Liquid atomizing spraying device and hairdressing electric sprinkling can with same

A liquid atomization and watering can technology, which is applied to liquid spray devices, spray devices, spray devices, etc., can solve the problems of low atomization efficiency of nozzles, low work efficiency, inconvenient use, etc., and achieve the effect of improving low atomization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

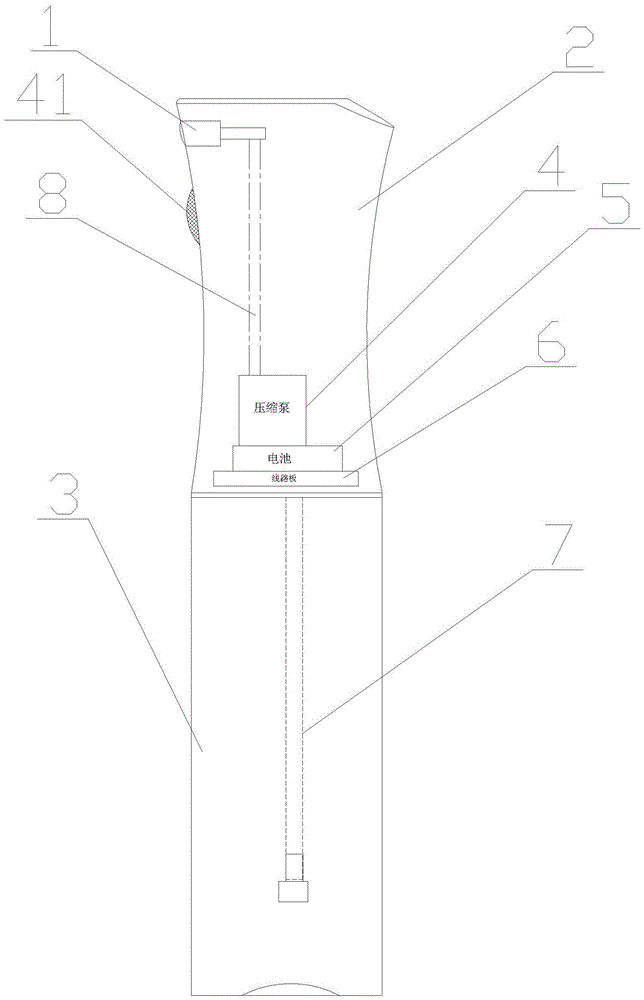

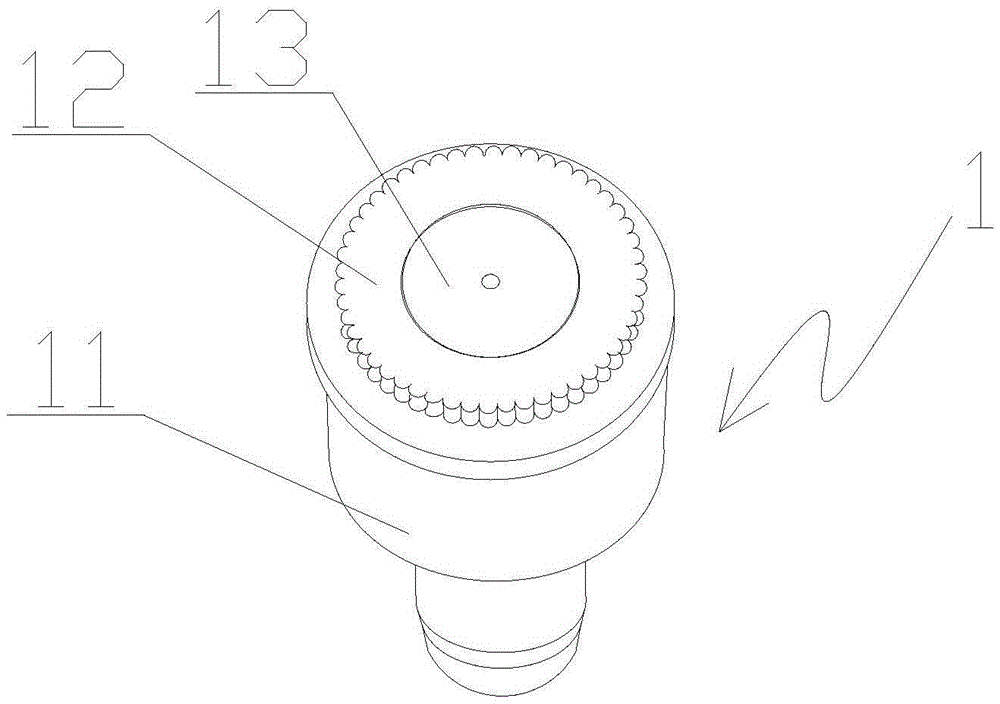

[0040] Figure 1 to Figure 7 An electric watering can for hairdressing according to one embodiment of the present invention is schematically shown. As shown in the figure, the device includes a nozzle 1 , a spray head 2 and a pot body 3 .

