Perforating and embossing forming mold

A forming mold and hole pressing technology, which is applied in the fields of medical science, clothing, underwear, etc., can solve problems such as inability to guarantee synchronization, difficulty in achieving precise positioning, deviation of embossing and punching positions, etc., to improve alignment difficulties, Facilitate penetration and absorption, prevent side leakage and back leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

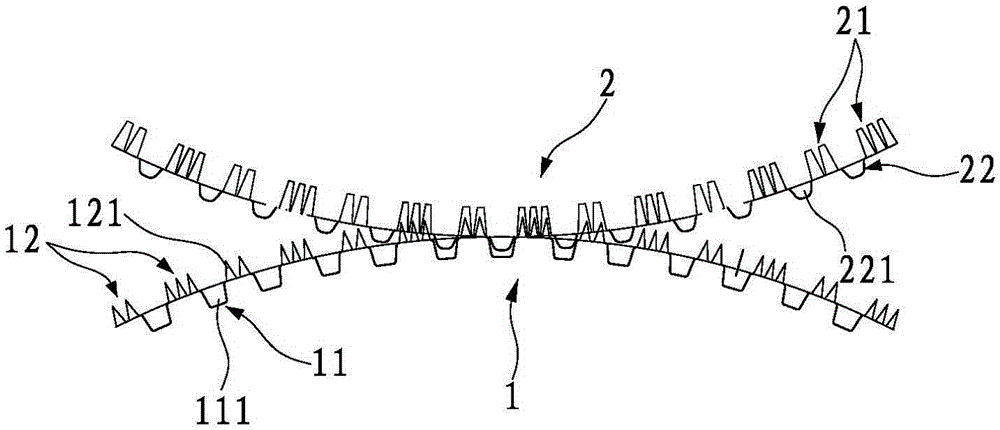

[0032] Such as Figure 4 , shown in 5, the punching and embossing molding die of the present invention comprises a convex roll 4 and a concave roll 5 that are engaged with each other, wherein the convex roll 4 has a perforated area 41 and a counterbore area 42, and the perforated area 41 Contains 1 tine, the bottom of the tine has a circular cross-section with an area of 3.14mm 2 , with a height of 3.0 mm, the counterbore area 42 includes a counterbore, the punched area 41 and the counterbore area 42 are spaced apart from each other; the concave roller 5 has a concave area 51 and a raised area 52, and the convex The raised area 52 includes a protrusion, the cross section of the bottom of the protrusion is circular, and the area is 7.07mm 2 , with a height of 3.5 mm, the concave hole area 51 corresponds to the perforated area 41 , and the raised area 52 corresponds to the counterbore area 42 . Both the convex roll 4 and the concave roll 5 are equipped with heating devices. ...

Embodiment 2

[0036] Such as Figure 6, shown in 7, the punching and embossing molding die of the present invention comprises a convex roller 6 and a concave roller 7 that are engaged with each other, wherein the convex roller 6 has perforated areas 61, 62 and counterbore areas 63, and the punched The hole areas 61, 62 include a plurality of tines of different needle shapes, and the cross section of the bottom of the tines in the tines area 61 is circular with an area of 3.14mm 2 , with a height of 3.0 mm, the cross-section of the bottom of the tine in the tine area 62 is circular, with an area of 1.13 mm 2 , with a height of 2.5 mm, the counterbore area 63 includes a dumbbell-shaped counterbore, the perforated areas 61, 62 and the counterbore area 63 are spaced apart from each other; the concave roller 7 has concave hole areas 71, 72 and protrusions Area 73, the raised area 73 includes a dumbbell-shaped protrusion, the cross-section of the raised bottom is dumbbell-shaped, the area is...

Embodiment 3

[0039] Such as Figure 8 , shown in 9, the punching and embossing molding die of the present invention comprises a convex roller 8 and a concave roller 9 that are engaged with each other, wherein the convex roller 8 has a perforated area 81 and a counterbore area 82, and the perforated area 81 contains a plurality of tines of the same needle shape, the cross-section of the bottom of the tines is circular, and the area is 2.01mm 2 , with a height of 2.5mm, the counterbore area 82 includes a plurality of counterbores, the perforated area 81 and the counterbore area 82 are spaced apart from each other; the concave roller 9 has a concave area 91 and a raised area 92, and the convex The raised area 92 comprises a plurality of protrusions, and the cross-section of the bottom of the protrusions is elliptical and has an area of 15 mm. 2 , with a height of 3.5 mm, the concave hole area 91 corresponds to the perforated area 81 , and the raised area 92 corresponds to the counterbore a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com