Quick milling positioning device

A positioning device, milling technology, applied in the direction of positioning device, clamping, support, etc., can solve the problems of low processing efficiency of parts, difficulty in meeting assembly requirements, and accumulated errors, etc., to achieve improved processing efficiency, high processing accuracy, and product quality. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

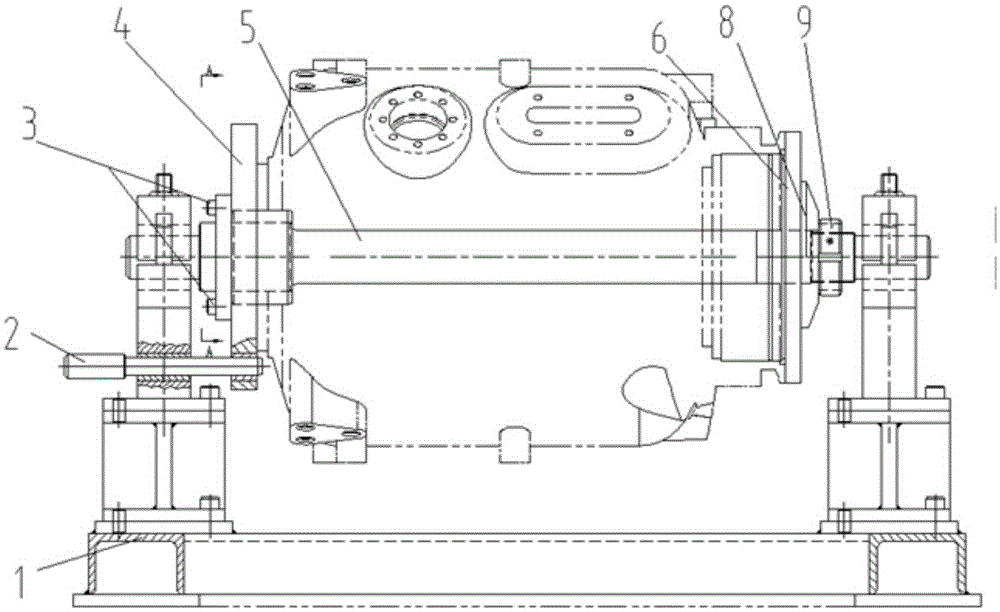

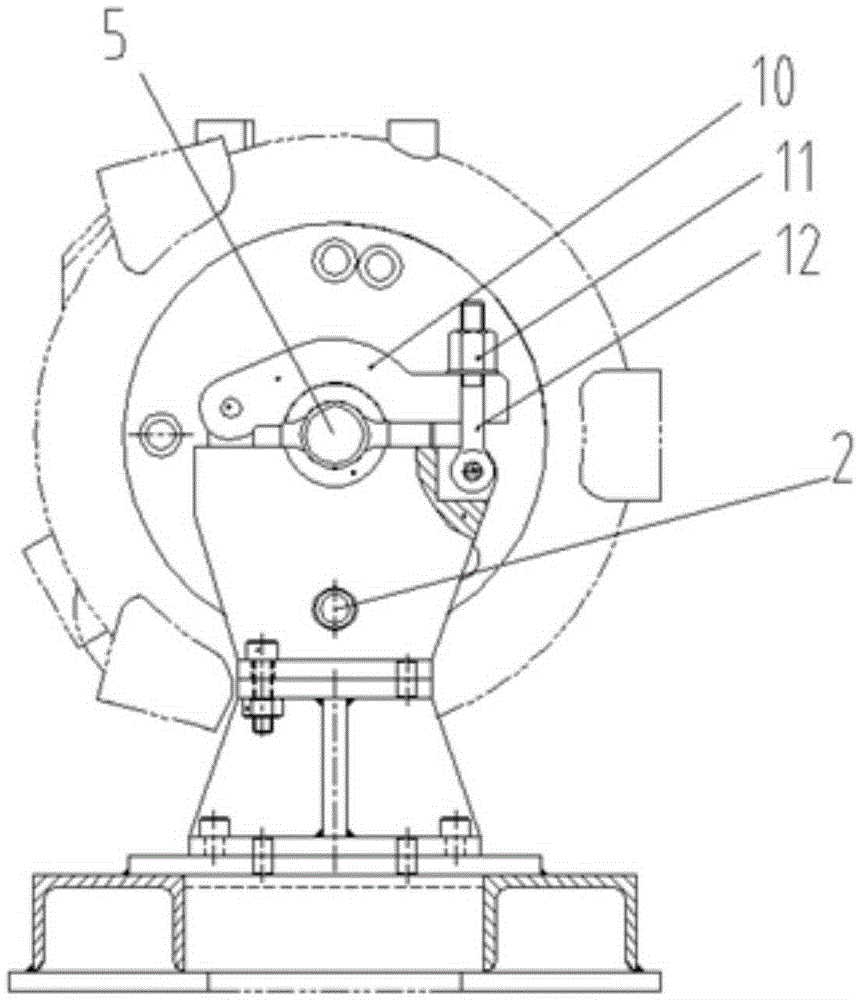

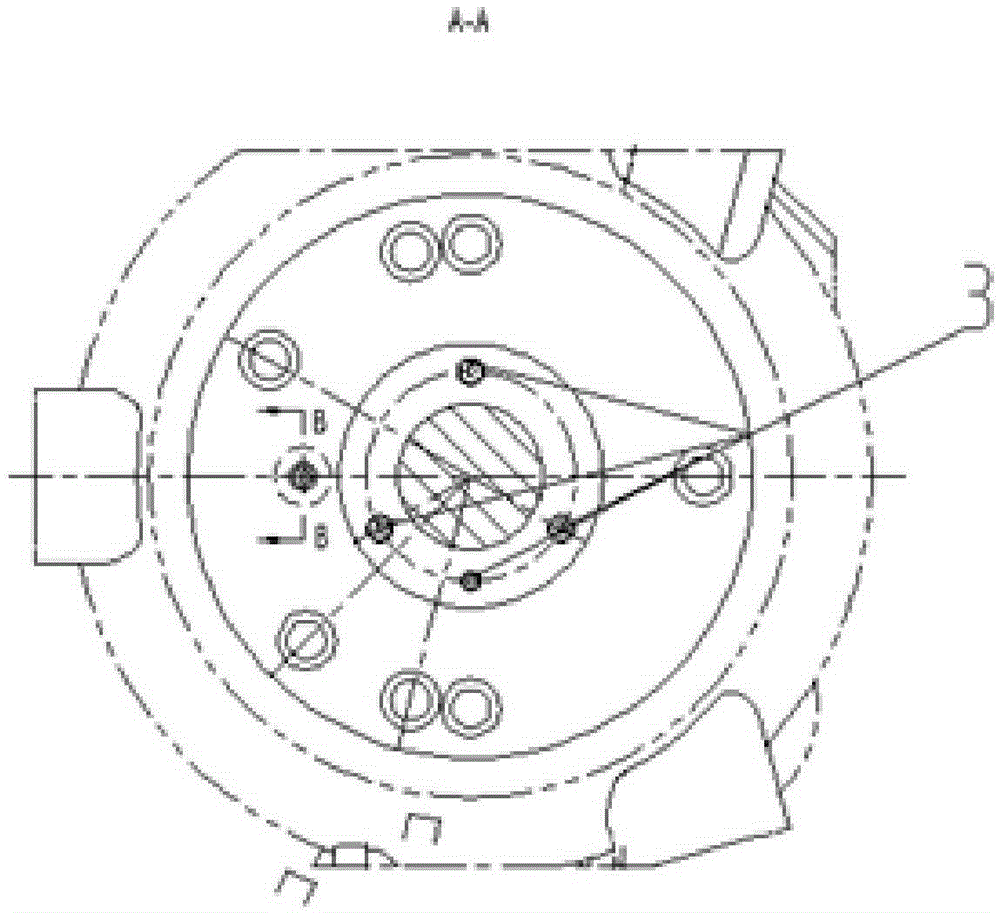

[0013] A rapid milling positioning device, the device includes a bracket 1, a positioning pin 2, a left end cover 4, a positioning shaft 5, a right end cover 6, an enlarged opening washer 8 and a rotary pressure plate 10, wherein the positioning shaft 5 can pass through the parts The two ends of the shaft hole can be fixed on the two side arms of the bracket 1; the left end cover 4 is threaded with the left end of the positioning shaft 5, and several hexagon socket screws 3 are threaded with the left end cover 4 so as to apply pressure to the parts through rotation; The right end cover 6 penetrates from the right end of the positioning shaft 5, and on its outer side is an enlarged washer 8 and a round nut 9, which apply pressure to the parts by rotating the round nut 9; the positioning pin 2 passes through the support on the left side. Arm with left end cap4.

[0014] On the left end cover 4, the positioning pin 7 is used to limit the parts.

[0015] There are rotary pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com