High dispersion type vortex powder selecting machine

A technology of high dispersion and powder separator, which is applied in the direction of solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc. It can solve the problem of unsatisfactory dispersion effect, uneven thickness of material curtain, and influence on powder selection. Efficiency and other issues, to achieve high classification accuracy, high powder selection efficiency, and improve the effect of powder selection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

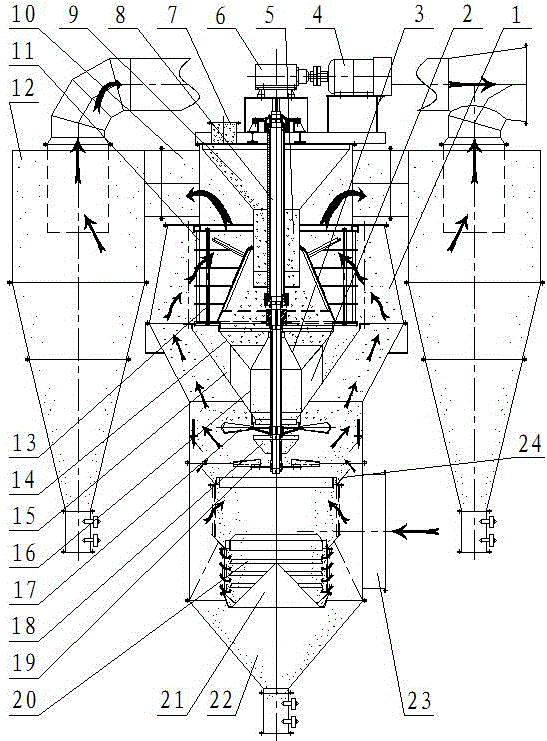

[0014] figure 1 Medium and high dispersion type eddy current powder separator, including shell 1, feeding pipe 7, coarse powder collecting cone 22, motor 4, reduction box 6, transmission shaft 8, spreading disc 17, guide vane 11, cage rotor 13. Both the motor 4 and the reduction box 6 are arranged on the top of the housing 1, and the motor 4 is connected to the reduction box 6. The upper end of the transmission shaft 8 is connected with the reduction box 6 , and the lower end of the transmission shaft 8 passes through the top of the housing 1 and is located in the housing 1 . The cage rotor 13 is arranged on the transmission shaft 8, and the spreading disc 17 is arranged on the transmission shaft 8 and is positioned under the cage rotor 13. The outer side of the cage rotor 13 is equipped with a circle of the guide blades 11, and the feed pipe 6 is arranged on the top of the housing 1, and the coarse powder collecting cone 22 is arranged on the lower end of the housing 1. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com