A shoe front lining/back cover processing machine and its processing technology

A front lining and back cover technology, which is applied in shoemaking machinery, shoe uppers, footwear, etc., can solve problems that affect the appearance of shoes, stitching quality and stitching efficiency, affect the processing quality of front lining/back cover, and affect production efficiency, etc. , to achieve the effects of excellent product identity, good cooling effect, improved production quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

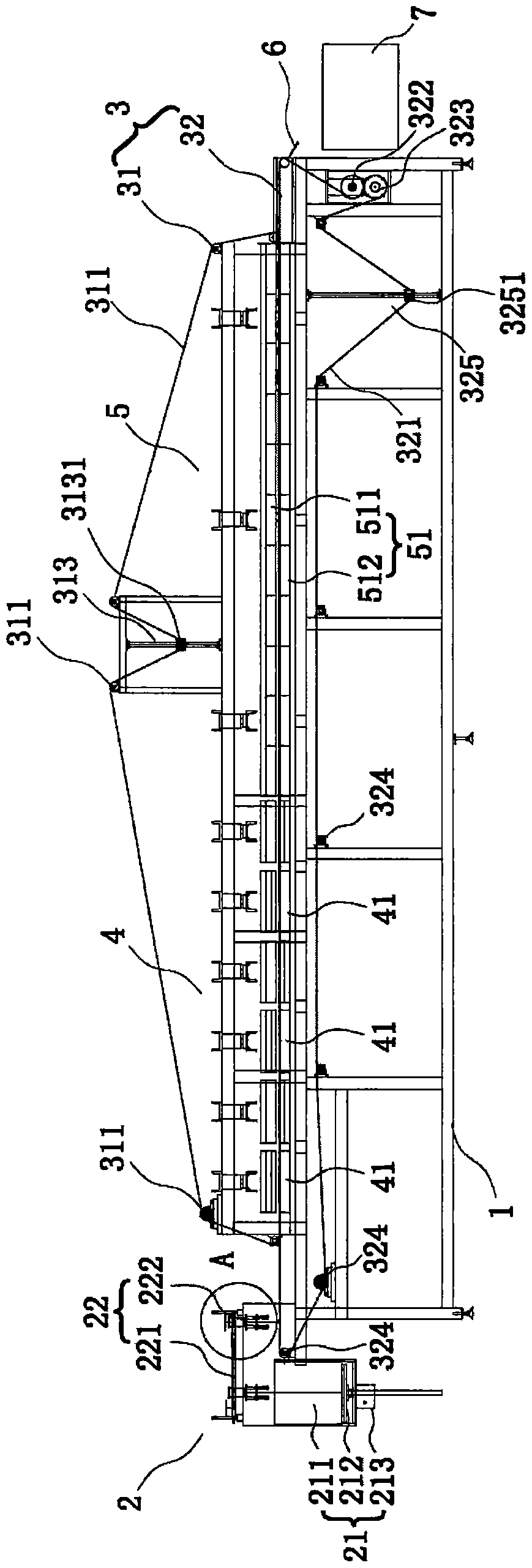

[0032]The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

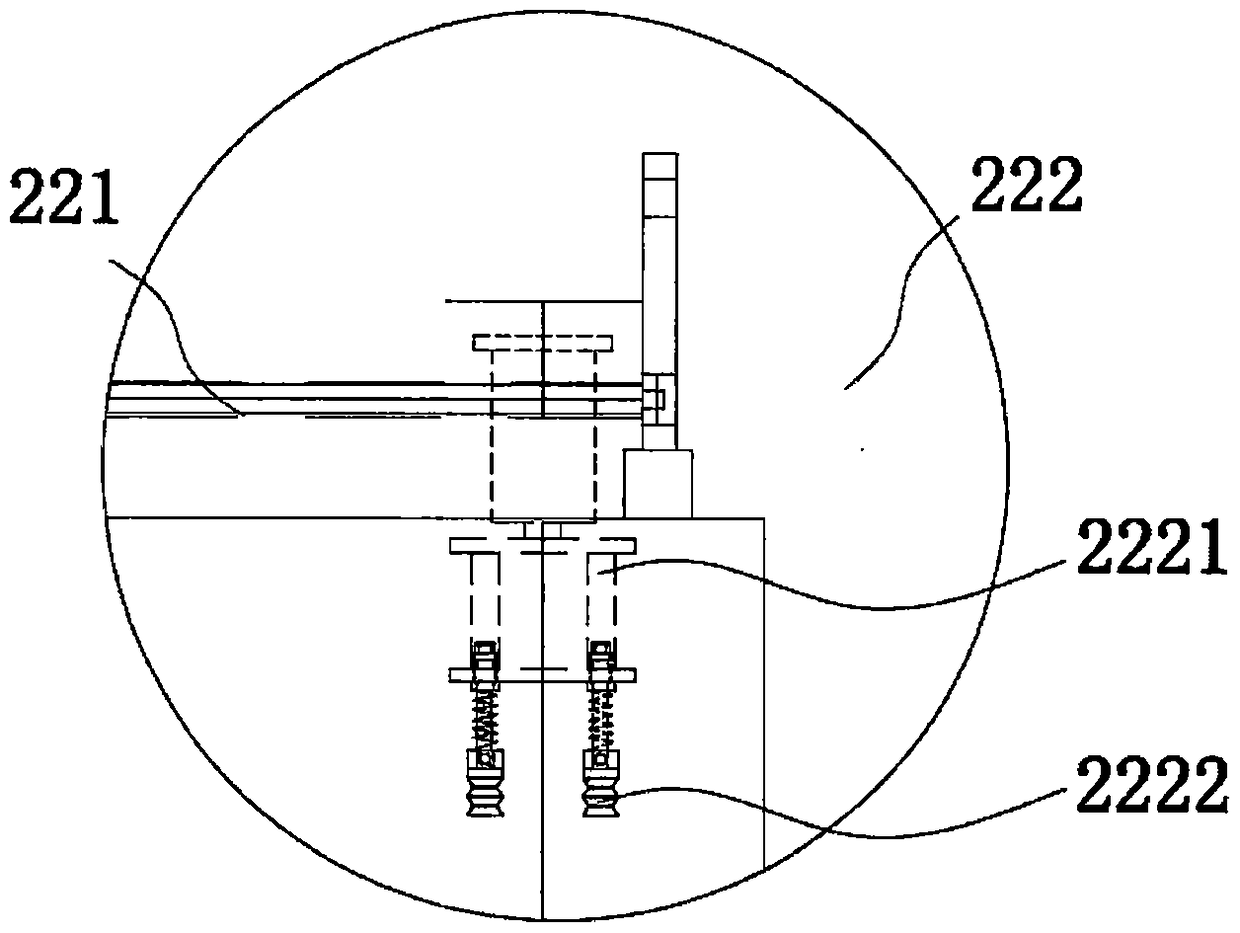

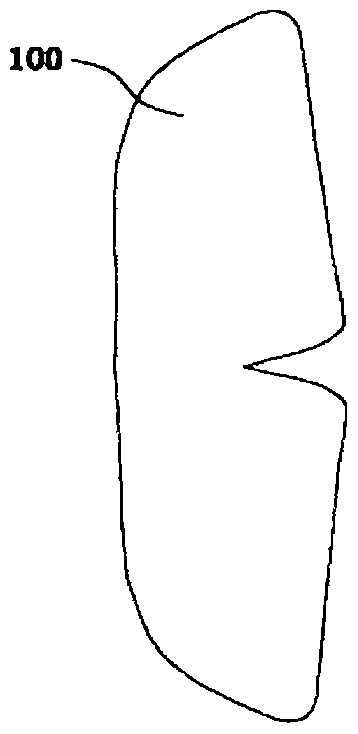

[0033] Such as figure 1 Shown, the present invention is a kind of shoe front liner / rear cover processing machine, in conjunction with reference image 3 with Figure 4 , the present invention is used to process the edge of the semi-finished shoe front liner / back cover after cutting, so that the edge of the shoe front liner / back cover is gradually thinned, and the chamfering is completed, so as to improve the appearance, stitching quality and sewing efficiency. The shoe front lining / rear cover processing machine of the present invention comprises a machine platform 1, and the said machine platform 1 is equipped with a discharge system 2, a conveying system 3, a hot pressing forming system 4, a cooling system 5 and a demoulding device 6, wherein:

[0034] The feeding system 2 is used to place the shoe front l...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap