Ammonia water clarifying tank

A technology of clarifier and ammonia water, applied in sedimentation tanks, liquid separation, chemical instruments and methods, etc., can solve problems such as affecting product quality, affecting the normal operation of coke ovens, increasing production and processing costs, etc., to reduce the settling distance and the separation effect. Good, easy loading and unloading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

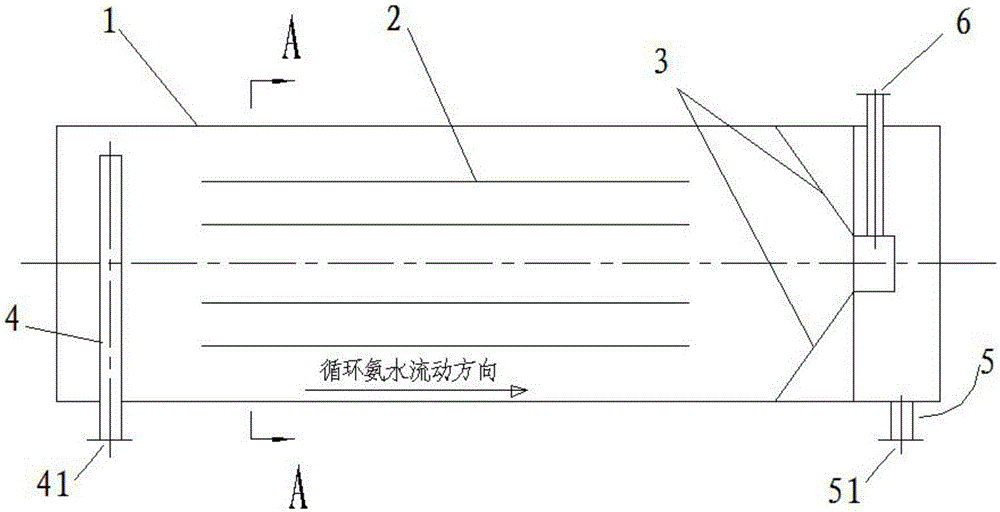

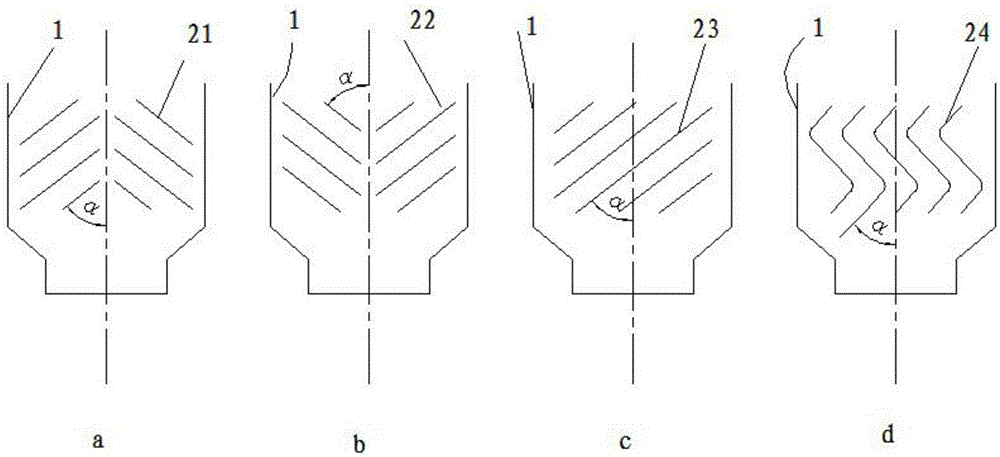

[0023] combine figure 1 , figure 2 , a kind of ammonia clarification tank, comprises rectangular settling tank casing 1, and one end of described casing 1 is provided with circulating ammonia entering pipeline 4, and the other end is provided with circulating ammonia discharge pipeline 5, and described circulating ammonia enters the inlet of pipeline 4, The outlet of the circulating ammonia water discharge pipeline 5 is located at the lower part of the box body, and a settling plate group 2 is arranged in the settling tank box body 1, and the settling plate group 2 is arranged along the flowing direction of the circulating ammonia water, that is, along the rectangular settling tank of the ammonia water clarification tank. Arranged in the long side direction, the settling plate group d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com