A foundation braking device for a railway freight car bogie

A basic braking device and railway freight car technology, applied in the direction of railway braking system, operating mechanism of railway vehicle brake, railway car body parts, etc., can solve the problem of not meeting the requirements of railway freight car bogie, vehicle braking and alleviate adverse effects and other problems, to achieve the effect of improving the braking effect, preventing deviation, and avoiding the middle limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

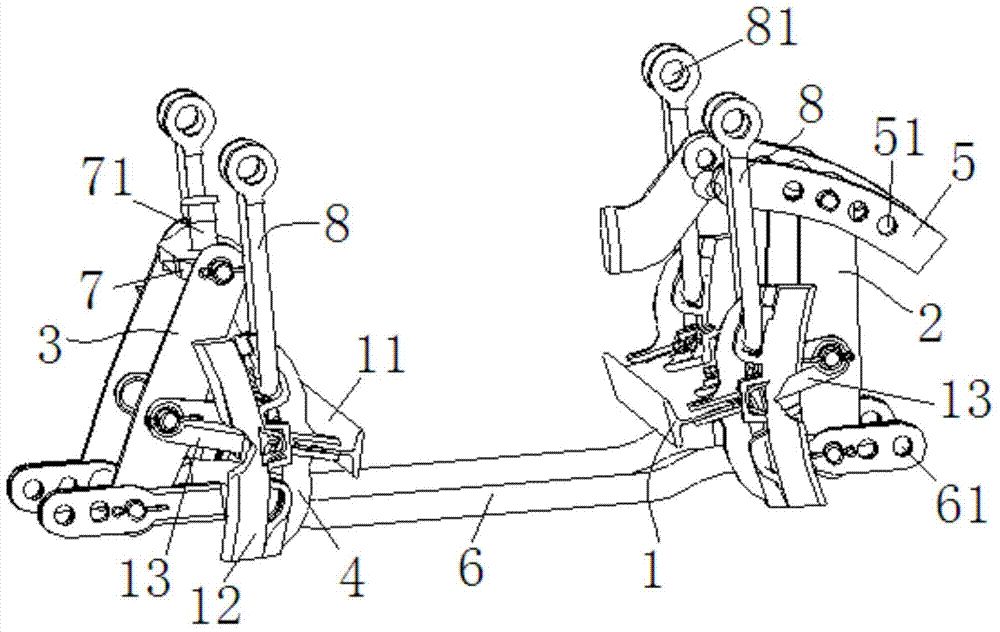

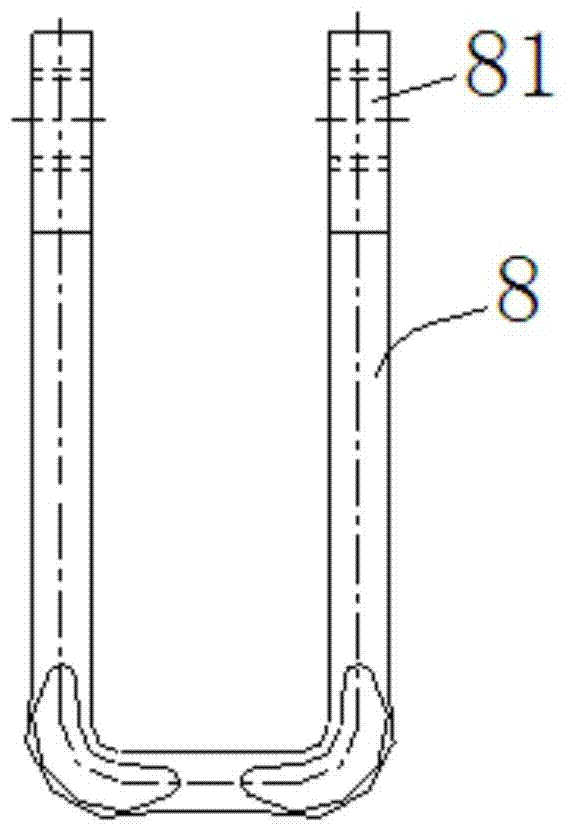

[0018] Such as figure 1 As shown, the present invention proposes a foundation braking device for a railway freight car bogie, which includes two brake beams 1, two pairs of brake levers 2, 3, four brake shoes 4, and two fixed lever fulcrums 5 , two pull-down rods 6 and a connecting beam 7. Wherein, two brake beams form 1 and are arranged in parallel and symmetrically.

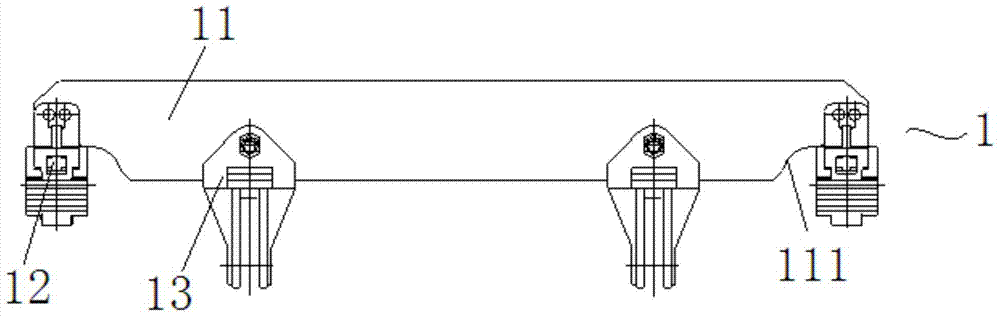

[0019] Each brake beam assembly 1 includes a brake beam frame 11, a brake shoe holder 12 is fastened to both ends of the brake beam frame 11, and two pillars are fastened to one side of the brake beam frame 11 at intervals. One end of 13 (such as figure 2 shown). The four brake shoes 4 are fastened to the four brake shoe holders 12 respectively.

[0020] The two pull-down rods 6 are arranged in parallel at intervals, one end of the two pull-down rods 6 is hinged to the bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com