Liquid storage tank group

A technology for liquid storage tanks and liquid intake, which is applied in the direction of tanks/barrels/barrels, rigid containers, containers, etc. Large quantities and other problems, to achieve the effect of solving large footprint, reducing floor space, faster and more accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to have a clearer understanding of the technical solutions, objectives and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

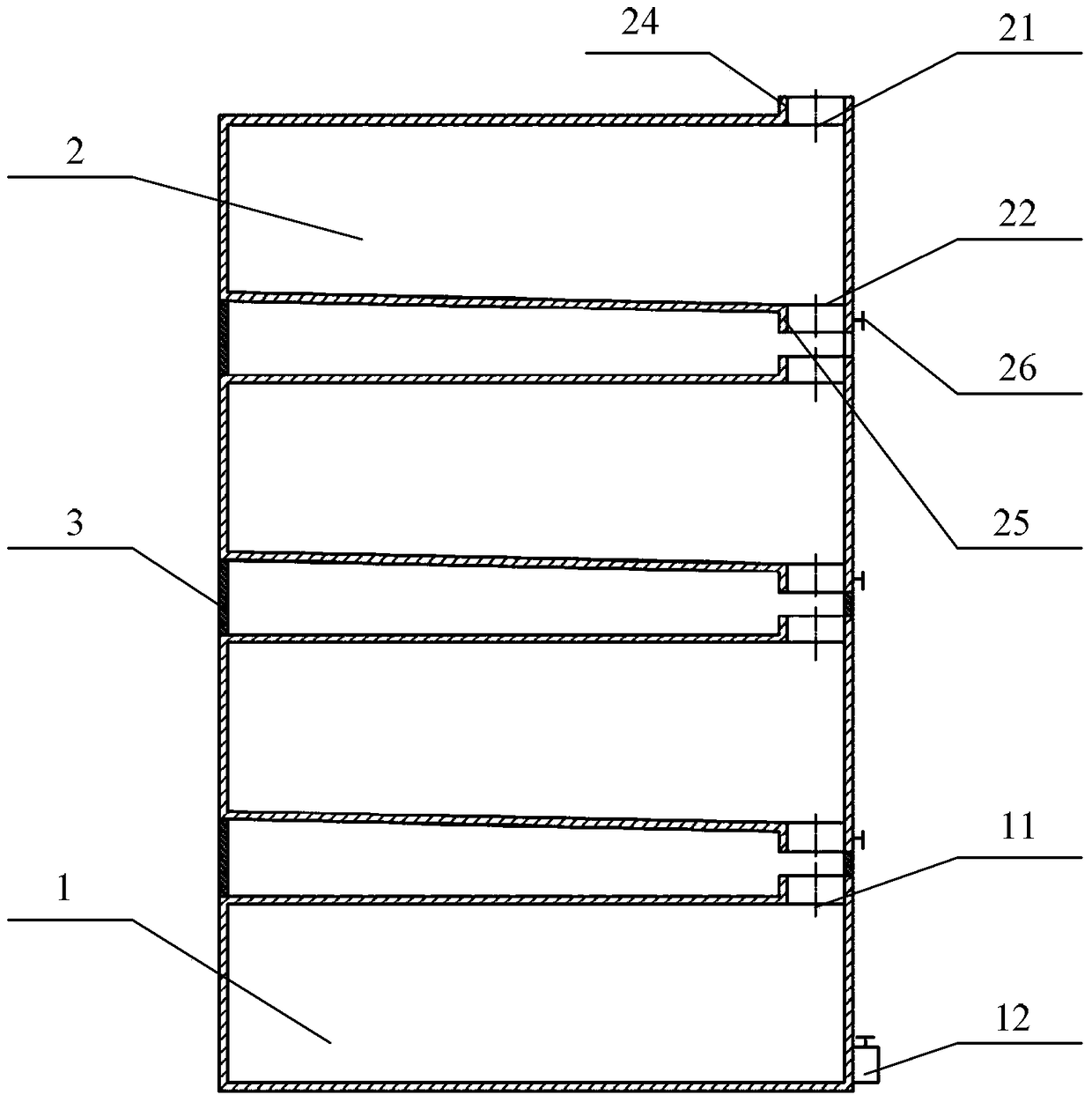

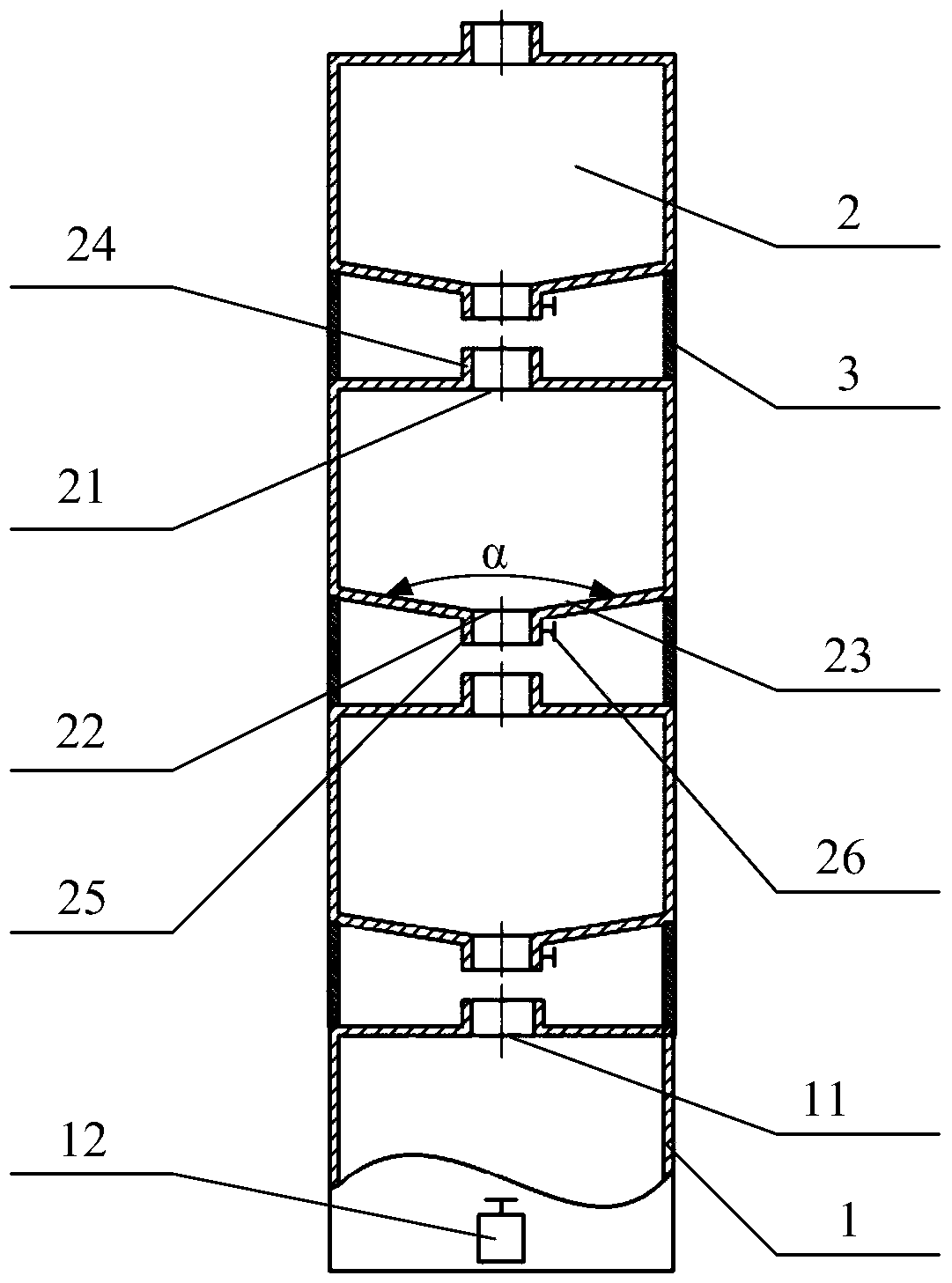

[0022] Such as figure 1 and figure 2 As shown, the present invention provides a liquid storage tank group, which includes a bottom liquid storage tank 1 and at least two liquid storage tank units 2 stacked sequentially from bottom to top, and the stacking method greatly reduces the pressure of the liquid storage tank group. The footprint of the liquid storage tank group is not affected by the footprint of the well site. The bottom surface of the bottom liquid storage tank 1 is a plane and can be directly placed on the well site. The top surface is provided with a liquid inlet through hole 11, and the lower part of the side wall of the bottom liquid storage tank 1 is provided with a liquid discharge through hole 12. The liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com