Electric control automatic loading and unloading shelf

An automatic loading and unloading and racking technology, applied in the field of storage racks, can solve the problems of difficulty in meeting the needs of small and medium-sized storage enterprises, high requirements for equipment installation accuracy, and difficulty in large-scale promotion and use, and achieves a simple structure, simple and stable structure, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

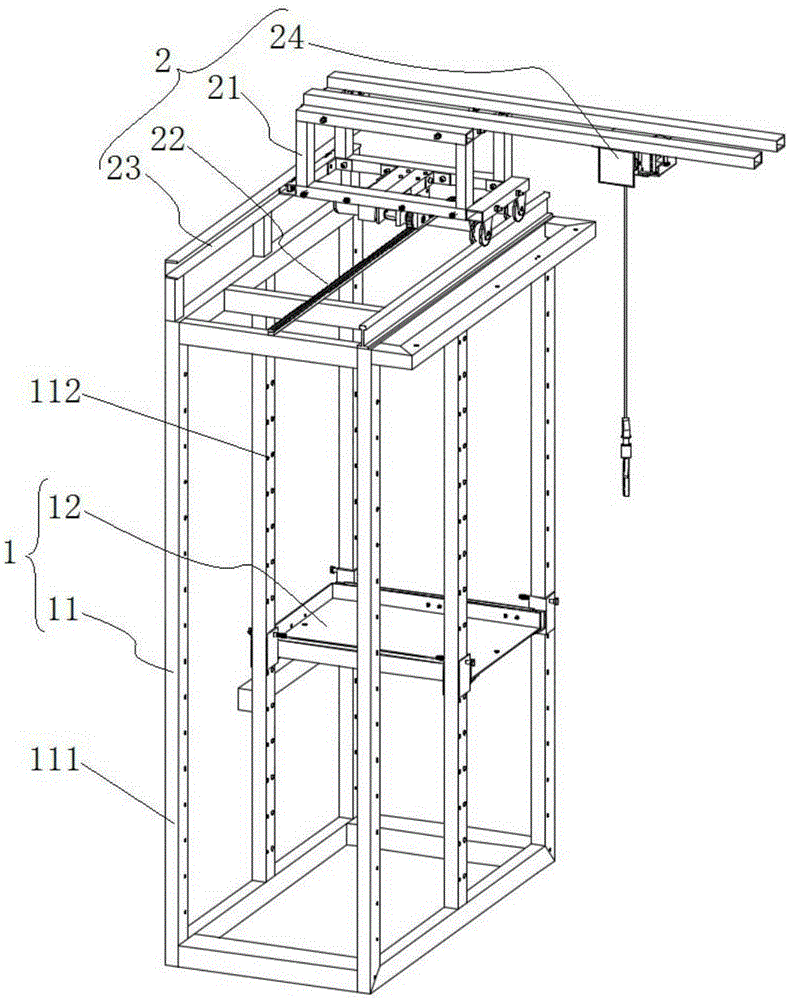

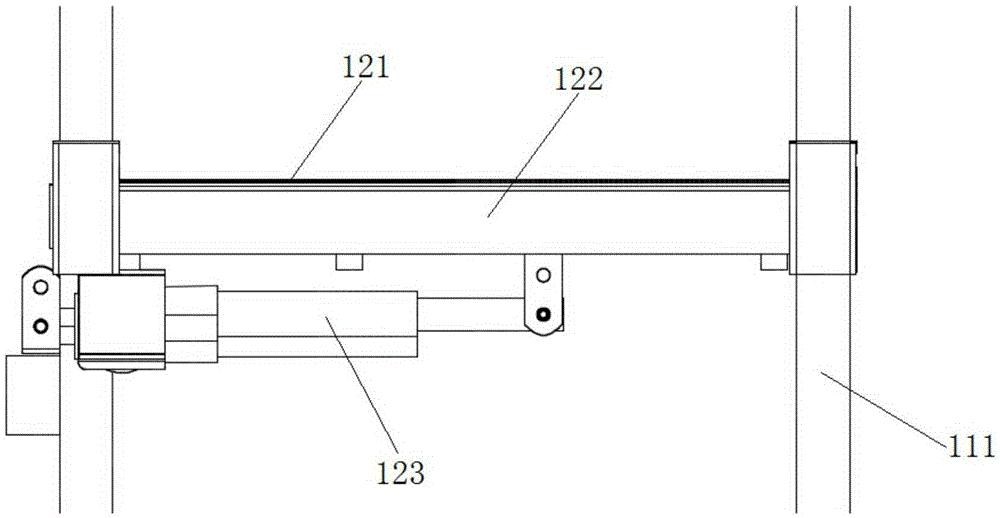

[0031] combine figure 1 As shown, an electric control automatic loading and unloading shelf in this embodiment includes a storage shelf 1, and an electric control trolley 2 is arranged on the top of the storage shelf 1, and the electric control trolley 2 can move in the transverse direction of the storage shelf 1 throughout the whole process. , so the entire storage shelf 1 can be covered to realize loading and unloading of goods at various positions of the storage shelf 1 .

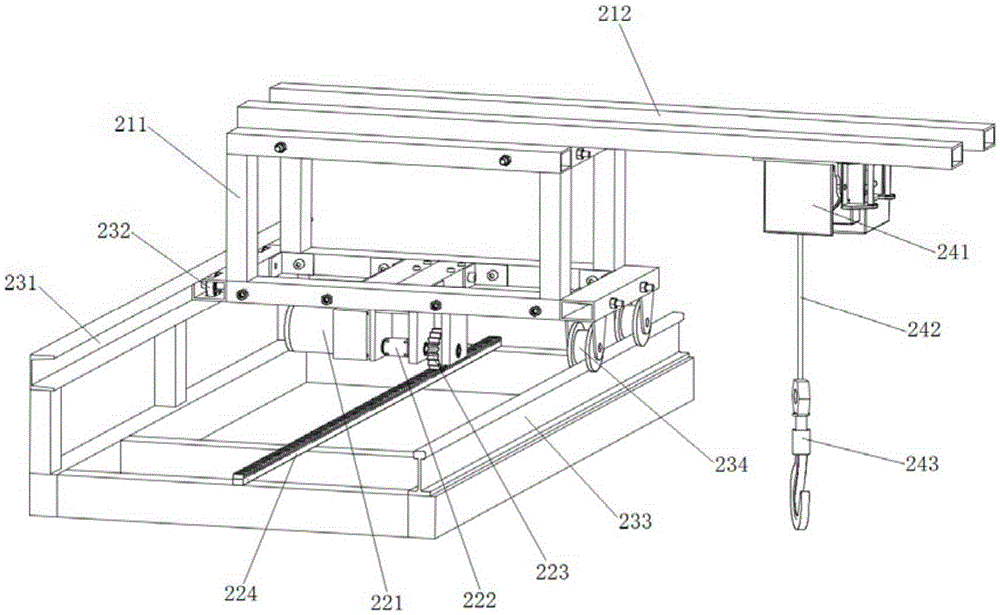

[0032] Wherein, the electronically controlled trolley 2 in the present embodiment comprises a car body 21, a driving mechanism 22, a guide mechanism 23 and a lifting mechanism 24, and the car body 21 is installed on the top of the storage shelf 1 through a laterally arranged guide mechanism 23, and the driving mechanism 22 is installed on the vehicle body 21, and is used to drive the vehicle body 21 to slide laterally on the guide mechanism 23. A suspension rod 212 extends outward from the vehicle body 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com