Construction method of rapid dismantling and replacement of large tonnage marine propellers

A technology of marine propeller and construction method, which is applied in the directions of ship parts, ship construction, ship design, etc., can solve the problems of difficulty in operation, increase the number of scraping and grinding, and reduce the quality of propeller assembly, so as to meet the adjustment needs of spatial position status. , Safety risk prevention is easy to control, and the effect of reducing the difficulty of installation and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

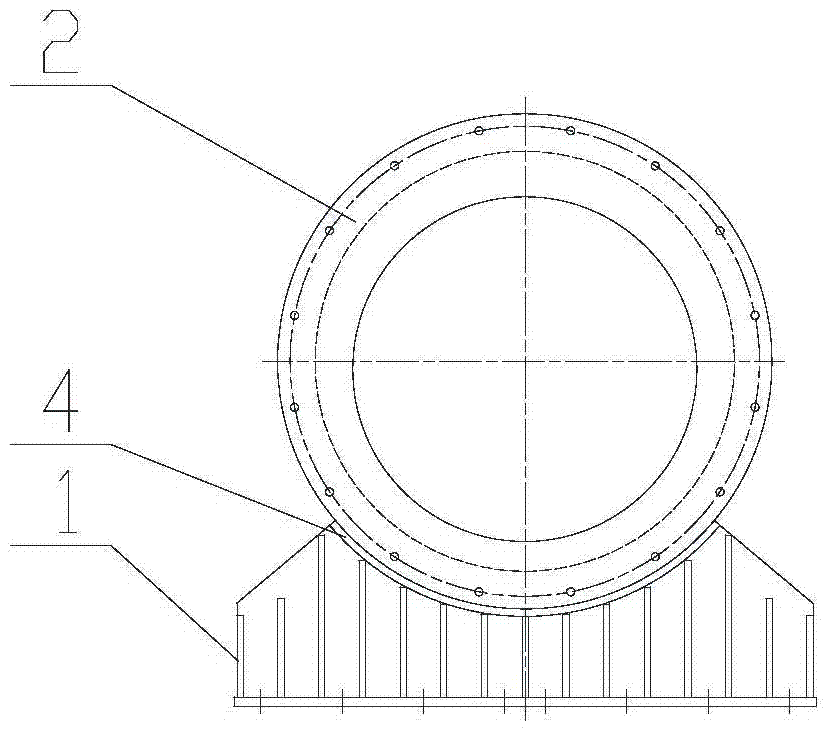

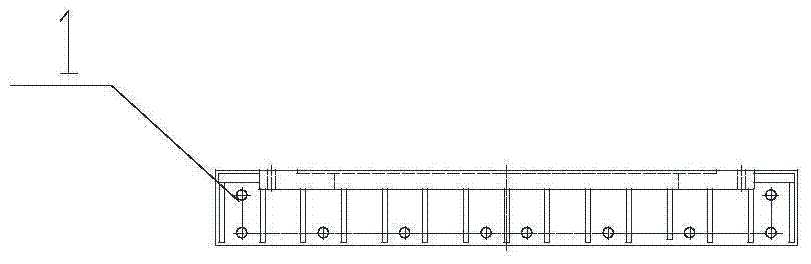

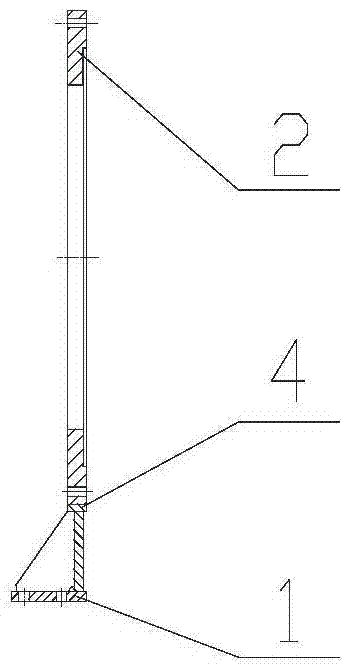

[0126] Take the propeller renewal of the 13,000-TEU container ship "Sarnia" of Maersk's ERS series as an example.

[0127] After the ship has completed the small resistance bulbous bow replacement, in order to achieve the best performance matching of the ship, engine and propeller, further reduce the fuel consumption of the ship, and improve the shipping economy of the ship, it is necessary to replace the propeller. Its main engineering quantity includes: dismantling the old 6-blade propeller with a diameter of 9 meters and a weight of 110.3 tons, shifting it on the back, and hoisting it out of the dock; and then completing the assembly of a new 5-bladed propeller with a diameter of 9.4 meters and a weight of 86 tons.

[0128] Such as Figure 14-Figure 17 As shown, the specific construction method is as follows:

[0129] 1. Design, manufacture and connection assembly of general steel bracket and propeller hub support seat:

[0130] According to the size of the hub length, bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com