6 is tilted. It is installed on the top of the vehicle-mounted device 1 at a certain angle, and the auger device 5 is installed inside the transmission device 6 .

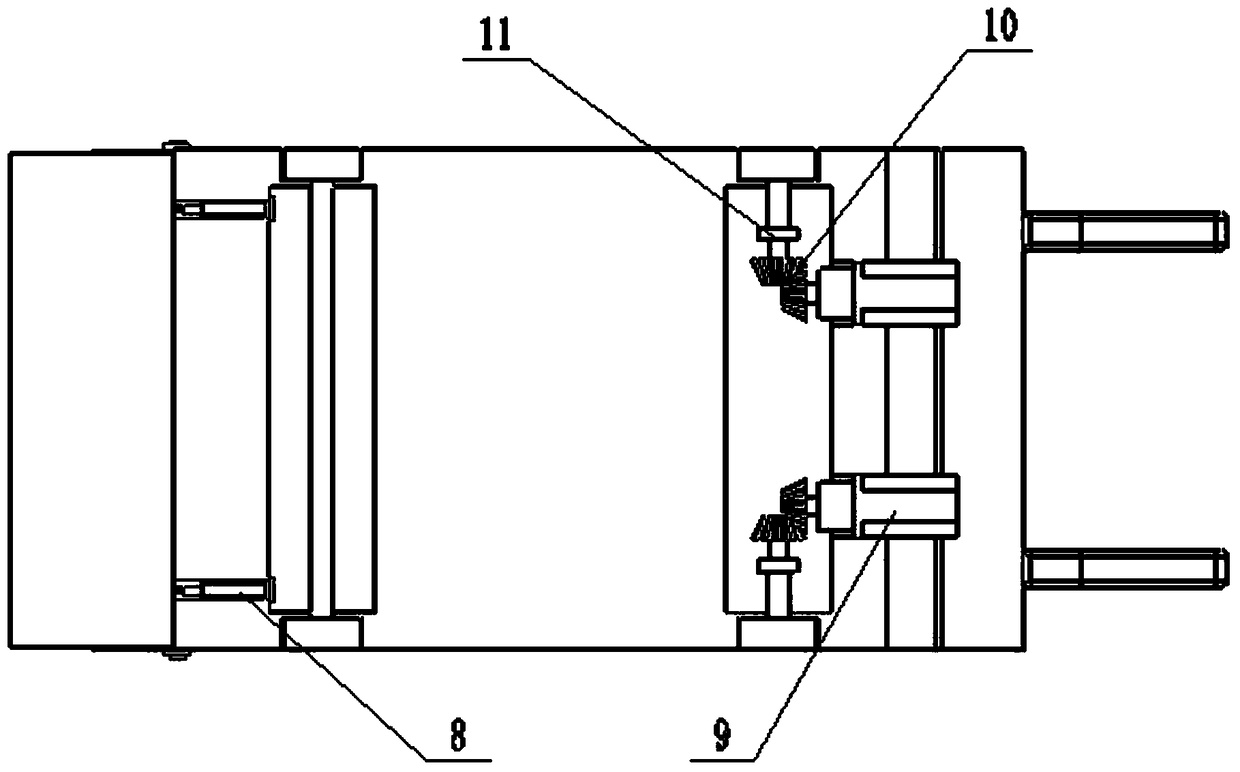

[0013] The vehicle-mounted device 1 is composed of a cylinder 8, a differential drive motor 9, a bevel gear set 10, a supporting and stable bearing 11, a groove 12 and a rail 13; , the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com