Novel modified asphalt waterproof roll and preparation method thereof

A waterproof membrane and modified asphalt technology, applied in asphalt layered products, chemical instruments and methods, lamination, etc., can solve the problems of insufficient tensile strength, poor impact resistance, and low waterproof performance of modified asphalt, etc. Achieve the effect of low manufacturing cost, good impact resistance and good waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

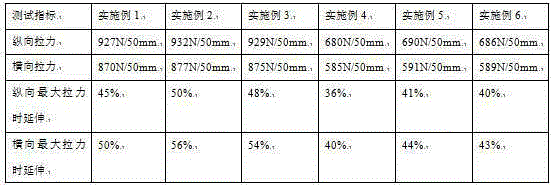

Embodiment 1

[0037] Example 1 A new type of modified bitumen waterproof membrane

[0038] 1. Composition of waterproof membrane

[0039] The waterproof roll material includes polyester tire, prepreg, coating material and isolation material;

[0040] The thickness of the waterproof membrane is 3mm;

[0041] (1) The polyester tire mentioned above: it is a long-fiber polyester tire with a basis weight of 200g / ㎡ and a thickness of 1.1mm;

[0042] (2) The prepreg includes the following components in parts by weight: 89.5 parts of heavy traffic asphalt, 5 parts of rubber, 5 parts of mineral filler, and 0.5 parts of anti-aging agent;

[0043] The heavy traffic asphalt is No. 70 heavy traffic asphalt;

[0044] The rubber is SBS501;

[0045] Described mineral filler is talcum powder;

[0046] The anti-aging agent is anti-aging agent 4010, that is, N-cyclohexyl-N'-phenyl-p-phenylenediamine, which is a p-phenylenediamine anti-aging agent;

[0047] (3) The coating material includes the followin...

Embodiment 2

[0076] Example 2 A new type of modified bitumen waterproof membrane

[0077] 1. Composition of waterproof membrane

[0078] The waterproof roll material includes polyester tire, prepreg, coating material and isolation material;

[0079] The thickness of the waterproof membrane is 4mm;

[0080] (1) The polyester tire mentioned above: it is a long-fiber polyester tire with a basis weight of 200g / ㎡ and a thickness of 1.0mm;

[0081] (2) The prepreg includes the following components in parts by weight: 60 parts of heavy traffic asphalt, 20 parts of rubber, 2 parts of mineral filler, and 2 parts of anti-aging agent;

[0082] The heavy traffic asphalt is No. 70 heavy traffic asphalt;

[0083] The rubber is SBS501;

[0084] Described mineral filler is talcum powder;

[0085] The anti-aging agent is anti-aging agent 4010, that is, N-cyclohexyl-N'-phenyl-p-phenylenediamine, which is a p-phenylenediamine anti-aging agent;

[0086] (3) The coating material includes the following ...

Embodiment 3

[0115] Example 3 A new type of modified bitumen waterproof membrane

[0116] 1. Composition of waterproof membrane

[0117] The waterproof roll material includes polyester tire, prepreg, coating material and isolation material;

[0118] The thickness of the waterproof membrane is 5mm;

[0119] (1) The polyester tire mentioned above: it is a long-fiber polyester tire with a basis weight of 200g / ㎡ and a thickness of 1.1mm;

[0120] (2) The prepreg includes the following components in parts by weight: 78 parts of heavy traffic asphalt, 30 parts of rubber, 15 parts of mineral filler, and 3 parts of anti-aging agent;

[0121] The heavy traffic asphalt is No. 70 heavy traffic asphalt;

[0122] The rubber is SBS501;

[0123] Described mineral filler is talcum powder;

[0124] The anti-aging agent is anti-aging agent 4010, that is, N-cyclohexyl-N'-phenyl-p-phenylenediamine, which is a p-phenylenediamine anti-aging agent;

[0125] (3) The coating material includes the following...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Base weigh | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com