Absorption article and manufacturing method thereof

A technology for absorbent articles and manufacturing methods, applied in the field of sanitary products, can solve problems such as side effects, easy reverse osmosis secretions, and peculiar smells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

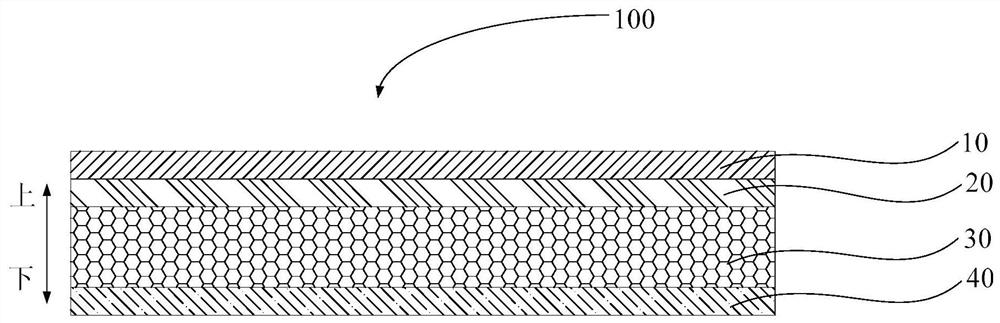

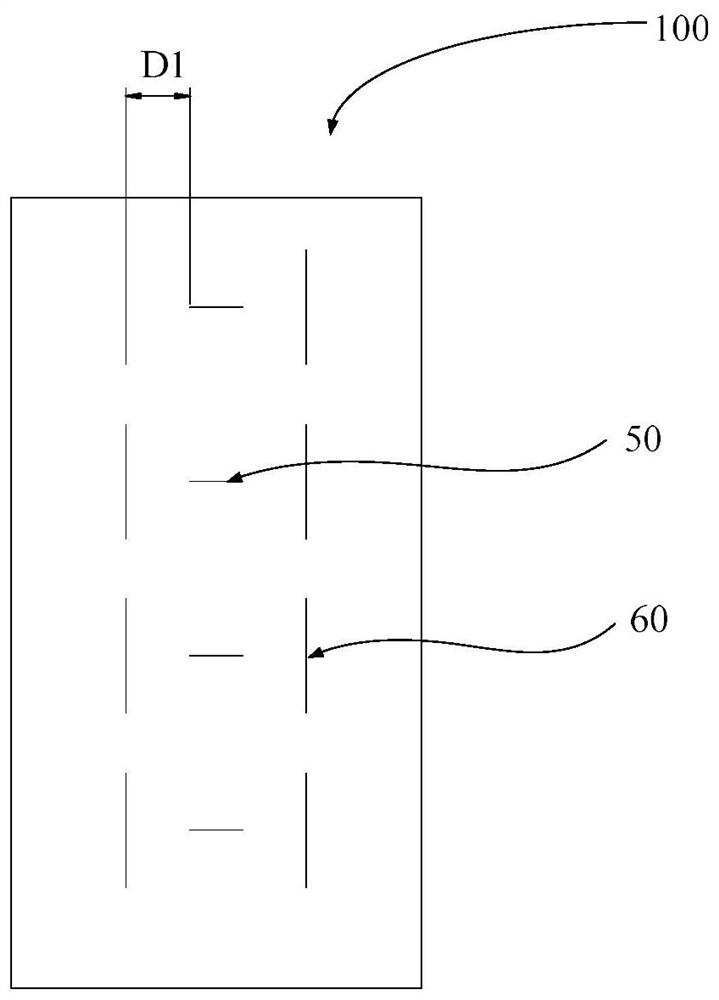

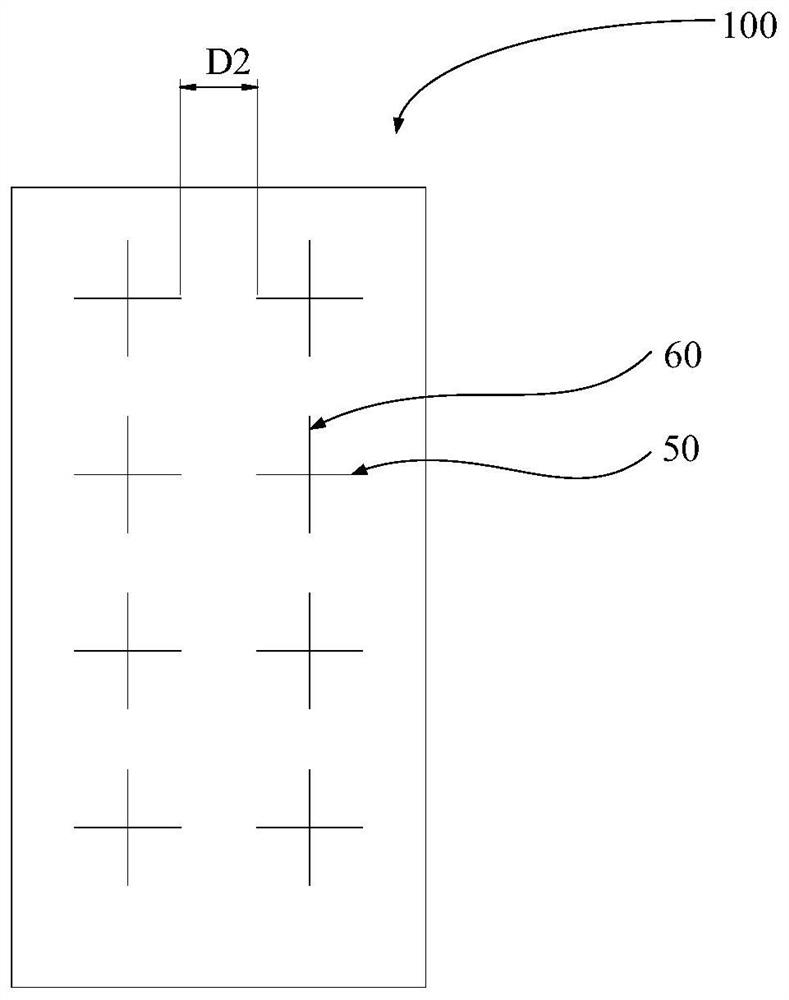

[0095] An absorbent article, comprising a liquid-permeable surface layer, an antibacterial covering layer, an absorbent portion, and a breathable bottom layer arranged in sequence. The absorbent part is provided with a plurality of transverse slits and longitudinal slits passing through the absorbent part, the transverse slits are perpendicular to the longitudinal slits, the transverse slits are arranged along the width direction of the absorbent part, and the longitudinal slits are arranged along the lengthwise direction of the absorbent part. The liquid-permeable surface layer is made of hydrophilic non-woven fabric layer. The bacteriostatic covering layer includes a substrate and a bacteriostatic composition uniformly distributed on the substrate, and the bacteriostatic composition includes the following components by weight: 2-15 parts of tea leaves; 3-10 parts of cloves. The wrapping layer of the absorbing part is a layer of high water-absorbing resin composite paper made...

Embodiment 2

[0097] An absorbent article, comprising a liquid-permeable surface layer, an absorbent portion, and a breathable bottom layer arranged in sequence. The liquid-permeable surface layer is made of hydrophilic non-woven fabric layer. The wrapping layer of the absorbing part is a layer of high water-absorbing resin composite paper made by wet process. The absorbing layer of the absorbing part is at least one layer of wet-process superabsorbent resin composite paper or fluff pulp mixed superabsorbent resin or dry-process absorbent paper or five-layer composite core. The breathable bottom layer is PE breathable film.

Embodiment 3

[0099] An absorbent article, comprising a liquid-permeable surface layer, an absorbent portion, and a breathable bottom layer arranged in sequence. The liquid-permeable surface layer is made of hydrophilic non-woven fabric layer. The wrapping layer of the absorbent part is dust-free paper or wet-strength paper. The absorbent layer of the absorbent part is made of fluff pulp mixed with super absorbent resin. The breathable bottom layer is PE breathable film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com