[0041] The spray head 2 is connected with the pot body 3 through threads.

[0042] The spray head 2 and the pot body 3 are both streamlined and ergonomically designed.

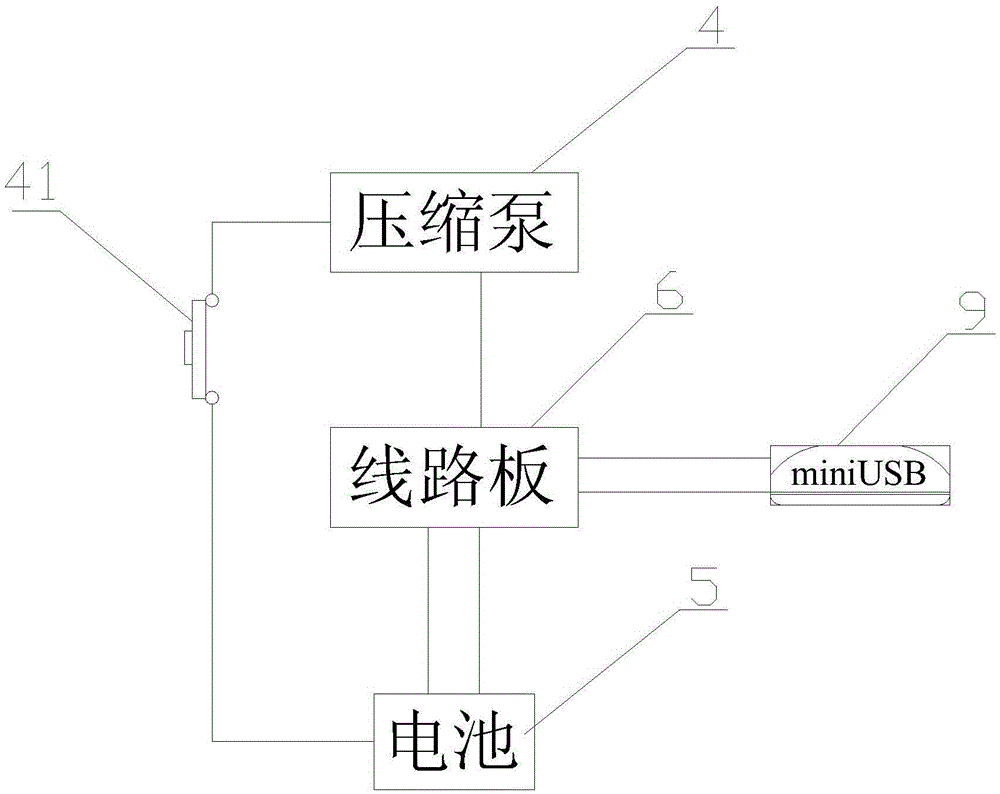

[0043] A compression pump 4 and a battery 5 for supplying power to the compression pump 4 are installed inside the spray head 2 .

[0044] The battery 5 is a rechargeable battery, and a circuit board 6 for controlling the charging and discharging state of the battery 5 is also provided inside the spray head 2 . The circuit board 6 is connected to the 5V DC power supply through the miniUSB charging interface 9 provided on the nozzle. Thus, the battery 5 can be charged by using a mobile phone charger.

[0045] The battery 5 is connected to the compression pump 4 through ...

Embodiment 2

[0069] Figure 8 An electric watering can for hairdressing according to another embodiment of the present invention is schematically shown. The difference from Embodiment 1 is that the battery 5 is charged by the wireless charging device 10 . As shown in the figure, the wireless charging device 10 includes a receiving plate 101 arranged inside the spray head and a charging plate 102 matching with the receiving plate 101 .

[0070] The charging board 102 is connected to an external AC220V power supply. The charging pad 102 is provided with a primary coil. The receiving plate 101 is provided with a secondary coil. The primary coil generates an alternating current of a certain frequency, and current is generated in the secondary coil through electromagnetic induction, so as to transmit electric energy to the circuit board 6 for charging the battery 5 . As a result, the spray head part of the electric watering can for hairdressing does not need to be provided with a charging p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap